2025:Cage: Difference between revisions

Mechanical1 (talk | contribs) No edit summary |

Mechanical1 (talk | contribs) No edit summary |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

1/16/2025 | '''<span style="font-size: 18pt;" >1/16/2025 :</span>''' | ||

<p>Finished prototyping on all considered designs. We have decided to disregard the "Bicep Hang" design as it is difficult to implement due to the fact that it causes issues with balancing, and because it would be difficult to stop it from contacting the "Anchor" of the cage. We are moving forward, beginning with CAD designs of the "Double Lever Hang" design because it has the best center of gravity for the hang, and it is relatively simple to implement on the robot, not taking up much space.</p> | <p>Finished prototyping on all considered designs. We have decided to disregard the "Bicep Hang" design as it is difficult to implement due to the fact that it causes issues with balancing, and because it would be difficult to stop it from contacting the "Anchor" of the cage. We are moving forward, beginning with CAD designs of the "Double Lever Hang" design because it has the best center of gravity for the hang, and it is relatively simple to implement on the robot, not taking up much space.</p> | ||

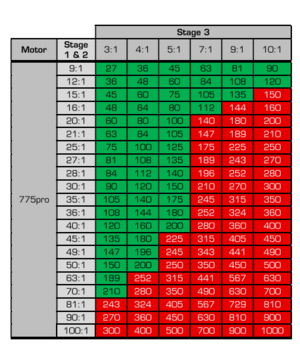

*Selected potential gearbox and motors for hang designs | *Selected potential gearbox and motors for hang designs | ||

| Line 103: | Line 103: | ||

[[image:img1737588881144.png|thumb|300px]] | [[image:img1737588881144.png|thumb|300px]] | ||

1/21/2025 - CAD: | '''<span style="font-size: 18pt;" >1/21/2025 - CAD:</span>''' | ||

*Discussed with other Subteams about spacing, battery placement, and frame size. | *Discussed with other Subteams about spacing, battery placement, and frame size. | ||

*Moving to alternative designs due to battery placement. | *Moving to alternative designs due to battery placement. | ||

| Line 217: | Line 217: | ||

*<span style="font-size: 12pt;">Finalize design for production</span> | *<span style="font-size: 12pt;">Finalize design for production</span> | ||

*<span style="font-size: 12pt;">Add brackets and hard wear for mounting </span> | *<span style="font-size: 12pt;">Add brackets and hard wear for mounting </span> | ||

<span style="font-size: 12pt;"></span> | |||

'''<span style="font-size: 18pt;">12/29/2025 - CAD and SHOP <span style="font-size: 12pt;"><span style="font-size: 18pt;" >DRAWINGS</span>:</span></span>''' | |||

*<span style="font-size: 12pt;">Worked on making shop drawings for parts and sending them out</span> | |||

*<span style="font-size: 12pt;">Finalized the Ratchet and Pawl mechanism </span><span style="font-size: 12pt;"></span> | |||

*<span style="font-size: 12pt;">Made mounting plates for the bar used to mount the ratchet and pawl mechanism</span> | |||

<span style="font-size: 12pt;">TO DO: </span> | |||

*<span style="font-size: 12pt;">Continue making shop drawings for parts</span> | |||

*<span style="font-size: 12pt;">Add the mounting brackets and hard wear for mounting</span> | |||

<span style="font-size: 12pt;"></span> | |||

<span style="font-size: 12pt;"></span> | |||

<span style="font-size: 12pt;"></span> | |||

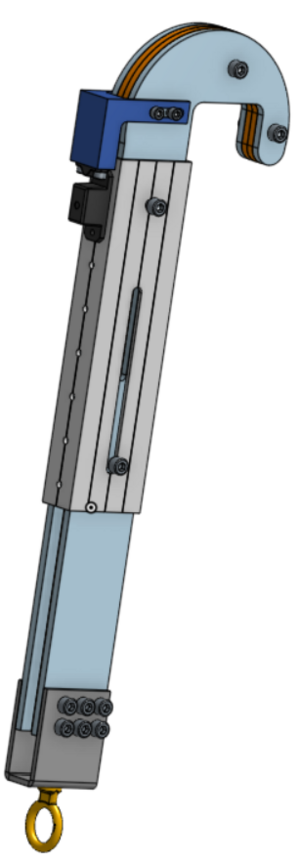

'''<span style="font-size: 18pt;">02/01/2025 - SHOP DRAWINGS and CAD:</span>'''[[image:img1738631448514.png|thumb|300px]] | |||

'''''' | |||

*<span style="font-size: 12pt;">Worked on shop drawings </span> | |||

*<span style="font-size: 12pt;">Worked on 3D printing the mounting block for the solenoid and 3D printing other hang parts</span> | |||

*<span style="font-size: 12pt;">Figured out flag sensor for detecting when the solenoid is engaged or not</span> | |||

*<span style="font-size: 16px;">Added the mounting brackets and hard wear for mounting</span> | |||

<span style="font-size: 12pt;">TO DO:</span> | |||

*<span style="font-size: 12pt;">Continue making shop drawings for parts </span> | |||

*<span style="font-size: 12pt;">Start machining and creating parts for hang</span> | |||

*<span style="font-size: 12pt;">Start assembling the hang mechanisms</span> | |||

<span style="font-size: 12pt;"></span> | <span style="font-size: 12pt;"></span> | ||

'''<span style="font-size: 18pt;" > | <span style="font-size: 12pt;"></span> | ||

*<span style="font-size: 12pt;" >Worked on making shop drawings for parts | |||

*<span style="font-size: 12pt;" >Finalized the | <span style="font-size: 12pt;"></span> | ||

*<span style="font-size: 12pt;" > | |||

<span style="font-size: 12pt;" >TO DO: </span> | '''<span style="font-size: 18pt;">02/02/2025 - MACHINING and SHOP DRAWINGS:</span>''' | ||

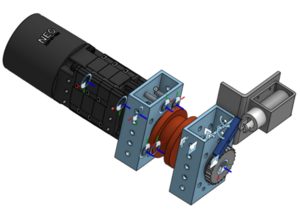

*<span style="font-size: 12pt;" > | *<span style="font-size: 12pt;">Worked on machining and creating the ratchet and pawl mounting bars</span> | ||

*<span style="font-size: 12pt;" > | *<span style="font-size: 12pt;">Worked on painting the mounting bars[[image:img1738575487921.png|thumb|300px]]</span> | ||

*<span style="font-size: 12pt;">Worked on starting to assemble the solenoid with the 3D printed mounting brick</span> | |||

*<span style="font-size: 12pt;">Worked on making more shop drawings</span> | |||

TO DO: | |||

*Continue assembling the shallow hang mechanism | |||

*Continue manufacturing parts for assembly | |||

*Start discussing with RCS about controls and programing | |||

'''<span style="font-size: 18pt;">02/04/2025 - CAD AND SHOP DRAWINGS:</span>''' | |||

*<span style="font-size: 12pt;">Made shop drawings for parts</span> | |||

*<span style="font-size: 12pt;">Finalized the location for the frame mounting bar that hold the ratchet and pawl mechanism in place</span> | |||

*<span style="font-size: 12pt;">Decided on shallow hang - look into possibly doing deep hang later</span><span style="font-size: 12pt;"></span> | |||

<span style="font-size: 12pt;">TO DO:</span> | |||

*<span style="font-size: 12pt;">Continue manufacturing and fabricating parts</span> | |||

*<span style="font-size: 12pt;">Assemble the shallow hook hang mechanism</span> | |||

*<span style="font-size: 12pt;">Finish all shop drawings</span> | |||

*<span style="font-size: 12pt;">Start discussions with RCS about controls and programming of mechanisms</span> | |||

*<span style="font-size: 12pt;">Create a pulley to guide the strip to the wheel</span> | |||

*Finalized the hook part for the shallow hang<span style="font-size: 12pt;"></span> | |||

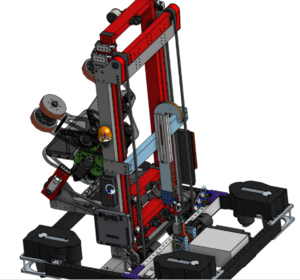

'''<span style="font-size: 18pt;" >02/05/2025 - CAD and MANUFACTURING:</span>''' | |||

*<span style="font-size: 12pt;" >Worked on the hook for the shallow hang </span> | |||

*<span style="font-size: 12pt;" >Worked on manufacturing and making the hex shaft for the ratchet and pawl mechanism on the lathe</span> | |||

*<span style="font-size: 12pt;" >Worked on manufacturing other parts </span> | |||

<span style="font-size: 12pt;" >TO DO:</span> | |||

*<span style="font-size: 12pt;" >Continue manufacturing and fabricating parts</span> | |||

*<span style="font-size: 12pt;" >Continue assembly on ratchet and pawl mechanism </span> | |||

*<span style="font-size: 12pt;" >Finalize the hook for the shallow hook hang before starting assembly of it</span> | |||

*<span style="font-size: 12pt;" >Create a pulley to guide the strip to the wheel</span> | |||

*<span style="font-size: 12pt;" >Finalize all shop drawings for manufacturing</span><span style="font-size: 12pt;" ></span> | |||

*<span style="font-size: 12pt;" >Build a transmission for the winch mechanism</span> | |||

*<span style="font-size: 12pt;" >Change the colors of the CAD parts to black and red - for matching what are moving and non-moving parts[[image:img1738815131418.png|thumb|300px]]</span> | |||

Latest revision as of 17:52, 5 February 2025

1/16/2025 :

Finished prototyping on all considered designs. We have decided to disregard the "Bicep Hang" design as it is difficult to implement due to the fact that it causes issues with balancing, and because it would be difficult to stop it from contacting the "Anchor" of the cage. We are moving forward, beginning with CAD designs of the "Double Lever Hang" design because it has the best center of gravity for the hang, and it is relatively simple to implement on the robot, not taking up much space.

- Selected potential gearbox and motors for hang designs

1/18/2025 - CAD:

- Came up with ideas for stop mechanism (Ratchet and Pawl mechanism.)

- Worked on an idea for outward moving riggers to keep the robot balanced during hang.

- Worked on a CAD model for the double lever hang, including custom made lifter arms.

TO DO:

- Work with Drive Base and Game piece to finalize drive base dimensions

- Continue CAD design

- Work on the Ratchet Mechanism in CAD

- Figure out where the battery will be placed on the robot

- CAD design for the funnel/game piece guider

1/19/2025 - CAD:

- Worked on CAD model for the ratchet and pawl mechanism and attempted to integrate it into the double lever hang design

- Lengthened the hex shafts on the CAD model to add another lever on both sides of the lever hang

- Mounting pieces for the motor were created and attached

- Troubles with integrating the ratchet and pawl mechanism became apparent due to lack of space

TO DO:

- Figure out how to orient the ratchet in order to accomplish a working relationship between both the ratchet and pawl mechanism, and the double lever hang mechanism

- Continue refining CAD designs for the mechanisms

- Check in with Game piece sub-team

- Have a conversation with electrical about the placement of the battery

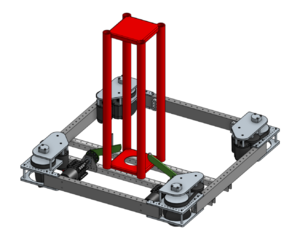

1/21/2025 - CAD:

- Discussed with other Subteams about spacing, battery placement, and frame size.

- Moving to alternative designs due to battery placement.

- Targeting Shallow Cage instead of Deep Cage.

- Designing single, moving hook mechanism, mounted on elevator crossbar and driven with a winch.

- Possibly using existing designs:

To Do:

- Continue Shallow Cage climb design.

- Explore potential Deep Cage designs that work with rear battery placement.

1/23/2025 - CAD:

- Worked on creating a sliding hook mechanism to attach onto the (in progress) Shallow Hang Mechanism

- Worked on creating a new ratchet and pawl mechanism for the Shallow Hang Mechanism

- Worked on creating new motor mounts and orientation of the mechanism in CAD

TO DO:

- Continue to work on Shallow Cage climb design

- Create an assembly for the Shallow Cage Winch Hang

- Create a prototype off of the assembly

- Test the prototype

- Research and create new deep cage climbing mechanisms that will cooperate with the new found battery placement in the rear end of the robot.

1/25/2025 - CAD:

- Worked on assembling and configuring the new ratchet and pawl mechanism

- Worked on creating and assembling the hook for the the shallow hook hang mechanism

- Worked on assembling and integrating the two mechanisms into the final robot

TO DO:

- Finalize ratchet and pawl mechanism

- Finalize the mounting of the mechanisms to the robot

- Update the geometry of the hook to make it more realistic and working

- Approve parts for drawings and manufacturing

12/26/2025 - CAD:

- Worked on a re-location of the solenoid on the ratchet mechanism

- Insert the assembly in the final robot assembly

TO DO:

- Add fasteners and mounting to the solenoid assembly

- Create and add mounting brackets to connect the winch mount bar to the drive base

- Prepare the design for productions and start shop drawings

12/28/2025 - CAD and SHOP DRAWINGS:

- Hang ratchet gear was finalized and sent out as a shop drawing

- Worked on finalizing ratchet and pawl mechanism - Almost complete

- Worked on making shop drawings for parts

TO DO:

- Finalize design for production

- Add brackets and hard wear for mounting

12/29/2025 - CAD and SHOP DRAWINGS:

- Worked on making shop drawings for parts and sending them out

- Finalized the Ratchet and Pawl mechanism

- Made mounting plates for the bar used to mount the ratchet and pawl mechanism

TO DO:

- Continue making shop drawings for parts

- Add the mounting brackets and hard wear for mounting

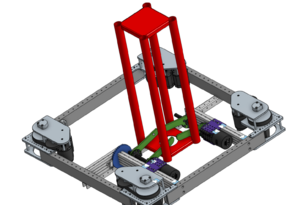

02/01/2025 - SHOP DRAWINGS and CAD:

'

- Worked on shop drawings

- Worked on 3D printing the mounting block for the solenoid and 3D printing other hang parts

- Figured out flag sensor for detecting when the solenoid is engaged or not

- Added the mounting brackets and hard wear for mounting

TO DO:

- Continue making shop drawings for parts

- Start machining and creating parts for hang

- Start assembling the hang mechanisms

02/02/2025 - MACHINING and SHOP DRAWINGS:

- Worked on machining and creating the ratchet and pawl mounting bars

- Worked on painting the mounting bars

- Worked on starting to assemble the solenoid with the 3D printed mounting brick

- Worked on making more shop drawings

TO DO:

- Continue assembling the shallow hang mechanism

- Continue manufacturing parts for assembly

- Start discussing with RCS about controls and programing

02/04/2025 - CAD AND SHOP DRAWINGS:

- Made shop drawings for parts

- Finalized the location for the frame mounting bar that hold the ratchet and pawl mechanism in place

- Decided on shallow hang - look into possibly doing deep hang later

TO DO:

- Continue manufacturing and fabricating parts

- Assemble the shallow hook hang mechanism

- Finish all shop drawings

- Start discussions with RCS about controls and programming of mechanisms

- Create a pulley to guide the strip to the wheel

- Finalized the hook part for the shallow hang

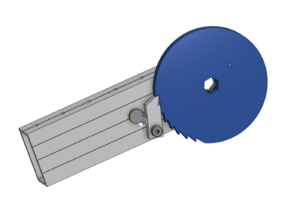

02/05/2025 - CAD and MANUFACTURING:

- Worked on the hook for the shallow hang

- Worked on manufacturing and making the hex shaft for the ratchet and pawl mechanism on the lathe

- Worked on manufacturing other parts

TO DO:

- Continue manufacturing and fabricating parts

- Continue assembly on ratchet and pawl mechanism

- Finalize the hook for the shallow hook hang before starting assembly of it

- Create a pulley to guide the strip to the wheel

- Finalize all shop drawings for manufacturing

- Build a transmission for the winch mechanism

- Change the colors of the CAD parts to black and red - for matching what are moving and non-moving parts