2011:Mechanical 2 2.22: Difference between revisions

Mechanical2 (talk | contribs) No edit summary |

Mechanical2 (talk | contribs) No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 11: | Line 11: | ||

= Tasks to Complete = | = Tasks to Complete = | ||

1. Full system check. | |||

2. Manipulator exchange. <br>A- Remove Wire Guard from Manipulator #1.<br>B- Select a clearance drill for the bolts and chuck into a drill.<br>C- Remove Banner Sensors from Manipulator #1 and attach to Manipulator #2<br>D- Remove Wire Guard, motor, transmission and bracket from Manipulator #1.<br>E- Remove pulley from motor shaft.<br>F- Place new chain sprocket and chain onto shaft together. (Sprocket and chain are in the Red Soft Side tool bag)<br>G- Mount motor/ transmission/ sprocket/ chain onto Manipulator #2.<br>H- Put master link into new chain.<br>I- Mark the shims that are between the Wrist Arm Side and the Arm so that you can tell Robot Right from Robot Left and Front from Back.<br>J- Disconnect all wires and carefully pull them away from wrist area.<br>K- Remove eight nuts and bolts from Wrist Arm Side and save.<br>L- Careful remove Manipulator #1 from arm and keep track of shims (Place them in a preplanned position).<br>M- Use the shims to draw the hole pattern on Manipulator #2, be extremely careful to keep the orientation correct.<br>N- Use the marked holes to drill holes in the new manipulator.<br>O- Deburr Manipulator #2 and attach to arm.<br>P- Retention chains.<br>Q- Reconnect wires with electrical team help and guidance. <br>R- Screw Wire Guard on to Manipulator #2. (there are specific screws in a box in the Red Soft Side tool bag that fit into the transmissions)<br>S- Measure the manipulator position relative to the Frame Perimeter. <br>Remember the frame perimeter is;<br><br> | |||

[[Image:2011-03-21.jpg]]<br>So where our frame "sunk in" during welding does not count.<br>It's a straight line from corner to corner projected vertically that determines the frame perimeter.<br>T- If the Manipulator will not stay in the Frame Perimeter with an uber-tube add 4 more 1/4-20 bolts to lock it's position. | |||

3. Driver practice and matches. | 3. Driver practice and matches. | ||

<br> | 4. Minibot nest exchange evaluation and prep work. <br><br> | ||

<br> | <br> | ||

<br> | <br> | ||

<br> | <br> | ||

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX | XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX | ||

| Line 69: | Line 55: | ||

5 Design minibot roof and backstop | 5 Design minibot roof and backstop | ||

<br> | <br> | ||

Complete; | Complete; | ||

1 Order McmasterCarr parts <br> | 1 Order McmasterCarr parts <br> | ||

= Materials Needed = | = Materials Needed = | ||

| Line 79: | Line 65: | ||

*task | *task | ||

**sub-task | **sub-task | ||

**sub-task | **sub-task | ||

*task | *task | ||

*1- Spring load top and bottom<br>2- Remove corner from top for park position<br>3- Chain<br>4- 2 half per side<br>5- 1 ¾ wrist <br>6- Skid plate<br>7- Sensor field of view<br>8- hard stops open and closed<br>9- Add bumper to keep tube out of corners<br>10- stronger wrist | *1- Spring load top and bottom<br>2- Remove corner from top for park position<br>3- Chain<br>4- 2 half per side<br>5- 1 ¾ wrist <br>6- Skid plate<br>7- Sensor field of view<br>8- hard stops open and closed<br>9- Add bumper to keep tube out of corners<br>10- stronger wrist | ||

2737T102 12 teeth 3/8 id<br> | 2737T102 12 teeth 3/8 id<br> | ||

*<br> | *<br> | ||

Latest revision as of 08:36, 22 March 2011

Attendance

Start time:

End time:

Members present:

Members Attending Next Meeting:

Tasks to Complete

1. Full system check.

2. Manipulator exchange.

A- Remove Wire Guard from Manipulator #1.

B- Select a clearance drill for the bolts and chuck into a drill.

C- Remove Banner Sensors from Manipulator #1 and attach to Manipulator #2

D- Remove Wire Guard, motor, transmission and bracket from Manipulator #1.

E- Remove pulley from motor shaft.

F- Place new chain sprocket and chain onto shaft together. (Sprocket and chain are in the Red Soft Side tool bag)

G- Mount motor/ transmission/ sprocket/ chain onto Manipulator #2.

H- Put master link into new chain.

I- Mark the shims that are between the Wrist Arm Side and the Arm so that you can tell Robot Right from Robot Left and Front from Back.

J- Disconnect all wires and carefully pull them away from wrist area.

K- Remove eight nuts and bolts from Wrist Arm Side and save.

L- Careful remove Manipulator #1 from arm and keep track of shims (Place them in a preplanned position).

M- Use the shims to draw the hole pattern on Manipulator #2, be extremely careful to keep the orientation correct.

N- Use the marked holes to drill holes in the new manipulator.

O- Deburr Manipulator #2 and attach to arm.

P- Retention chains.

Q- Reconnect wires with electrical team help and guidance.

R- Screw Wire Guard on to Manipulator #2. (there are specific screws in a box in the Red Soft Side tool bag that fit into the transmissions)

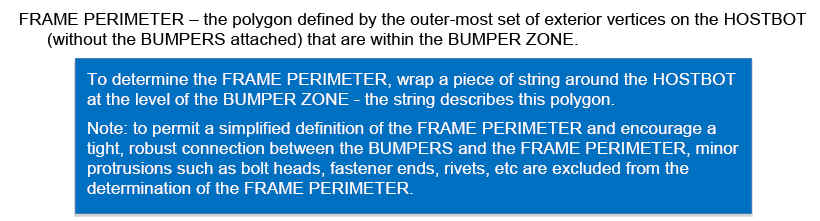

S- Measure the manipulator position relative to the Frame Perimeter.

Remember the frame perimeter is;

So where our frame "sunk in" during welding does not count.

It's a straight line from corner to corner projected vertically that determines the frame perimeter.

T- If the Manipulator will not stay in the Frame Perimeter with an uber-tube add 4 more 1/4-20 bolts to lock it's position.

3. Driver practice and matches.

4. Minibot nest exchange evaluation and prep work.

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

At FLR

1 Put bolts in the corners of the upper structure

2 Put on chain guard

3 Put on minibot roof

Before FLR

1 Order spare parts from Harris

2 Redesign manipulator wheel shafts for maintainability

3 Design chain guard

4 Design manipulator wheel guard

5 Design minibot roof and backstop

Complete;

1 Order McmasterCarr parts

Materials Needed

- task

- sub-task

- sub-task

- task

- 1- Spring load top and bottom

2- Remove corner from top for park position

3- Chain

4- 2 half per side

5- 1 ¾ wrist

6- Skid plate

7- Sensor field of view

8- hard stops open and closed

9- Add bumper to keep tube out of corners

10- stronger wrist

2737T102 12 teeth 3/8 id