Mechanical: Difference between revisions

Mechanical1 (talk | contribs) No edit summary |

Mechanical1 (talk | contribs) No edit summary |

||

| Line 5: | Line 5: | ||

Mach. 1511 team: ( Mike M., Kristina Kohl, Jacob Kremer) we marked the holes for the screws to reattach the drive train to the frame. We also brainstormed ideas fo reparing rofflebot. Next week we will drill out the iron bar and will finish up repairs on Mach. | Mach. 1511 team: ( Mike M., Kristina Kohl, Jacob Kremer) we marked the holes for the screws to reattach the drive train to the frame. We also brainstormed ideas fo reparing rofflebot. Next week we will drill out the iron bar and will finish up repairs on Mach. | ||

<br> | <br> | ||

Inventor group: | Inventor group: | ||

| Line 11: | Line 11: | ||

Sam L, Alex R and Chris H completed lessons 1 and 2 for inventor. We watched Alex W make a chain tensioner on Inventor. Alex explained the benefeits of using Inventor in the process. We then reviewed a prototype of the tensioner for how it would function on Mach 1511. Then we revised the model to reflect our findings. | Sam L, Alex R and Chris H completed lessons 1 and 2 for inventor. We watched Alex W make a chain tensioner on Inventor. Alex explained the benefeits of using Inventor in the process. We then reviewed a prototype of the tensioner for how it would function on Mach 1511. Then we revised the model to reflect our findings. | ||

<br> | <br> | ||

ThunderPlucker: | ThunderPlucker: | ||

| Line 17: | Line 17: | ||

Tony, Liz, Tresten, Shauna, Mike Hartman fixed the top spinner on Thunder Plucker and moved the motor. Replaced the missing or broken pluckers on the bottom roller. Moved belts back to where they belong (again...). "i think thats pretty much it..." -Tony | Tony, Liz, Tresten, Shauna, Mike Hartman fixed the top spinner on Thunder Plucker and moved the motor. Replaced the missing or broken pluckers on the bottom roller. Moved belts back to where they belong (again...). "i think thats pretty much it..." -Tony | ||

<br> | <br> | ||

Robot Locations: | Robot Locations: | ||

| Line 29: | Line 29: | ||

Trailer Key is in the closet. | Trailer Key is in the closet. | ||

<br> | <br> | ||

11/4/2009 | 11/4/2009 | ||

| Line 35: | Line 35: | ||

We went over the eight steps to the engineering process. | We went over the eight steps to the engineering process. | ||

Mach. 1511: - (Group 2) Mike M., Becca and Jake Kremer, Shauna ~Mach. was at a demo, we worked on ROFl Bot, came up with a plan to fix the ball pen and to fix the panels. We used the NASAs engineering design sheet to plan out what we needed to do to fix Rofl Bot. We defined a problem: THe Ball pen is broken becauser it has no net and it is floppy and looks like @#$%. We then defined constraints, we want to keep the weight as low as possibvle and keep everything within the robot dimentions. We made several sketches on the SMART board and are saved under a smart doc. I will put them on when I figure out how to. We already started the prototype phase, we used 30lb. test fishing line in place of metal wire. It was ridgid enough to continue on with that design. <br> | Mach. 1511: - (Group 2) Mike M., Becca and Jake Kremer, Shauna ~Mach. was at a demo, we worked on ROFl Bot, came up with a plan to fix the ball pen and to fix the panels. We used the NASAs engineering design sheet to plan out what we needed to do to fix Rofl Bot. We defined a problem: THe Ball pen is broken becauser it has no net and it is floppy and looks like @#$%. We then defined constraints, we want to keep the weight as low as possibvle and keep everything within the robot dimentions. We made several sketches on the SMART board and are saved under a smart doc. I will put them on when I figure out how to. We already started the prototype phase, we used 30lb. test fishing line in place of metal wire. It was ridgid enough to continue on with that design. <br> | ||

Goals: | Goals: | ||

| Line 49: | Line 49: | ||

R ~contact electrical subteam to see if we have conflicting ideas | R ~contact electrical subteam to see if we have conflicting ideas | ||

<br> | <br> | ||

thunder plucker:- Tony B, Lizzy M. find probloms that still exists and fix them. | thunder plucker:- Tony B, Lizzy M. find probloms that still exists and fix them. | ||

<br> | <br> | ||

Inventor team | Inventor team | ||

| Line 65: | Line 65: | ||

2. Finish chain tensioner | 2. Finish chain tensioner | ||

<br> | <br> | ||

Robot Locations: | Robot Locations: | ||

<br> | <br> | ||

<br> | <br> | ||

Mach.~ Trailor | Mach.~ Trailor | ||

| Line 79: | Line 79: | ||

ROFL Both~ A-10 | ROFL Both~ A-10 | ||

<br> | <br> | ||

'''Leanne Attendence:''' Alex W., Sam L., Alex R., Chris H., Tony B., Lizzy M,.Mike M., Becca, Jake K., Shaunah, Mr. and Mrs. Wolf | '''Leanne Attendence:''' Alex W., Sam L., Alex R., Chris H., Tony B., Lizzy M,.Mike M., Becca, Jake K., Shaunah, Mr. and Mrs. Wolf | ||

<br> | <br> | ||

11/18/09 | 11/18/09 | ||

| Line 95: | Line 95: | ||

4. We discussed measurements (callipers). | 4. We discussed measurements (callipers). | ||

<br> | <br> | ||

'''ROFLBot :''' Liz M. , Ben S. Nathan K. | '''ROFLBot :''' Liz M. , Ben S. Nathan K. | ||

| Line 101: | Line 101: | ||

11/18/09 | 11/18/09 | ||

<br> | <br> | ||

1. We brainstormed ideas to fix the basket following the design process and learned about free body diagrams | 1. We brainstormed ideas to fix the basket following the design process and learned about free body diagrams | ||

2. We looked up cables and ropes on McMaster Carr for material selection considering constraints<br> | 2. We looked up cables and ropes on McMaster Carr for material selection considering constraints<br> | ||

<br> | <br> | ||

<br> | <br> | ||

Inventor team- Shauna, Alex, Becca, Jake | Inventor team- Shauna, Alex, Becca, Jake | ||

| Line 115: | Line 115: | ||

Completed lessons 1-3 and the unwritten lesson 4<br>Did random enrichment that Alex found on a desk called 2D quiz | Completed lessons 1-3 and the unwritten lesson 4<br>Did random enrichment that Alex found on a desk called 2D quiz | ||

Adults- Mrs. Wolf, Mr. Wolf, Mr. Cav, Mrs. Cav<br><br> | Adults- Mrs. Wolf, Mr. Wolf, Mr. Cav, Mrs. Cav<br><br> | ||

'''12/02/09'''<br> | '''12/02/09'''<br> | ||

<br> | <br> | ||

ROFL Team: Chris H, Sam L, Alex R., MIke M., Kristina K. | ROFL Team: Chris H, Sam L, Alex R., MIke M., Kristina K. | ||

| Line 125: | Line 125: | ||

We gathered around ROFL, brainstormed Ideas to make panels on ROFL. Decided on two options. 1) Wire mesh (as noted below) to cover sides. 2) Interwoven steel wire rope 1/32" Diametor (McMAster Carr Item No. 3498T41). WE researched viable options and found the materials. | We gathered around ROFL, brainstormed Ideas to make panels on ROFL. Decided on two options. 1) Wire mesh (as noted below) to cover sides. 2) Interwoven steel wire rope 1/32" Diametor (McMAster Carr Item No. 3498T41). WE researched viable options and found the materials. | ||

Link to woven wire cloth - can be used for ROFLBot; aluminum preffered - it's the lightest out of all the available materials: http://www.mcmaster.com/#woven-wire-cloth/=4rgxfd<br> | Link to woven wire cloth - can be used for ROFLBot; aluminum preffered - it's the lightest out of all the available materials: http://www.mcmaster.com/#woven-wire-cloth/=4rgxfd<br> | ||

<br> | <br> | ||

Thunderplucker Team: Mike H., Lizzy M., Ben S | Thunderplucker Team: Mike H., Lizzy M., Ben S. | ||

The group of three determined problems with the robot, things that have broken, since it was last overhauled for a competition. It was found that the vertical middle beam on the left side from a rear perspective was bent, the front piece of alluminum to prevent orbit balls from being shot over trailers has broken off, and there is one chicken plucker broken on the top spinner. The team then continued on to possible solutions to the bent bar on next years robot by looking at trade-offs for thicker bars. It was found that doubling the thickness from 1/16" to 1/8" would double the weight and cost, however increase the strength of the robot by slightly more than 65%. | |||

<br> | |||

12/2/09 Attendence: | 12/2/09 Attendence: | ||

| Line 161: | Line 161: | ||

Mike Hartman (Half Meeting) | Mike Hartman (Half Meeting) | ||

Mr. Stoeckl | Mr. Stoeckl | ||

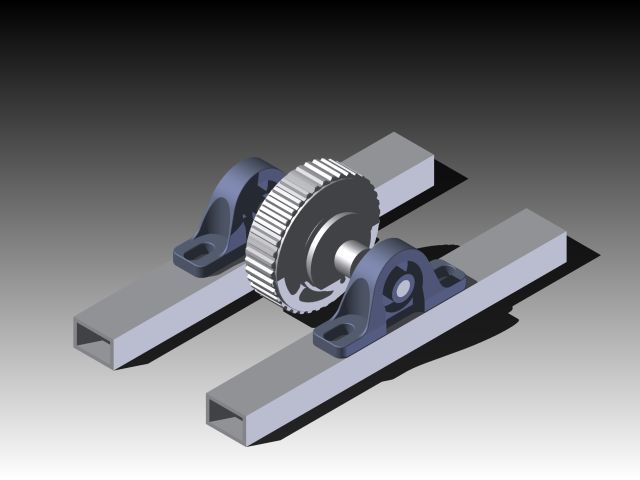

Inventor Team | |||

Made an assembly of a crude drawing just like in build season. | |||

[[Image:Wheel_Image.jpg]] | |||

Revision as of 17:01, 2 December 2009

10/28/09

Form groups for inventor and two repair groups (thunderplucker and mach1511)

Mach. 1511 team: ( Mike M., Kristina Kohl, Jacob Kremer) we marked the holes for the screws to reattach the drive train to the frame. We also brainstormed ideas fo reparing rofflebot. Next week we will drill out the iron bar and will finish up repairs on Mach.

Inventor group:

Sam L, Alex R and Chris H completed lessons 1 and 2 for inventor. We watched Alex W make a chain tensioner on Inventor. Alex explained the benefeits of using Inventor in the process. We then reviewed a prototype of the tensioner for how it would function on Mach 1511. Then we revised the model to reflect our findings.

ThunderPlucker:

Tony, Liz, Tresten, Shauna, Mike Hartman fixed the top spinner on Thunder Plucker and moved the motor. Replaced the missing or broken pluckers on the bottom roller. Moved belts back to where they belong (again...). "i think thats pretty much it..." -Tony

Robot Locations:

Mach. 1511, Trailor

Thunderplucker, Closet

Rofflebot, A-10

Trailer Key is in the closet.

11/4/2009

We went over the eight steps to the engineering process.

Mach. 1511: - (Group 2) Mike M., Becca and Jake Kremer, Shauna ~Mach. was at a demo, we worked on ROFl Bot, came up with a plan to fix the ball pen and to fix the panels. We used the NASAs engineering design sheet to plan out what we needed to do to fix Rofl Bot. We defined a problem: THe Ball pen is broken becauser it has no net and it is floppy and looks like @#$%. We then defined constraints, we want to keep the weight as low as possibvle and keep everything within the robot dimentions. We made several sketches on the SMART board and are saved under a smart doc. I will put them on when I figure out how to. We already started the prototype phase, we used 30lb. test fishing line in place of metal wire. It was ridgid enough to continue on with that design.

Goals:

R ~fix ballpen/net system

R ~reinforce side paneling

R ~reattach drivetrain

R ~make a new net system

R ~contact electrical subteam to see if we have conflicting ideas

thunder plucker:- Tony B, Lizzy M. find probloms that still exists and fix them.

Inventor team

Alex W, Sam L, Alex R, Chris H

Goals:

1. Learn Inventor

2. Finish chain tensioner

Robot Locations:

Mach.~ Trailor

Thunderplucke~ Closet

ROFL Both~ A-10

Leanne Attendence: Alex W., Sam L., Alex R., Chris H., Tony B., Lizzy M,.Mike M., Becca, Jake K., Shaunah, Mr. and Mrs. Wolf

11/18/09

1. On Thunder Plucker, we (Sam L, Alex R, and Chris H) removed broken a ball guide from the top of the shooter.

2. We tightened the bolts on the ball spring guides.

3. We discussed knuts and bolts and weldments and the importance of marking panels so that they would get replaced in the correct location.

4. We discussed measurements (callipers).

ROFLBot : Liz M. , Ben S. Nathan K.

11/18/09

1. We brainstormed ideas to fix the basket following the design process and learned about free body diagrams

2. We looked up cables and ropes on McMaster Carr for material selection considering constraints

Inventor team- Shauna, Alex, Becca, Jake

Completed lessons 1-3 and the unwritten lesson 4

Did random enrichment that Alex found on a desk called 2D quiz

Adults- Mrs. Wolf, Mr. Wolf, Mr. Cav, Mrs. Cav

12/02/09

ROFL Team: Chris H, Sam L, Alex R., MIke M., Kristina K.

We gathered around ROFL, brainstormed Ideas to make panels on ROFL. Decided on two options. 1) Wire mesh (as noted below) to cover sides. 2) Interwoven steel wire rope 1/32" Diametor (McMAster Carr Item No. 3498T41). WE researched viable options and found the materials.

Link to woven wire cloth - can be used for ROFLBot; aluminum preffered - it's the lightest out of all the available materials: http://www.mcmaster.com/#woven-wire-cloth/=4rgxfd

Thunderplucker Team: Mike H., Lizzy M., Ben S.

The group of three determined problems with the robot, things that have broken, since it was last overhauled for a competition. It was found that the vertical middle beam on the left side from a rear perspective was bent, the front piece of alluminum to prevent orbit balls from being shot over trailers has broken off, and there is one chicken plucker broken on the top spinner. The team then continued on to possible solutions to the bent bar on next years robot by looking at trade-offs for thicker bars. It was found that doubling the thickness from 1/16" to 1/8" would double the weight and cost, however increase the strength of the robot by slightly more than 65%.

12/2/09 Attendence:

Alex Wolf

Mr. And Mrs. Wolf

Mike Montemalo

Ben Stoeckl

Chris Hufziger

Elizabeth McChesney

Jacob Kremer

Khristina Kohl

Paul Jennings

Sam Lerman

Shauna Richards

Mike Hartman (Half Meeting)

Mr. Stoeckl

Inventor Team

Made an assembly of a crude drawing just like in build season.