2022:Intake: Difference between revisions

Mechanical1 (talk | contribs) No edit summary Tag: visualeditor |

Mechanical1 (talk | contribs) No edit summary Tag: visualeditor |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 57: | Line 57: | ||

== CRUNCH time before Rally!! 2/17/2022-2/18/2022 == | == CRUNCH time before Rally!! 2/17/2022-2/18/2022 == | ||

[[File:Pit pic three.jpg|thumb|300x300px]] | |||

Rally is in three days! You know what that means? We have to finish this robot VERY soon so that we can give it to the programmers!! Today, we noticed that our intake wasn't level because the storage axle was not parallel to the ground. We had to shift one side of the storage down, but luckily we had prepared for this with our design and made each axle able to independently and efficiently shift downwards. We also riveted a thin piece of Lexan around the belts to protect the cargo when it passes through. We also replaced all of our 5mm belts with 9mm belts so that we have more control and rigidity over the axles. Intake is now officially done and ready for rally! | Rally is in three days! You know what that means? We have to finish this robot VERY soon so that we can give it to the programmers!! Today, we noticed that our intake wasn't level because the storage axle was not parallel to the ground. We had to shift one side of the storage down, but luckily we had prepared for this with our design and made each axle able to independently and efficiently shift downwards. We also riveted a thin piece of Lexan around the belts to protect the cargo when it passes through. We also replaced all of our 5mm belts with 9mm belts so that we have more control and rigidity over the axles. Intake is now officially done and ready for rally! | ||

| Line 65: | Line 66: | ||

== Piston Re-design == | == Piston Re-design == | ||

We went back to the drawing board to figure out an alternative piston mounting location that wouldn't impact our geometry too much. The problem was the pneumatic wiring, which was sticking out horizontally. We figured the best course of action would be to rotate the piston cylinder 90 degrees so that the wiring was facing down. However, our current piston mounting location made it difficult to do this, because our piston was attached through a bolt which gave it the ability to rotate vertically. This feature was critical to our entire intake design, so it was important to us to ensure that no matter how we changed the piston, we didn't loose that aspect. By giving the back piston mounting hole the ability to rotate, it allows us to attach the piston to a tail which is located past the intake pivot point. By having a larger lever arm, we are able to use less force to move the intake, which allows for us to use less air. Not to mention that if we change the specific point of the back pivot point, we would have to drill a new hole in the shooter side panel, which we really didn't want to do. After some brainstorming, we decided to use a larger clevis to clamp the top of the rear double acting piston. We drilled a hole in the side of it, so it just acts as an extension to our cylinder without having to buy an entirely new piston. | We went back to the drawing board to figure out an alternative piston mounting location that wouldn't impact our geometry too much. The problem was the pneumatic wiring, which was sticking out horizontally. We figured the best course of action would be to rotate the piston cylinder 90 degrees so that the wiring was facing down. However, our current piston mounting location made it difficult to do this, because our piston was attached through a bolt which gave it the ability to rotate vertically. This feature was critical to our entire intake design, so it was important to us to ensure that no matter how we changed the piston, we didn't loose that aspect. By giving the back piston mounting hole the ability to rotate, it allows us to attach the piston to a tail which is located past the intake pivot point. By having a larger lever arm, we are able to use less force to move the intake, which allows for us to use less air. Not to mention that if we change the specific point of the back pivot point, we would have to drill a new hole in the shooter side panel, which we really didn't want to do. After some brainstorming, we decided to use a larger clevis to clamp the top of the rear double acting piston. We drilled a hole in the side of it, so it just acts as an extension to our cylinder without having to buy an entirely new piston. This way, we only have to change the LOWER mounting location | ||

== New Lower Piston Mount == | |||

[[File:Pit Pic one.jpg|thumb|300x300px]] | |||

In order to find a new lower mounting location, we went back to the CAD model. First, we put the intake up so that it was inside frame perimeter. Then, we made a circle on the Lexan side plate that was the radius of our extended piston, including BOTH clevises, with the center point being our upper pivot point. Next, we put the intake down, so that our original circle moved with it. We then drew another circle that had a radius of the retracted piston. Where the two circles intersect are the two points where we could mount our piston without a slot. We adjusted the height of the intake off the ground to ensure that our stroke wasn't hitting our pulley, which we eventually moved inwards, out of the way. With our piston all figured out, we CNCed new side plates out of Lexan and tested. | |||

== Iteration two of Intake == | |||

[[File:Pit pic two.jpg|thumb|279x279px]] | |||

With each iteration of intake, we did 30 tests to flush out any issues. The new piston mount worked great, which would become a constant throughout our iterations. While doing testing, our team members make sure to only change one variable at a time in order to ensure that we can identify what is causing the issues. During testing, we noticed that the ball would get stuck between the first axle and the bumper and just kept spinning in place without moving up. After about an hour- an hour and a half of thorough investigation, we identified the problem: The axles were making contact on top of the ball, which inhibited the ball from moving up if the ball came in the intake with side spin. In order to solve this, we discovered that we had to move the first axle forward, so it grabbed around the ball. We tested this by clamping small metal bars with bearing holes to the edge of the intake and running the axle with a drill through it. Once we had it so that it worked 30 times, we took measurements of the axle placement and redesigned it. | |||

== Iteration three of Intake == | |||

For this version of the intake blades, we decided to CNC it out of scrap half inch wood. Wood takes significantly less time to CNC and is a lot cheaper, so using it for prototyping maximized efficiency for our team. We extended the first axle 1.5 inches in a straight line coming off of our current geometry. Once we began testing, we noticed that although our problems were solved, some new ones arose. For example, now that there was a bigger gap, a ball could fit in between the two axles and get jammed, In order to prevent this, we designed a notch that stems off in between the two axles that we will attach a Lexan strip to. The Lexan will stop the balls from popping up and keep them in line with their planned trajectory. We also noticed that because the intake blades are technically longer, we are again outside of frame perimeter. After some brainstorming, we decided to keep all of our mounting locations and the original piston, and just change the length of the clevis to simulate a longer stroke length. This meant we had to design our own clevis. We decided to make it out of scrap pieces of axles from previous years. We cut them to the right length, and then tapped them farther than we needed to give us room to adjust our stroke length. | |||

== Iteration four of intake == | |||

We took the the CNC machine once again to CNC new side blades. We added all of the updates changes and then implemented them on our robot. Finally, we tested it for two days, running normal drive practice and letting programmers mess around with it. After we were confident that we solved all of our problems, we CNCed the final plates out of Lexan. The only difference with the final version (iteration five) is that it has rivet holes for the belt guards and to rivet the sides together. The final blades came out great, and our hard work finally paid off! | |||

Latest revision as of 02:40, 10 March 2022

Leaders: Nick V. and Kadence O.

Prototyping 1/9/2022-1/12/2022

Right after kickoff, we divided into groups and started brainstorming intake ideas. We looked over all of our ideas and found the common denominators between all of the designs; over the bumper intake designs and using wheels (either single axil or double axil). Since we decided on a swerve we drive base, we knew that cutting into the bumper would force us to compromise overall stability- something our strategy team determined was very important. We thought that a double axil could help guide the ball to storage and it might be beneficial in getting it over our 6" (off the ground) bumper. Next, tested each wheels impact on the cargo and discovered that compliance wheels worked the best. Finally, we launched into prototyping and set up a to-scale drive base with a bumper for reference. We prototyped both 4" and 2" compliance wheels of different densities and decided on 2" black compliance wheels and then made sketches and a 3D CAD model to help us determine the height of the intake.

Prototyping 1/13/2022

Today, we picked up where we left off and went back to the CAD drawing, adjusting angles and measurements as we learned more information. After finding out that 9.125" from the ground to the center of the axil and 10.625" from the inside of the bumper to the center of the axil, we began to create more accurate dimensions based on our strategy teams long/skinny robot goal. We estimated that the front of our robot would be roughly 22" (not including bumper), so we reduced the intake to 16" and tested it. Once we got that working, we worked very closely with the storage team and integrated our ideas together, working on a way to transfer the cargo from intake to storage. we decided on a funnel, made from a Lexan-like plastic and began prototyping. We are still trying to get the right angle/arc for the funnel.

Prototyping 1/15/2022

Picking up where we left off, we integrated the storage mechanism into the intake using a second axle with 2"compliance wheels to transition the cargo, 14.5" from the ground to the center of axle and 4" from the inner bumper to the center of axle. We also attached Lexan near the first axle in order to keep the ball low and control the parabola oriented arc. Next, we stabilized the intake mechanisms at the correct lengths and orientations relevant to the storage, and tested the intake, picking up the ball from multiple angles and positions. All of our tests were done while the robot was moving, rather than feeding into the robot, to give us more accurate results.

Prototyping 1/16/2022

Today, we decided to integrate the intake, storage, and shooter mechanisms in order to make sure the systems fit together. First, we needed to do a rough robot real-estate, so that we could determine the sizes of our mechanism. Through CAD/Inventor testing, we found that the mechanisms were able to work together well with a intake width of 16" (outside to outside). Next, we determined belt width and tooth sizes for our intake pulleys and put them in the team shopping cart. The rest of the day was spent doing shooter to storage integration.

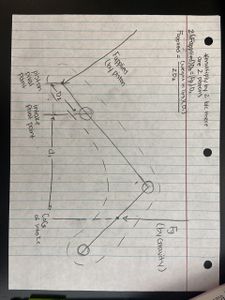

CAD 1/19/2022

After a team integration to get everyone on the same page, cargo joined as a group to assemble our prototypes in CAD in order to figure out how to retract intake and what angle storage/shooter will be in order to maximize space efficiency. We each made separate assemblies for each mechanism and then placed them in a drive base assembly. Once the intake, storage, and shooter were all in one assembly, we were able to properly constrain and align the mechanisms to what we believe is the most beneficial positions. By placing the storage 48.82 degrees from the top of the drive base and by setting the intake pivot point to the top of the storage, we were able to retract the intake into the frame perimeter. Tomorrow, we will try to assemble this complete cargo pathway using the tools in our shop and see if all of our dimensions are still accurate.

Testing 1/20/2022

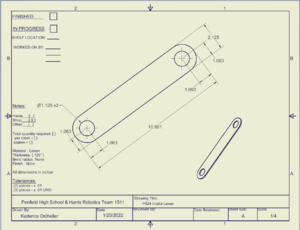

After making a shop drawings for the intake to get dimensions, we began to build our current CAD model in the shop. We cut out four pieces of 2.125"x10.801" Lexan to use as our side panels. After that, we remounted the axles on the Lexan and made a tensioner for the belts on the intake.

CAD/Testing 1/22/2022

First thing this morning, our storage and intake teams worked on modelling our prototype after our new CAD module. After making adjustments (shifting the storage axles closer together, securing the angle of the intake pieces, belting the storage and intake together, etc), we were able to get a consistent and successful cargo path into the hypothetical shooter (shooter was not attached to our cargo pathway prototype)! At the same time, we had more cargo members working on CAD and calculations. We created a new CAD model in Inventor with more accurate pieces, materials, and dimensions, taking the hang space needs into high consideration. We used the information we had to start to do piston calculations. In order to determine the length of our stroke and the bore, we had to find the center of gravity and the torque using an excel spreadsheet and formulas. We used the necessary PSI (50 lbs/in^2) to find the force we needed to apply by the piston and plan to pick up where we left off tomorrow.

CAD 1/23/2022

Today we continued piston calculations. Through examining the length we needed the stroke to travel and the rotation of the Lexan Intake arm, we were able to determine that the most ideal piston for our intake would be a piston with a diameter of .75" and a stroke length of five inches. This allows for us to have a decent safety net in terms of force and angle distance. Then, we did a motor analysis based on our desired velocity and were able to determine that ideally we want a 4 to 1 ratio. Then, we made a CAD model and used that to determine final critical dimensions.

CAD! 1/26/2022

First thing today, we jumped right into CAD! By calculating belt sizes and putting on mock-up belts, we were able to make our CAD model more detailed and accurate. The belts we were looking at were placed 8.67 inches apart from center of axle to center of axle. From there, we determined that a tensioner of some sort would be necessary, so we worked on making adjustment holes for the tensioners. Prior to tonight, we had two quarter inch Lexan panels on each side, making it a total of .5 inches of Lexan per side for extra protection and rigor. However, because of our extensive intake pulley system (in which we have three different belts on the intake alone), we decided that we should separate two of the Lexan on one side, so that there is a quarter inch of protection on each side of our belts. We ended by modeling our CAD assembly to match our Lexan idea and making minor adjustments to the CAD.

CAD 1/29/2022

Today we re-measured the lengths of intake because it was interfering in the allotted space for hang. The length of the axle changed from being a little over 20 inches from the outside of the lexan pieces to being 16.5 inches from outside to outside. We then moved the middle pully of the three that were on the left side (from the front view) of intake to the right side. After this we condensed the spacers to being smaller sizes, which allowed for the length of the axle to be smaller. We also removed some of the lock and collars because they were no longer needed, and any places that had a big enough space we put a 0.79 inch spacer. The updated version of intake has been placed and constrained in the Final Robot Assembly, and there is a separate assembly named Final Robot Assembly- Update Axle where we were originally working on updating the lengths of the axle. Then, we switched gears to work on pistons. We made a CAD assembly for the pistons, complete with mounting brackets. We made mounting holes for the pistons and mounted them to the storage/shooter area, ensuring that it did not interfere with the hang or the infrastructure. We then made a slot in the intake, where the piston is going to mount, because we found that when the piston rotates and extends, one of the sides needs to slightly move vertically as well.

CAD Weekend (Part 2) 1/30/2022

With Piston mountings finalized, we were able to order the correct pistons and get those assemblies finalized in CAD. Next, we mounted our tensioners for our intake belts and cleaned up the CAD. Finishing the night, we began making shop drawings for our finalized parts so we could send them off to our main sponsor, L3Harris.

CAD. 2/1/2022

Today, we looked over our final intake CAD and discovered that the tensioner holes were too small for the shoulder bolts that we were using. We widened the holes and made a shop drawing so that we can get our Lexan CNC and get to building!! We continued to work on shop drawings and did robot weight calculations!

CAD/Shop Drawings 2/2/2022

With our intake CAD finalized, we were able to shift our time and resources towards our subteams that needed more hands, so there was not a lot of intake/storage work done today. However, when we finalized shooter, we were able to get a more proportional/realistic portrayal of our robot, and discovered a potential problem. It appeared as though when the intake was inside the robot, it might interfere with the trajectory of our long shot! Luckily, we gave ourselves some wiggle room when designing the intake and brought the intake into the robot farther than we had to. This is beneficial because, if our intake does interfere with shooter, than we can easily move the intake forward the extra space and hope that that is enough to avoid conflict. Since our intake is controlled with pistons, this should be an easy fix. We noticed this inconsistency at the end of our meeting, so we did not have time to further investigate. We will pick up where we left off tomorrow!

CAD/Shop Drawings 2/5/2022

We determined today that our shooter does not interfere with our intake!! After we re-constrained the drive base, we realized that our storage Lexan and our storage axles were not parallel, so once we fixed it the shooter moved out of the way. We also mounted our pistons in the final robot assembly. Finally, we noticed that the locking collars in our assemblies were not the right size!!! This threw off our axle length, so we fixed all of the parts!

Finishing CAD!! 2/6/2022

In order to make our shot against the hub, we had to modify our shooter plate/Lexan side panel. This caused our pneumatic cylinders to interfere with the shooter Lexan. Luckily, since we have already done the calculations before, we knew that whatever piston we used, the amount of force applied by both pistons times the length of our piston pivot point to our intake pivot point had to be at least 63 lbs (we got this number by multiplying the weight of our intake which is approximately seven lbs by the distance from our pivot point to our center of gravity which was approximately 9 inches). Using this method and the pistons we readily have available, we were able to make a 4 inch stroke length work for our intake, which shifted the piston mounting down, making room for the shooter. We also made the original piston work by creating a new mounting hole and a new slot, lower down in the Lexan. This would be our last resort since we would have to drill mounting holes in our shooter side plate, which has already been sent off to L3Harris. By doing this, we now have options in case something changes and we need more force. We also added riveting holes to the intake Lexan so that we can add a protective Lexan cover for our belts. This is going to prevent balls from hitting the belts and more importantly, help protect our students, drive team, and Pit crew who may be reaching in not realizing that there are moving belts, Although we are very cautious and always ensure that no one is touching the robot when there are parts moving, this extra measure will help everyone feel more safe and at ease. As of today, our intake CAD is complete!! From now on, we will be focusing on shop drawings, which are mostly done, and then on fabricating parts!!!

Fabrication! 2/8/2022

Today, we began fabrication! With our CAD and most of our shop drawings done, we started to make the parts. The first step was to make the intake Lexan plates. In order to test that our scale was correct and that everything was working according to plan, we made a side plate profile on a scrape piece of wood. After verifying that that was what we wanted, we cut out a 24" x 10" Lexan piece, and took it to the CNC. Although we made the correct profile on the Lexan, we found that the CNC was on too low of a setting, which caused issues around the edges and rivet holes. We are planning on trying again with a higher setting to get more precise and accurate cuts.

Fabrication!!!! 2/11/2022- 2/12/2022

We made our intake assembly!! over the past two days, we FINISHED fabrication for intake, making the entire assembly. We mounted the pistons but still need to hook them up and attach them to the intake. We also have the intake assembly as a separate unit right now and are planning on attaching them tomorrow. We have also discovered that our piston mounting MIGHT interfere with our hangar's pistons. We decided to keep it simple, and move on with our original mounting. If we end up having to change it, we will just rotate it up on it's axle so that we won't have to change the mounting holes.

Mounting! 2/13/2022

We finally mounted the intake, and everything lined up! We had a little bit of sag because of the slots, so we added little .25" Lexan pieces in order to keep the ends of the piston from slipping. This fixed our sag, but then we had a piston conflict which was quickly resolved. Everything looks to be fitting great, and we do plan on re-CNCing the intake side plates so that the slot is no longer there.

CRUNCH time before Rally!! 2/17/2022-2/18/2022

Rally is in three days! You know what that means? We have to finish this robot VERY soon so that we can give it to the programmers!! Today, we noticed that our intake wasn't level because the storage axle was not parallel to the ground. We had to shift one side of the storage down, but luckily we had prepared for this with our design and made each axle able to independently and efficiently shift downwards. We also riveted a thin piece of Lexan around the belts to protect the cargo when it passes through. We also replaced all of our 5mm belts with 9mm belts so that we have more control and rigidity over the axles. Intake is now officially done and ready for rally!

Post Rally Intake Evaluation

We had noticed that the intake had a few significant problems after Rally, our week zero scrimmage. 1) the piston holes were extremely unstable since they were being temporarily held at the bottom of a slot with an additional piece of Lexan. Because these slots were hand made, they were consistent on each side which caused them to be uneven. 2) Additionally, the stroke of the piston was interfering with the spacers. Although this wasn't the end of the world, eventually it could lead to our strokes bending, which would not be good.

After Rally, are biggest concern became our interference with our hangar mechanism. Although our pistons are out of hangar space, we forgot to account for the pneumatic wiring in this said space. So even though our cylinders don't interfere with hangar, our wires interfere with their pistons. Since our pistons are easier to adjust than theirs, we agreed to move our pistons.

Piston Re-design

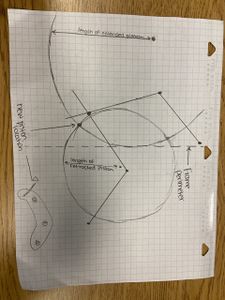

We went back to the drawing board to figure out an alternative piston mounting location that wouldn't impact our geometry too much. The problem was the pneumatic wiring, which was sticking out horizontally. We figured the best course of action would be to rotate the piston cylinder 90 degrees so that the wiring was facing down. However, our current piston mounting location made it difficult to do this, because our piston was attached through a bolt which gave it the ability to rotate vertically. This feature was critical to our entire intake design, so it was important to us to ensure that no matter how we changed the piston, we didn't loose that aspect. By giving the back piston mounting hole the ability to rotate, it allows us to attach the piston to a tail which is located past the intake pivot point. By having a larger lever arm, we are able to use less force to move the intake, which allows for us to use less air. Not to mention that if we change the specific point of the back pivot point, we would have to drill a new hole in the shooter side panel, which we really didn't want to do. After some brainstorming, we decided to use a larger clevis to clamp the top of the rear double acting piston. We drilled a hole in the side of it, so it just acts as an extension to our cylinder without having to buy an entirely new piston. This way, we only have to change the LOWER mounting location

New Lower Piston Mount

In order to find a new lower mounting location, we went back to the CAD model. First, we put the intake up so that it was inside frame perimeter. Then, we made a circle on the Lexan side plate that was the radius of our extended piston, including BOTH clevises, with the center point being our upper pivot point. Next, we put the intake down, so that our original circle moved with it. We then drew another circle that had a radius of the retracted piston. Where the two circles intersect are the two points where we could mount our piston without a slot. We adjusted the height of the intake off the ground to ensure that our stroke wasn't hitting our pulley, which we eventually moved inwards, out of the way. With our piston all figured out, we CNCed new side plates out of Lexan and tested.

Iteration two of Intake

With each iteration of intake, we did 30 tests to flush out any issues. The new piston mount worked great, which would become a constant throughout our iterations. While doing testing, our team members make sure to only change one variable at a time in order to ensure that we can identify what is causing the issues. During testing, we noticed that the ball would get stuck between the first axle and the bumper and just kept spinning in place without moving up. After about an hour- an hour and a half of thorough investigation, we identified the problem: The axles were making contact on top of the ball, which inhibited the ball from moving up if the ball came in the intake with side spin. In order to solve this, we discovered that we had to move the first axle forward, so it grabbed around the ball. We tested this by clamping small metal bars with bearing holes to the edge of the intake and running the axle with a drill through it. Once we had it so that it worked 30 times, we took measurements of the axle placement and redesigned it.

Iteration three of Intake

For this version of the intake blades, we decided to CNC it out of scrap half inch wood. Wood takes significantly less time to CNC and is a lot cheaper, so using it for prototyping maximized efficiency for our team. We extended the first axle 1.5 inches in a straight line coming off of our current geometry. Once we began testing, we noticed that although our problems were solved, some new ones arose. For example, now that there was a bigger gap, a ball could fit in between the two axles and get jammed, In order to prevent this, we designed a notch that stems off in between the two axles that we will attach a Lexan strip to. The Lexan will stop the balls from popping up and keep them in line with their planned trajectory. We also noticed that because the intake blades are technically longer, we are again outside of frame perimeter. After some brainstorming, we decided to keep all of our mounting locations and the original piston, and just change the length of the clevis to simulate a longer stroke length. This meant we had to design our own clevis. We decided to make it out of scrap pieces of axles from previous years. We cut them to the right length, and then tapped them farther than we needed to give us room to adjust our stroke length.

Iteration four of intake

We took the the CNC machine once again to CNC new side blades. We added all of the updates changes and then implemented them on our robot. Finally, we tested it for two days, running normal drive practice and letting programmers mess around with it. After we were confident that we solved all of our problems, we CNCed the final plates out of Lexan. The only difference with the final version (iteration five) is that it has rivet holes for the belt guards and to rivet the sides together. The final blades came out great, and our hard work finally paid off!