2024:Hang: Difference between revisions

No edit summary |

No edit summary |

||

| (18 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

= <span style="font-size: 14pt;">'''1/6/2024'''</span> = | |||

*<span style="font-size: 12pt;">Discussed and prototyped on CAD a spring gate hook</span> | |||

<span style="font-size: 12pt;"></span> | |||

<span style="font-size: 12pt;"> | |||

= <span style="font-size: 12pt;"></span><span style="font-size: 14pt;">'''1/7/2024'''</span> = | |||

*<span style="font-size: 12pt;">Prototyped two different types of hooks</span> | *<span style="font-size: 12pt;">Prototyped two different types of hooks</span> | ||

*<span style="font-size: 12pt;">Tested both, worked well in holding on the chain and preventing slipping</span> | *<span style="font-size: 12pt;">Tested both, worked well in holding on the chain and preventing slipping</span> | ||

= <span style="font-size: 14pt;">'''1/13/2024'''</span> = | |||

<span style="font-size: 14pt;">'''1/13/2024'''</span><p><span style="font-size: 12pt;">We started the meeting today by taking inspiration from our 2022 design for the hang mechanism. Upon further research, we decided to modify the original design to better suit our needs for this years game. We started by deciding to try a different way to prevent the arm from moving. We used a Ratchet and Pawl mechanism in 2022 and ended up having lots of problems with it, so we are going to try a worm gear this year (we will start a prototype for this once the one we ordered comes in). We also took inspiration from PRi3D of the North's 2024 robot reveal video. The hang mechanism that they used had the hook inside of the arm instead of placed on top, which would help reduce weight and will (hopefully) have less problems. We decided to stick with the hook that we tested during prototyping. </span></p><p><span style="font-size: 12pt;">We then worked on calculations of the hang mechanism. Based on the height of the drive base and the range that we wanted to be able to hang on the chain from (when the chain is 36" from the ground or lower), we decided that the arms should be 36.5" tall, the side that our hook will stick out on will be 2" long, and side perpendicular to that will be 1.5" long. We also spent some time discussing with the game piece group to see if the hang mechanism would get in the way of the intake/shooter. Both hooks will be completely independent from each other. In 2022 we had them connected and it was extremely hard to access anything if it broke, so we decided against connecting them. We then began working on the CAD for the arms. </span></p> | <p><span style="font-size: 12pt;">We started the meeting today by taking inspiration from our 2022 design for the hang mechanism. Upon further research, we decided to modify the original design to better suit our needs for this years game. We started by deciding to try a different way to prevent the arm from moving. We used a Ratchet and Pawl mechanism in 2022 and ended up having lots of problems with it, so we are going to try a worm gear this year (we will start a prototype for this once the one we ordered comes in). We also took inspiration from PRi3D of the North's 2024 robot reveal video. The hang mechanism that they used had the hook inside of the arm instead of placed on top, which would help reduce weight and will (hopefully) have less problems. We decided to stick with the hook that we tested during prototyping. </span></p> | ||

<p><span style="font-size: 12pt;">We then worked on calculations of the hang mechanism. Based on the height of the drive base and the range that we wanted to be able to hang on the chain from (when the chain is 36" from the ground or lower), we decided that the arms should be 36.5" tall, the side that our hook will stick out on will be 2" long, and side perpendicular to that will be 1.5" long. We also spent some time discussing with the game piece group to see if the hang mechanism would get in the way of the intake/shooter. Both hooks will be completely independent from each other. In 2022 we had them connected and it was extremely hard to access anything if it broke, so we decided against connecting them. We then began working on the CAD for the arms. </span><span style="font-size: 12pt;"></span></p> | |||

<span style="font-size: 14pt;">'''1/14/2024'''</span><p><span style="font-size: 12pt;">We ultimately decided to go with a Ratchet and Pawl design for the hang mechanism. Because we have more experience with it, we can improve the design and try to fix problems that we ran into before instead of trying to design something completely new. One group took the Ratchet and Pawl design from 2022 and shortened the axel length for it. Additionally, we decided that having smaller teeth on the ratchet would allow for us to be more precise and have less distance to pull the pawl. We will continue modifying the design as we see fit. </span></p><p><span style="font-size: 12pt;">The second group for hang worked on more calculations and working on the arm design with the constant force spring. We started by calculating the force that would be on the rollers on each side of the interior arm. Each roller needs to be able to hold 18.75 lbf. Additionally, we came to the conclusion that having a 1/8" thick arm would be much stronger than a 1/16" thick arm. The dimensions of the external arm are 2" x 2" and the internal arm is 1" x 1". Since we will be using the robot frequently and pushing it as much as possible, we wanted to make the arm design extremely robust so it doesn't bend or break. We designed the spring bracket for the constant force spring and designed the bearing blocks for the 1" tube and decided to use a 1/4" bearing. </span></p><p><span style="font-size: 12pt;">The hang sub team decided to put the hang mechanism on plates on top of the drive base. This will allow electrical space underneath our design and will also allow us to adjust the design depending on where the center of gravity in our robot is. We want to make sure our robot does not tip when we pull up onto the chain, and we don't want to tip when scoring in the Trap, so having a bit of wiggle room with the location of the hang mechanism was important for us. </span></p> | = <span style="font-size: 14pt;">'''1/14/2024'''</span> = | ||

<p><span style="font-size: 12pt;">We ultimately decided to go with a Ratchet and Pawl design for the hang mechanism. Because we have more experience with it, we can improve the design and try to fix problems that we ran into before instead of trying to design something completely new. One group took the Ratchet and Pawl design from 2022 and shortened the axel length for it. Additionally, we decided that having smaller teeth on the ratchet would allow for us to be more precise and have less distance to pull the pawl. We will continue modifying the design as we see fit. </span></p> | |||

<p><span style="font-size: 12pt;">The second group for hang worked on more calculations and working on the arm design with the constant force spring. We started by calculating the force that would be on the rollers on each side of the interior arm. Each roller needs to be able to hold 18.75 lbf. Additionally, we came to the conclusion that having a 1/8" thick arm would be much stronger than a 1/16" thick arm. The dimensions of the external arm are 2" x 2" and the internal arm is 1" x 1". Since we will be using the robot frequently and pushing it as much as possible, we wanted to make the arm design extremely robust so it doesn't bend or break. We designed the spring bracket for the constant force spring and designed the bearing blocks for the 1" tube and decided to use a 1/4" bearing. </span></p> | |||

<p><span style="font-size: 12pt;">The hang sub team decided to put the hang mechanism on plates on top of the drive base. This will allow electrical space underneath our design and will also allow us to adjust the design depending on where the center of gravity in our robot is. We want to make sure our robot does not tip when we pull up onto the chain, and we don't want to tip when scoring in the Trap, so having a bit of wiggle room with the location of the hang mechanism was important for us. </span></p> | |||

= <span style="font-size: 14pt;">'''1/18/2024'''</span>= | |||

*<span style="font-size: 12pt;">Added bearing block holes to hook</span> | *<span style="font-size: 12pt;">Added bearing block holes to hook</span> | ||

*<span style="font-size: 12pt;">Discussed and created CAD design for ratchet strap attachment to hook</span> | *<span style="font-size: 12pt;">Discussed and created CAD design for ratchet strap attachment to hook</span> | ||

| Line 60: | Line 58: | ||

= '''<span style="font-size: 14pt;">1/20/2024</span>''' = | |||

*<span style="font-size: 12pt;">Attached new ratchet strap clamp to the hook assembly</span> | *<span style="font-size: 12pt;">Attached new ratchet strap clamp to the hook assembly</span> | ||

| Line 74: | Line 71: | ||

*<span style="font-size: 12pt;">Decided to use the same ratchet strap on this robot as 2022 </span> | *<span style="font-size: 12pt;">Decided to use the same ratchet strap on this robot as 2022 </span> | ||

*<span style="font-size: 12pt;">Started designing the spool that the ratchet goes around</span> | *<span style="font-size: 12pt;">Started designing the spool that the ratchet goes around</span> | ||

= <span style="font-size: 14pt;">'''1/23/2024'''</span> = | |||

*<span style="font-size: 12pt;">Worked on determining placement and geometry of electric Solenoid</span> | |||

*<span style="font-size: 12pt;">Worked on determining placement and geometry of electric Solenoid | |||

</span> | |||

*<span style="font-size: 12pt;">Began CADing pivoting bracket for electric Solenoid attachment </span> | *<span style="font-size: 12pt;">Began CADing pivoting bracket for electric Solenoid attachment </span> | ||

*<span style="font-size: 12pt;">Created shop drawings for hook | *<span style="font-size: 12pt;">Created shop drawings for hook</span> | ||

</span> | |||

*<span style="font-size: 12pt;">Discussed placement of arm and orientation of winch assembly</span> | *<span style="font-size: 12pt;">Discussed placement of arm and orientation of winch assembly</span> | ||

= '''<span style="font-size: 14pt;">1/24/2024</span>''' = | |||

*<span style="font-size: 12pt;">Continued working on fixing winch geometry</span> | *<span style="font-size: 12pt;">Continued working on fixing winch geometry</span> | ||

='''<span style="font-size: 14pt;">1/25/2024</span>''' = | |||

*<span style="font-size: 12pt;">Worked on rearranging our initial design for the winch</span> | |||

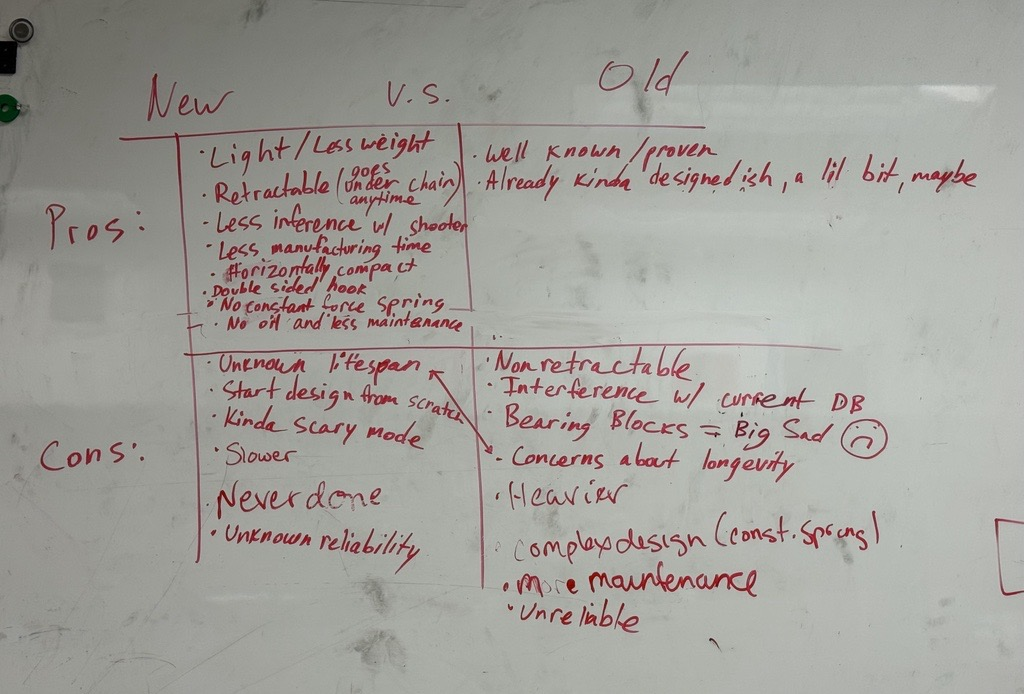

*<span style="font-size: 12pt;">Discovered the potential possibility of designing an entirely new hang design based on the [https://www.chiefdelphi.com/t/chameleon-climber-bistable-rollable-composite-climber/450394 Chameleon Climber]</span> | |||

*<span style="font-size: 12pt;">Made a pros/cons list, discovered that the Chameleon design is our best option</span> | |||

*<span style="font-size: 12pt;">Started adapting the new design to suit our needs</span> | |||

*<span style="font-size: 12pt;">Began placement of Chameleon in our current hang assembly</span> | |||

<span style="font-size: 12pt;"></span> | <span style="font-size: 12pt;"></span> | ||

<span style="font-size: 12pt;"></span>[[File:Pros-Cons.png|300px|left|frame]] | |||

</span> | |||

<span style="font-size: 14pt;">'''1/28/2024'''</span> | = '''<span style="font-size: 14pt;">1/27/2024</span>''' = | ||

*<span style="font-size: 12pt;">Finished Hook</span> | |||

*<span style="font-size: 12pt;">Started final hang assembly</span> | |||

*<span style="font-size: 12pt;">Figured out geometries and placements of many items</span> | |||

*<span style="font-size: 12pt;">Started shop drawing</span> | |||

= <span style="font-size: 14pt;">'''1/28/2024'''</span> = | |||

*<span style="font-size: 12pt;">Finalized placement of hang on robot</span> | *<span style="font-size: 12pt;">Finalized placement of hang on robot</span> | ||

*<span style="font-size: 12pt;">Almost finished final hang assemblies (left and right)</span> | *<span style="font-size: 12pt;">Almost finished final hang assemblies (left and right)</span> | ||

*<span style="font-size: 12pt;">Started CAD for the hang tube funnel</span> | *<span style="font-size: 12pt;">Started CAD for the hang tube funnel</span> | ||

*<span style="font-size: 12pt;">Tentatively decided on using an Omron retroreflective sensor to detect reflective tape wrapped around the boat hook (carbon fiber tube)</span> | *<span style="font-size: 12pt;">Tentatively decided on using an Omron retroreflective sensor to detect reflective tape wrapped around the boat hook (carbon fiber tube)</span> | ||

'''<span style="font-size: 14pt;">1/30/2024</span>''' | <span style="font-size: 12pt;"></span> | ||

<span style="font-size: 12pt;"></span> | |||

='''<span style="font-size: 14pt;">1/30/2024</span>''' = | |||

*<span style="font-size: 12pt;">Finished all Harris Drawings</span> | *<span style="font-size: 12pt;">Finished all Harris Drawings</span> | ||

*<span style="font-size: 12pt;">Added more light(e)ning holes to the hang assembly</span> | *<span style="font-size: 12pt;">Added more light(e)ning holes to the hang assembly</span> | ||

| Line 156: | Line 181: | ||

*<span style="font-size: 12pt;">Reevaluated sensors for hang, need to decide between Allen-Bradley retroreflective sensor and limit switch</span> | *<span style="font-size: 12pt;">Reevaluated sensors for hang, need to decide between Allen-Bradley retroreflective sensor and limit switch</span> | ||

*<span style="font-size: 12pt;">Got final hang assemblies finished and placed in the Final Robot Assembly!!! Yay!</span> | *<span style="font-size: 12pt;">Got final hang assemblies finished and placed in the Final Robot Assembly!!! Yay!</span> | ||

='''<span style="font-size: 14pt;">2/10/2024</span>''' = | |||

*<span style="font-size: 12pt;">Gathered components for assembly and hook inventory of Harris parts</span> | *<span style="font-size: 12pt;">Gathered components for assembly and hook inventory of Harris parts</span> | ||

*<span style="font-size: 12pt;">Painted parts</span> | *<span style="font-size: 12pt;">Painted parts</span> | ||

*<span style="font-size: 12pt;">Started assembly of both left and right lift</span> | *<span style="font-size: 12pt;">Started assembly of both left and right lift</span> | ||

<span style="font-size: 12pt;"></span>= '''<span style="font-size: 14pt;">2/11/2024</span>''' ='''<span style="font-size: 14pt;"></span>''' | |||

<span style="font-size: 12pt;"></span> | |||

<span style="font-size: 14pt;"> | |||

*<span style="font-size: 12pt;">Broached and sanded ABS drum inserts</span> | *<span style="font-size: 12pt;">Broached and sanded ABS drum inserts</span> | ||

*<span style="font-size: 12pt;">Removed foam handle from carbon fiber tubes</span> | *<span style="font-size: 12pt;">Removed foam handle from carbon fiber tubes</span> | ||

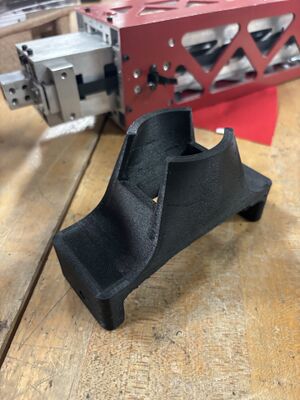

*<span style="font-size: 12pt;">Redesigned hooks (V3, V4, V5) for aesthetic/weight reduction purposes</span> | *<span style="font-size: 12pt;">Redesigned hooks (V3, V4, V5) for aesthetic/weight reduction purposes</span> | ||

'''<span style="font-size: 14pt;"></span>''' | |||

= '''<span style="font-size: 14pt;">2/15/2024</span>''' = | |||

<span style="font-size: 12pt;">Since the last update, we have been working on assembly of one hang module. Both motor mount plates are on the robot, and we're waiting on our Winch Drum Inserts to be completed.</span> | <span style="font-size: 12pt;">Since the last update, we have been working on assembly of one hang module. Both motor mount plates are on the robot, and we're waiting on our Winch Drum Inserts to be completed.</span> | ||

| Line 191: | Line 212: | ||

*<span style="font-size: 12pt;">Pull the CF Tube up so that it's rolled, '''then''' mount the Hang Tube Funnel</span> | *<span style="font-size: 12pt;">Pull the CF Tube up so that it's rolled, '''then''' mount the Hang Tube Funnel</span> | ||

*<span style="font-size: 12pt;">Attach the hook to the CF Tube</span> | *<span style="font-size: 12pt;">Attach the hook to the CF Tube</span> | ||

<span style="font-size: 12pt;">And you're done! :)</span> | <span style="font-size: 12pt;">And you're done! :)</span> | ||

<span style="font-size: 12pt;"></span>[[File:HangModule.jpeg|300px|left|thumb]] | |||

= '''<span style="font-size: 14pt;">2/17/2024</span>''' = | |||

<span style="font-size: 12pt;">We've finished assembling the two hang modules we have available to us! We're now waiting on our new pair of hang inserts, and once we have those ready, we can replace our right side drum assembly. We're also waiting on our CF hooks and our Hang Tube Funnel to print for us to test. We discovered that our Retroreflective Sensor brackets were too short, so we remade them to be slightly longer via a new metal plate. An issue we've encountered with our CF hooks is that the spool doesn't immediately push the hook up when spun, instead bunching up/stalling. We hope to fix this issue by installing a bar that forces the tube to go up instead of spinning idly. RCS has successfully wired the majority of our sensors, so hopefully we can get the assembly programmed and tested soon!</span> | |||

<span style="font-size: 12pt;"></span> | <span style="font-size: 12pt;"></span> | ||

<span style="font-size: 12pt;"></span> | = '''<span style="font-size: 14pt;">2/21/2024</span>''' = | ||

<br> | |||

*<span style="font-size: 12pt;">Printed new CF Hooks</span> | |||

*<span style="font-size: 12pt;">Made Hang Tube Funnel V3 out of CF so it doesn't snap again while hanging</span> | |||

*<span style="font-size: 12pt;">Drilled holes into the ratchet to be bolted to the Winch Drum Insert</span> | |||

<span style="font-size: 12pt;"></span>[[File:Thumbnail IMG 0823.jpg|300px|left|thumb]] | |||

[[File:Thumbnail IMG 0822.jpg|300px|left|thumb]] | |||

| Line 211: | Line 349: | ||

<span style="font-size: | = '''<span style="font-size: 14pt;">2/23/2024</span>''' = | ||

*<span style="font-size: 12pt;">Cleaned up and modified Hang Tube Funnel(s) V2</span><br> | |||

*<span style="font-size: 12pt;">Cleaned up new Tube Guides</span> | |||

Latest revision as of 15:34, 23 February 2024

1/6/2024

- Discussed and prototyped on CAD a spring gate hook

1/7/2024

- Prototyped two different types of hooks

- Tested both, worked well in holding on the chain and preventing slipping

1/13/2024

We started the meeting today by taking inspiration from our 2022 design for the hang mechanism. Upon further research, we decided to modify the original design to better suit our needs for this years game. We started by deciding to try a different way to prevent the arm from moving. We used a Ratchet and Pawl mechanism in 2022 and ended up having lots of problems with it, so we are going to try a worm gear this year (we will start a prototype for this once the one we ordered comes in). We also took inspiration from PRi3D of the North's 2024 robot reveal video. The hang mechanism that they used had the hook inside of the arm instead of placed on top, which would help reduce weight and will (hopefully) have less problems. We decided to stick with the hook that we tested during prototyping.

We then worked on calculations of the hang mechanism. Based on the height of the drive base and the range that we wanted to be able to hang on the chain from (when the chain is 36" from the ground or lower), we decided that the arms should be 36.5" tall, the side that our hook will stick out on will be 2" long, and side perpendicular to that will be 1.5" long. We also spent some time discussing with the game piece group to see if the hang mechanism would get in the way of the intake/shooter. Both hooks will be completely independent from each other. In 2022 we had them connected and it was extremely hard to access anything if it broke, so we decided against connecting them. We then began working on the CAD for the arms.

1/14/2024

We ultimately decided to go with a Ratchet and Pawl design for the hang mechanism. Because we have more experience with it, we can improve the design and try to fix problems that we ran into before instead of trying to design something completely new. One group took the Ratchet and Pawl design from 2022 and shortened the axel length for it. Additionally, we decided that having smaller teeth on the ratchet would allow for us to be more precise and have less distance to pull the pawl. We will continue modifying the design as we see fit.

The second group for hang worked on more calculations and working on the arm design with the constant force spring. We started by calculating the force that would be on the rollers on each side of the interior arm. Each roller needs to be able to hold 18.75 lbf. Additionally, we came to the conclusion that having a 1/8" thick arm would be much stronger than a 1/16" thick arm. The dimensions of the external arm are 2" x 2" and the internal arm is 1" x 1". Since we will be using the robot frequently and pushing it as much as possible, we wanted to make the arm design extremely robust so it doesn't bend or break. We designed the spring bracket for the constant force spring and designed the bearing blocks for the 1" tube and decided to use a 1/4" bearing.

The hang sub team decided to put the hang mechanism on plates on top of the drive base. This will allow electrical space underneath our design and will also allow us to adjust the design depending on where the center of gravity in our robot is. We want to make sure our robot does not tip when we pull up onto the chain, and we don't want to tip when scoring in the Trap, so having a bit of wiggle room with the location of the hang mechanism was important for us.

1/18/2024

- Added bearing block holes to hook

- Discussed and created CAD design for ratchet strap attachment to hook

1/20/2024

- Attached new ratchet strap clamp to the hook assembly

- Decided we're driving each arm with 1 NEO, for 2 NEOs total

- Using 1 electric solenoid per each arm (to control the pawl), 2 electric solenoids total

- Changed one of our bearing block designs to minimize the number of smaller bearing blocks we have to make

- We decided to make one big bearing block instead of cutting two smaller ones

- Started analyzing gear ratios

- Decided to use the same ratchet strap on this robot as 2022

- Started designing the spool that the ratchet goes around

1/23/2024

- Worked on determining placement and geometry of electric Solenoid

- Began CADing pivoting bracket for electric Solenoid attachment

- Created shop drawings for hook

- Discussed placement of arm and orientation of winch assembly

1/24/2024

- Continued working on fixing winch geometry

1/25/2024

- Worked on rearranging our initial design for the winch

- Discovered the potential possibility of designing an entirely new hang design based on the Chameleon Climber

- Made a pros/cons list, discovered that the Chameleon design is our best option

- Started adapting the new design to suit our needs

- Began placement of Chameleon in our current hang assembly

1/27/2024

- Finished Hook

- Started final hang assembly

- Figured out geometries and placements of many items

- Started shop drawing

1/28/2024

- Finalized placement of hang on robot

- Almost finished final hang assemblies (left and right)

- Started CAD for the hang tube funnel

- Tentatively decided on using an Omron retroreflective sensor to detect reflective tape wrapped around the boat hook (carbon fiber tube)

1/30/2024

- Finished all Harris Drawings

- Added more light(e)ning holes to the hang assembly

- Worked more on hang tube funnel

- Reevaluated sensors for hang, need to decide between Allen-Bradley retroreflective sensor and limit switch

- Got final hang assemblies finished and placed in the Final Robot Assembly!!! Yay!

2/10/2024

- Gathered components for assembly and hook inventory of Harris parts

- Painted parts

- Started assembly of both left and right lift

= 2/11/2024 =

- Broached and sanded ABS drum inserts

- Removed foam handle from carbon fiber tubes

- Redesigned hooks (V3, V4, V5) for aesthetic/weight reduction purposes

2/15/2024

Since the last update, we have been working on assembly of one hang module. Both motor mount plates are on the robot, and we're waiting on our Winch Drum Inserts to be completed.

Assembly Order

- Assemble Mid Axle and Motor Axle on plate

- Attach the plate (with the motor on it) to the robot, referencing the CAD for where to place the plate

- 2 Bolts on both ends of the Motor Mounting Plate, 2 bolts for the bracket that folds under the C-Channel

- Assemble the Drum Axle on-robot, it won't fit otherwise

- Make sure the CF Tube is facing the right way (check the CAD)

- Reference the Assembly Drawings on the Hang shelf/in the Shop Binder

- Attach the Drum Axle Bracket to the C-Channel

- Mount the Pawl and Leaf Switch

- Mount the Electric Solenoid (make sure none of the bolts are too tight, otherwise the spring won't spring correctly)

- Mount the Retroreflective Sensor Bracket, then the Retro Sensor

- Pull the CF Tube up so that it's rolled, then mount the Hang Tube Funnel

- Attach the hook to the CF Tube

And you're done! :)

2/17/2024

We've finished assembling the two hang modules we have available to us! We're now waiting on our new pair of hang inserts, and once we have those ready, we can replace our right side drum assembly. We're also waiting on our CF hooks and our Hang Tube Funnel to print for us to test. We discovered that our Retroreflective Sensor brackets were too short, so we remade them to be slightly longer via a new metal plate. An issue we've encountered with our CF hooks is that the spool doesn't immediately push the hook up when spun, instead bunching up/stalling. We hope to fix this issue by installing a bar that forces the tube to go up instead of spinning idly. RCS has successfully wired the majority of our sensors, so hopefully we can get the assembly programmed and tested soon!

2/21/2024

- Printed new CF Hooks

- Made Hang Tube Funnel V3 out of CF so it doesn't snap again while hanging

- Drilled holes into the ratchet to be bolted to the Winch Drum Insert

2/23/2024

- Cleaned up and modified Hang Tube Funnel(s) V2

- Cleaned up new Tube Guides