2012:Shooter and Collector 01.17: Difference between revisions

No edit summary |

Mechanical1 (talk | contribs) No edit summary |

||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

'''Start time: '''5:00 PM | |||

'''End time: '''10:00 PM | |||

''' | '''Members present: '''Alex W, Mike M, Matthieu D, Ciana R, Alex R, Danny S, Molly C, Brianna M, Nick, and others | ||

''' | '''Members Attending Next Meeting: '''Lots and lots of people | ||

= Tasks Completed = | |||

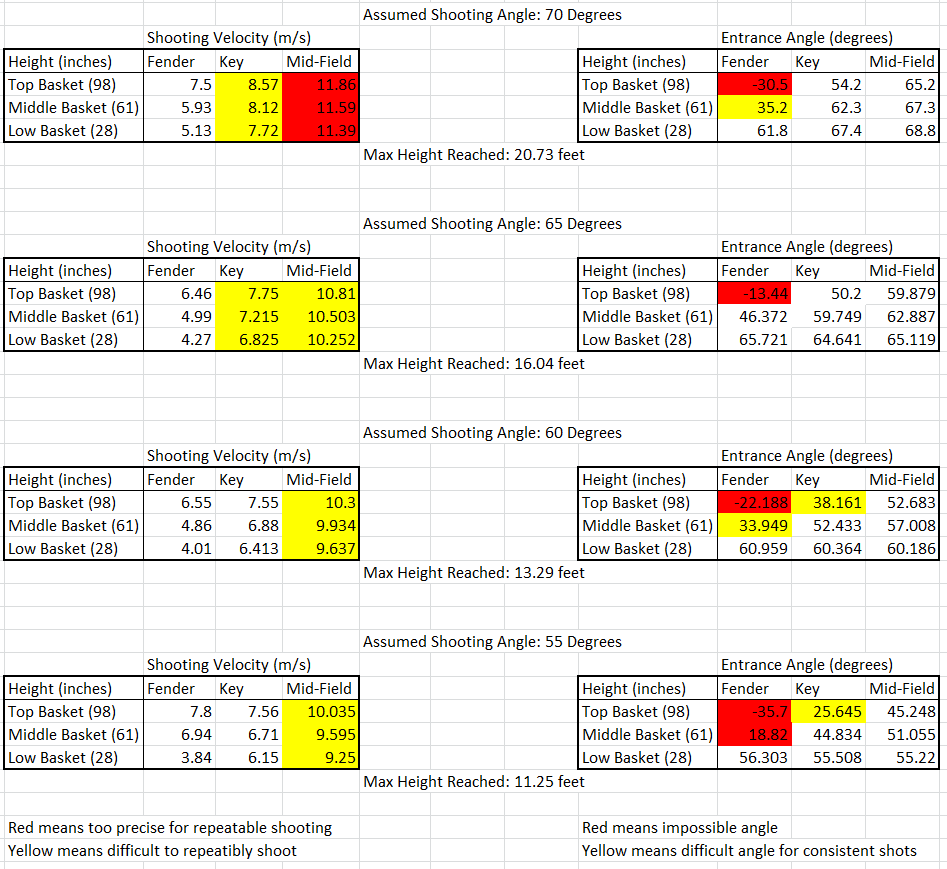

*Shooter Math Model | |||

[[File:Shooter Math Model.png]] | |||

Conclusions | |||

70 degree is the baseline angle.<br/>Shoots a little high<br/>Cannot accurately shoot from the mid field<br/>It will work in many situations | |||

<span style="background-color: rgb(153,204,0)">65 degree angle</span><br/>Requires moderate precision to shoot in each hoop from midfield and the key<br/>All angle except the top fender will work<br/>A great general use angle | |||

60 degree angle<br/>Does not require much precision to shoot in hoops from any distance<br/>The top key and middle fender angles are very shallow<br/>A good angle to use, but may be difficult to shoot the top key and middle fender | |||

55 degree angle<br/>Precision from any distance is not an issue<br/>The top and middle fender and the top key are impossible shots<br/>Too shallow an angle, entrance velocity may be too high for many shots, causing a rebound | |||

To finish, the 65 degree angle is the best choice for a balance between shot velocity precision and basket entry angle. | |||

= Tasks In Progress = | |||

*Collector | |||

*Finishe<span id="fck_dom_range_temp_1326851844220_866" /><span id="fck_dom_range_temp_1326851844221_694" />d assembly | |||

*made of sheet metal | |||

*put support bar | |||

*did calculations for pneumatic placement and stroke | |||

*did force calc | |||

*completed full ODBAS assembly | |||

*Thank you | |||

*task | *task | ||

= Tasks | = Tasks to Completed = | ||

Discussed pros and cons of different convayer designs | |||

Drew up detailed designes of pneumatic and motorized convayers(pictures to come) | |||

| |||

[http://penfieldrobotics.com/wiki/images/b/b8/Pnumatic_Convayor.JPG http://penfieldrobotics.com/wiki/images/b/b8/Pnumatic_Convayor.JPG] | |||

| |||

[http://penfieldrobotics.com/wiki/images/6/6b/Photo.JPG http://penfieldrobotics.com/wiki/images/6/6b/Photo.JPG] | |||

| |||

Motorized Convayer Pneumatic Convayer | |||

| |||

Materials Needed | |||

*task | *task | ||

**sub-task | **sub-task | ||

**sub-task | **sub-task | ||

*task | *task | ||

Latest revision as of 16:14, 19 January 2012

Start time: 5:00 PM

End time: 10:00 PM

Members present: Alex W, Mike M, Matthieu D, Ciana R, Alex R, Danny S, Molly C, Brianna M, Nick, and others

Members Attending Next Meeting: Lots and lots of people

Tasks Completed

- Shooter Math Model

Conclusions

70 degree is the baseline angle.

Shoots a little high

Cannot accurately shoot from the mid field

It will work in many situations

65 degree angle

Requires moderate precision to shoot in each hoop from midfield and the key

All angle except the top fender will work

A great general use angle

60 degree angle

Does not require much precision to shoot in hoops from any distance

The top key and middle fender angles are very shallow

A good angle to use, but may be difficult to shoot the top key and middle fender

55 degree angle

Precision from any distance is not an issue

The top and middle fender and the top key are impossible shots

Too shallow an angle, entrance velocity may be too high for many shots, causing a rebound

To finish, the 65 degree angle is the best choice for a balance between shot velocity precision and basket entry angle.

Tasks In Progress

- Collector

- Finishe<span id="fck_dom_range_temp_1326851844220_866" /><span id="fck_dom_range_temp_1326851844221_694" />d assembly

- made of sheet metal

- put support bar

- did calculations for pneumatic placement and stroke

- did force calc

- completed full ODBAS assembly

- Thank you

- task

Tasks to Completed

Discussed pros and cons of different convayer designs

Drew up detailed designes of pneumatic and motorized convayers(pictures to come)

http://penfieldrobotics.com/wiki/images/b/b8/Pnumatic_Convayor.JPG

http://penfieldrobotics.com/wiki/images/6/6b/Photo.JPG

Motorized Convayer Pneumatic Convayer

Materials Needed

- task

- sub-task

- sub-task

- task