2016:Lifter: Difference between revisions

No edit summary |

No edit summary |

||

| (12 intermediate revisions by 3 users not shown) | |||

| Line 7: | Line 7: | ||

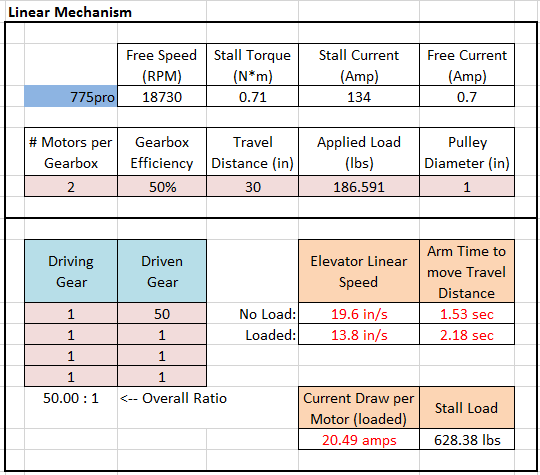

== Motors == | == Motors == | ||

* Two 775pro motors | *Two 775pro motors | ||

* versaplanetary 50:1 with two motor adaptor | *versaplanetary 50:1 with two motor adaptor | ||

* 12 tooth on motor shaft to 12 tooth on mechanism. | *12 tooth on motor shaft to 12 tooth on mechanism. | ||

* | *40A breaker for each motor | ||

* Calculations: | *Calculations: | ||

[[File:Scaler Arm Two VP.PNG]] | |||

[[File:Scaler Arm Two VP.PNG|RTENOTITLE]] | |||

[[File:Scaler linear motor direction.jpg|500x650px]] | |||

== Locking Mechanism == | == Locking Mechanism == | ||

| Line 25: | Line 28: | ||

== Sensors == | == Sensors == | ||

* One Retroreflective sensor (Omron EE-SPY415) to determine when the scaler is at its high end stop. | *One Retroreflective sensor (Omron EE-SPY415) to determine when the scaler is at its high end stop. | ||

* One Optical Flag sensor (OPB815WZ) to determine when the scaler is at its low end stop and home for encoder. | *One Optical Flag sensor (OPB815WZ) to determine when the scaler is at its low end stop and home for encoder. | ||

* One Shaft Encoder (GrayHill 61KS256) for use to measure scaler extension location. | *One Shaft Encoder (GrayHill 61KS256) for use to measure scaler extension location. This is mounted directly on the lift/lower drive shaft | ||

*Limit Switch Sensor interface directly to Talon: [https://docs.google.com/document/d/1D8OIn9jslPQHxiMm34OEeRMzh2Yrja6oCsql93mC-0o/edit https://docs.google.com/document/d/1D8OIn9jslPQHxiMm34OEeRMzh2Yrja6oCsql93mC-0o/edit] | |||

=== Omron EE-SPY415 Detection Distance (+12V Vcc, 10K pullup on Output) (pullup to 12V or 5V gave similar results) === | |||

<ul style="line-height: 20.7999992370605px;"> | |||

<li>Polished shiny metal: trips at 2.0", untrips at 2.75"</li> | |||

<li>Bare brushed aluminum: trips at 1.5", untrips at 2.25"</li> | |||

<li>White paper: trips at 1.5", untrips at 2.25"</li> | |||

<li>Matte black painted metal: trips at 0.75", untrips at 1.0"</li> | |||

</ul> | |||

= Scaler Pivot Arm = | = Scaler Pivot Arm = | ||

| Line 38: | Line 50: | ||

== Sensors == | == Sensors == | ||

= <span style="font-size:x-large;"> | *Optical sensors to determine when the arm is at an end stop -- '''''NOTE: due to switch to potentiometer for absolute positioning, these may be removed!''''' | ||

*One potentiometer to determine where the arm of the scaler is. This is mounted into a gear which mates to another gear on arm pivot. The gearing is NOT 1:1; rather it is geared such that the potentiometer shaft turns 1.4 times for every 1 turn of the arm pivot. This means that if the arm pivot moves 90 degrees, the potentiometer turns 126 degrees. | |||

== <span style="font-size:x-large;">Update 1/26/16</span> == | |||

<span style="font-size:x-large;"><span style="font-size:medium;"><span style="font-size:large;">3.1 What we're working on</span></span></span> | <span style="font-size:x-large;"><span style="font-size:medium;"><span style="font-size:large;">3.1 What we're working on</span></span></span> | ||

| Line 63: | Line 76: | ||

<span style="font-size:medium;">[[File:Scaler assembly 2.PNG|RTENOTITLE]]</span> | <span style="font-size:medium;">[[File:Scaler assembly 2.PNG|RTENOTITLE]]</span> | ||

== <span style="font-size:medium;">Update 2/2/16</span> == | |||

*<span style="line-height: 20.7999992370605px;">Scaler assembly put into shoulder assembly and placed into the final robot assembly</span> | |||

*Still many changes to make, see robot design to-do list -> [https://docs.google.com/spreadsheets/d/1hz4oDlifcAY6ZzfIxCHKYLpOIuN3yy11fZVJu-tDZ0U/edit https://docs.google.com/spreadsheets/d/1hz4oDlifcAY6ZzfIxCHKYLpOIuN3yy11fZVJu-tDZ0U/edit] | |||

*Picture of shoulder assembly in current state v | |||

[[File:Shoulder Assembly 2-2-16.PNG|400px|Shoulder Assembly 2-2-16.PNG]] [[File:Shoulder Assembly Raised 2-2-16.PNG|400px|Shoulder Assembly Raised 2-2-16.PNG]] | |||

== Update 2/3/16 == | |||

Performed stress test in Inventor on the ratchet and pawl for the scaler. | |||

Worked on ratchet and pawl design. | |||

[[File:Ratchet and Pawl 2-3-16.PNG|350px]] | |||

Current design 2-3-16 ^ | |||

Latest revision as of 10:19, 7 February 2016

The Plan

We have come to the conclusion that the best method of scaling the castle near the end of the match is using a telescoping arm to latch onto the bar and then lift with the arm.

Arm Extension and Lift

Motors

- Two 775pro motors

- versaplanetary 50:1 with two motor adaptor

- 12 tooth on motor shaft to 12 tooth on mechanism.

- 40A breaker for each motor

- Calculations:

Locking Mechanism

This is used to keep the arm locked in the retracted position (for when the robot is lifted in the air). The current plan is to use a ratcheting mechanism on the extension/lifter drive shaft:

- Ratchet gear - has teeth inclined slightly tangental in a uniform direction around the gear

- Pawl - a solid block which engages the teeth in the above gear, preventing the gear from spinning in one direction (in our case, the direction that would allow the scaler arm to extend/the robot to fall!)

- Hightec HS322-HD Servo - used to lift and lower the Pawl. This should be lifting the pawl during arm extension and lowering it during retraction when lifting.

The pawl engagement is such that the servo CANNOT lift it back up again once the ratchet has back-pressure on it (from the robot being in the air, or whatever). However, if necessary, the pawl can be disengaged by having the servo trying to lift it and then turning the ratchet gear slightly in the arm retract/robot lift direction.

Sensors

- One Retroreflective sensor (Omron EE-SPY415) to determine when the scaler is at its high end stop.

- One Optical Flag sensor (OPB815WZ) to determine when the scaler is at its low end stop and home for encoder.

- One Shaft Encoder (GrayHill 61KS256) for use to measure scaler extension location. This is mounted directly on the lift/lower drive shaft

- Limit Switch Sensor interface directly to Talon: https://docs.google.com/document/d/1D8OIn9jslPQHxiMm34OEeRMzh2Yrja6oCsql93mC-0o/edit

Omron EE-SPY415 Detection Distance (+12V Vcc, 10K pullup on Output) (pullup to 12V or 5V gave similar results)

- Polished shiny metal: trips at 2.0", untrips at 2.75"

- Bare brushed aluminum: trips at 1.5", untrips at 2.25"

- White paper: trips at 1.5", untrips at 2.25"

- Matte black painted metal: trips at 0.75", untrips at 1.0"

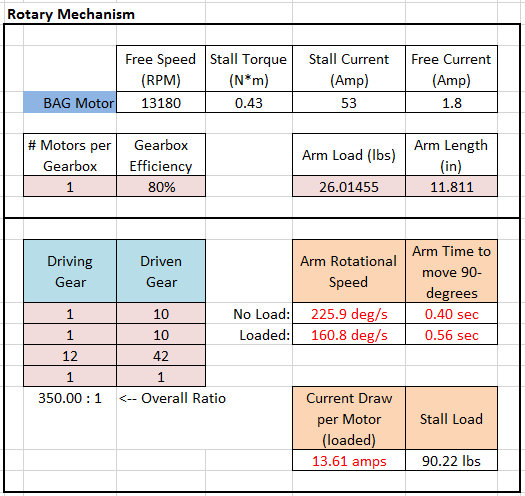

Scaler Pivot Arm

Motors

Sensors

- Optical sensors to determine when the arm is at an end stop -- NOTE: due to switch to potentiometer for absolute positioning, these may be removed!

- One potentiometer to determine where the arm of the scaler is. This is mounted into a gear which mates to another gear on arm pivot. The gearing is NOT 1:1; rather it is geared such that the potentiometer shaft turns 1.4 times for every 1 turn of the arm pivot. This means that if the arm pivot moves 90 degrees, the potentiometer turns 126 degrees.

Update 1/26/16

3.1 What we're working on

- Design rollers/stops for the arm stages

- Design lightning holes

- Design motor mountings and figure out how to attach to the drivebase

- Send parts to chamtek

- Finish CAD work

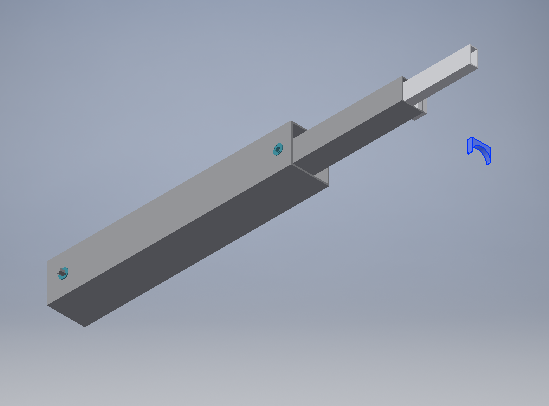

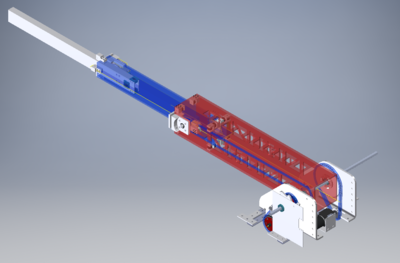

3.2 Photos

This is the hook we will be using.

This is the actual arm we designed.

Update 2/2/16

- Scaler assembly put into shoulder assembly and placed into the final robot assembly

- Still many changes to make, see robot design to-do list -> https://docs.google.com/spreadsheets/d/1hz4oDlifcAY6ZzfIxCHKYLpOIuN3yy11fZVJu-tDZ0U/edit

- Picture of shoulder assembly in current state v

Update 2/3/16

Performed stress test in Inventor on the ratchet and pawl for the scaler.

Worked on ratchet and pawl design.

Current design 2-3-16 ^