2017:Fuel and Shooting: Difference between revisions

No edit summary |

No edit summary |

||

| (13 intermediate revisions by 2 users not shown) | |||

| Line 4: | Line 4: | ||

**1/2" solid aluminum hex shaft | **1/2" solid aluminum hex shaft | ||

**center of shaft 5 3/4" high | **center of shaft 5 3/4" high | ||

** | **using an encoder to maintain rotational speed | ||

**RS775 pro motor [http://www.vexrobotics.com/vexpro/motors-electronics/217-4347.html http://www.vexrobotics.com/vexpro/motors-electronics/217-4347.html] | **RS775 pro motor [http://www.vexrobotics.com/vexpro/motors-electronics/217-4347.html http://www.vexrobotics.com/vexpro/motors-electronics/217-4347.html] | ||

***transmissions: | ***transmissions: | ||

| Line 14: | Line 14: | ||

***[[File:5 intake calcs.PNG|RTENOTITLE]] | ***[[File:5 intake calcs.PNG|RTENOTITLE]] | ||

***will potentially use either one, need to test | ***will potentially use either one, need to test | ||

***<font color="#000000" face="sans-serif"><span style="font-size: 12.7px;">lmao :-) intake is the best SuBtEaM ever! lol | ***<font color="#000000" face="sans-serif"><span style="font-size: 12.7px;">lmao :-) intake is the best SuBtEaM ever! lol</span></font> | ||

[[File:Int.PNG|RTENOTITLE]] | |||

[[File:Swa.PNG|RTENOTITLE]] | |||

*<u>'''Shooter'''</u> | *<span style="font-size:large;"><u>'''Shooter'''</u></span> | ||

The balls will come in through the transition and stop at the indexer wheels. When the balls need to be shot, the main shooter wheels will be powered to full speed and then the indexer wheels will feed the balls into the shooter. | |||

*Flex-Grip Drive Rollers for wheels [https://www.mcmaster.com/#catalog/123/1171/=167nss3  https://www.mcmaster.com/#catalog/123/1171/=167nss3 ]; | |||

*2 wheel + 2 rail combo for each shooter | |||

*Dual Input 775 Pros | |||

**4:1 gear ratio | |||

*[[File:Shooter guud meem.PNG|RTENOTITLE]] | |||

| | |||

[[File: | *'''<u><span style="font-size:larger;">Transition</span></u>'''<u><span style="font-size:larger;"><u></u></span></u> | ||

The intake takes in the ball. The first stage of the conveyor, the chicken pluckers located to the bottom right of the intake, are powered individually and spin to move the balls into storage while intaking. The second stage of the conveyor, the conveyor belt which is mechanically linked to the indexer, does not spin until ready to shoot. When the shooter has spun up, the indexer/conveyor moves at the correct speed to move the balls into the shooter (testing is needed to find that speed). There will be an encoder on the motor of the conveyor/indexer system. The first stage of the conveyor may need to spin while shooting in order to ensure balls don't get stuck. A lower priority task is making everything move backwards to resolve possible jams. The shooter may need to move backwards on its own when taking balls from the hopper. | |||

'''<u><span style="font-size:larger;">[[File:Robot Conveyor 2017.PNG|RTENOTITLE]]</span></u>''' | |||

Latest revision as of 14:56, 4 February 2017

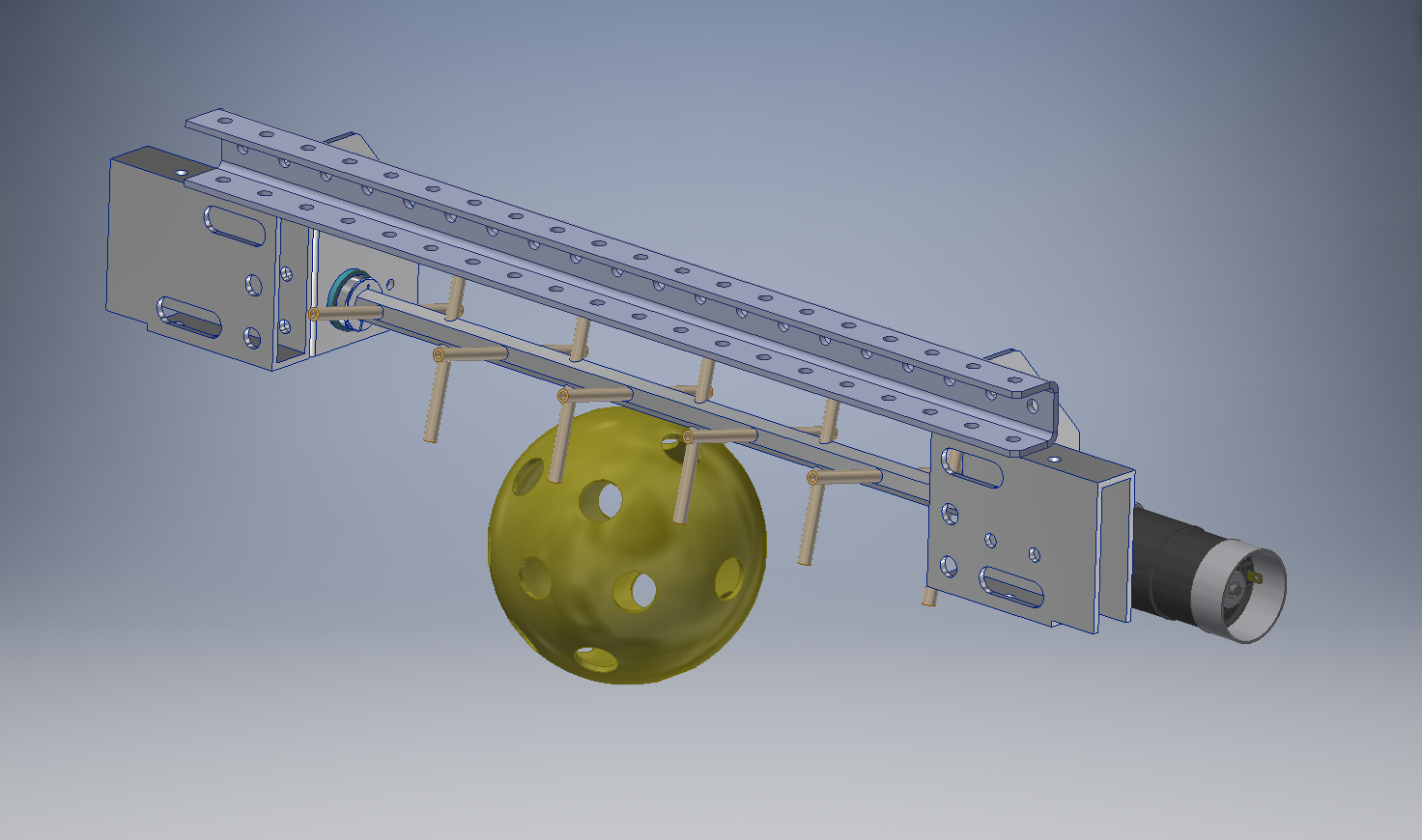

- Intake

- 17" wide opening

- pneumatic tubing chicken pluckers w/ 4" diameter

- 1/2" solid aluminum hex shaft

- center of shaft 5 3/4" high

- using an encoder to maintain rotational speed

- RS775 pro motor http://www.vexrobotics.com/vexpro/motors-electronics/217-4347.html

- Shooter

The balls will come in through the transition and stop at the indexer wheels. When the balls need to be shot, the main shooter wheels will be powered to full speed and then the indexer wheels will feed the balls into the shooter.

- Flex-Grip Drive Rollers for wheels https://www.mcmaster.com/#catalog/123/1171/=167nss3

- 2 wheel + 2 rail combo for each shooter

- Dual Input 775 Pros

- 4:1 gear ratio

- Transition<u></u>

The intake takes in the ball. The first stage of the conveyor, the chicken pluckers located to the bottom right of the intake, are powered individually and spin to move the balls into storage while intaking. The second stage of the conveyor, the conveyor belt which is mechanically linked to the indexer, does not spin until ready to shoot. When the shooter has spun up, the indexer/conveyor moves at the correct speed to move the balls into the shooter (testing is needed to find that speed). There will be an encoder on the motor of the conveyor/indexer system. The first stage of the conveyor may need to spin while shooting in order to ensure balls don't get stuck. A lower priority task is making everything move backwards to resolve possible jams. The shooter may need to move backwards on its own when taking balls from the hopper.