2018:End Game Mechanism: Difference between revisions

Drivetrain (talk | contribs) No edit summary |

Programming (talk | contribs) No edit summary |

||

| (58 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

== | <div class="mw-parser-output"> | ||

<span style="font-size:medium">'''Subteam Leads:''' Mark M, Tai L, Rachel B</span> | |||

= Current Design Information = | |||

* '''''Things we need to document here''''': | |||

** Any picture/sketch of the overall design would go a long way for understanding! | |||

** How are the ramps held inside the robot starting config? | |||

** How are they deployed (conceptually and mechanically - what actions or actuations??) Do cube mechanism parts need to be put in any specific state beforehand? | |||

** How are they controlled once deployed? What's driving those scissor jacks/lifts? | |||

** What is the range of travel on the scissor lift of the ramp? | |||

** What happens if it goes too far? | |||

** How do we know how far we've gone? | |||

** Will the lifts back-drive under load of partner robots? If so, what holds them at position? | |||

** What actuators are being used and what do they control?? | |||

< | <div class="mw-parser-output"> | ||

<div class="mw-parser-output"> | |||

<div class="mw-parser-output"> | |||

<div class="mw-parser-output"> | |||

<div class="mw-parser-output"> | |||

<div class="mw-parser-output"> | |||

<div class="mw-parser-output"> | |||

<div class="mw-parser-output"> | |||

<div class="mw-parser-output"> | |||

= Meeting Journal = | |||

<span style="font-size:medium | '''<u><span style="font-size:medium">Day 1</span></u>>>>''' | ||

<span style="font-size: medium | <span style="font-size:medium">Brainstormed concepts of how to climb: </span> | ||

<span style="font-size: medium | <span style="font-size: medium">Use climbing mechanism that will be able to share bar with another robot</span> | ||

<span style="font-size: medium | <span style="font-size: medium">Use climbing mechanism that will take up entire bar but will take another robot up with ours</span> | ||

<span style="font-size: medium">Create our own ramp that will lift up both robots above 11"</span> | |||

<span style="font-size:medium | <font size="3">Made sure our brainstormed designs would account for bumper rules ( </font><span style="font-size: medium"><span id="docs-internal-guid-95a47d18-f175-5721-b935-d5f6de61959b"><span style="font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">We realized that prototypes that drop below our drivetrain violate the bumper rules. The bumper rule states</span></span></span> | ||

<span style="font-size:medium;">- Two ramps | <span style="font-size:medium"><span style="font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">R24. BUMPERS must be located entirely within the BUMPER ZONE, which is the volume contained between the floor and a virtual horizontal plane 7 in. (~17 cm) above the floor in reference to the ROBOT standing normally on a flat floor. BUMPERS do not have to be parallel to the floor. This measurement is intended to be made as if the ROBOT is resting on a flat floor (without changing the ROBOT configuration), not relative to the height of the ROBOT from the FIELD carpet. Examples include: Example 2: A ROBOT deploys a MECHANISM which lifts the BUMPERS outside the BUMPER ZONE (when virtually transposed onto a flat floor). This violates R24)</span></span> <span style="font-size:medium">- Two ramps fold down, one end being fixed at around 11" above the platfrom and other end starting on the carpet, carpet end would raise up to around 11"</span> | ||

<span style="font-size: medium | <span style="font-size:medium">- Two ramps fold down, most of ramp is parallel and 11" above platform and at the end, it folds down at the same angle of the edge of the platform</span> | ||

<span style="font-size:medium;">- Two ramps fold out like a butterfly (folds twice), first fold will have top of ramp at 11" above platform, would be 33" by 33", and second fold will extend down to the carpet where robots can drive up it </span> | <span style="font-size: medium">- Same as first concept, except rather than having ramp start at carpet, it would start at the top edge of the platform</span> | ||

<span style="font-size:medium">- Two ramps fold out like a butterfly (folds twice), first fold will have top of ramp at 11" above platform, would be 33" by 33", and second fold will extend down to the carpet where robots can drive up it </span> | |||

<font size="3">- Use a climbing mechanism that would take up entire bar but would be able to take another robot up with us</font> | <font size="3">- Use a climbing mechanism that would take up entire bar but would be able to take another robot up with us</font> | ||

| Line 31: | Line 52: | ||

<font size="3">- Have bar on bottom of robot, would have another robtot connect on bottom after we are all the way up</font> | <font size="3">- Have bar on bottom of robot, would have another robtot connect on bottom after we are all the way up</font> | ||

'''<u><span style="font-size:medium">Day 2</span></u><span style="font-size:medium">>>></span>''' | |||

<font size="3">Realized ramp idea would be safer than climbing up, especially with other robots</font> | |||

<span style="font-size:medium">Designed several different concepts for a ramp</span> | |||

<span style="font-size:medium">Tested measurements and variables for the ramp <span id="docs-internal-guid-95a47d18-f175-5721-b935-d5f6de61959b"><span style="font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">(Angle tests: 13 15 20 25,</span></span><span id="docs-internal-guid-95a47d18-f175-5721-b935-d5f6de61959b"><span style="font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Tests were worst case scenarios with 4 inch omni wheels and bumpers with 1.5 inch clearance.)</span></span></span> | |||

<font color="#000000" face="Arial" size="3"><span style="white-space: pre-wrap">Started to lean more towards building a ramp for other robots to drive up</span></font> | |||

| |||

'''<u><span style="font-size:medium">Day 3</span></u><span style="font-size:medium">>>></span>''' | |||

<span style="font-size:medium">Started building carboard prototypes</span> | |||

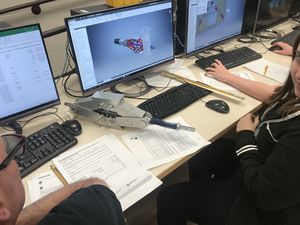

<span style="font-size:medium">Started putting concepts on CAD</span> | |||

<span style="font-size:medium | <span style="font-size:medium">Realized that Null Zone will interefere with the ramp design (</span><span style="color: rgb(0, 0, 0); font-family: Arial; font-size: medium; white-space: pre-wrap">Continued evaluation of the game by strategy revealed that it is possible for an opponent to defend one of our partners from getting on our ramp. If the opponent is touching their null zone they would completely block access to that side of our ramp. Because of this Strategy has given us the following criteria. Ramps must be accessed by robots from the platform zone.)</span> | ||

<font size | <span style="font-size:medium">Began to think of how we would actuate certain designs ( Thinking about using pneumatics, car jacks)</span> | ||

<span style="font-size:medium | '''<span style="font-size:medium"><u>Day 4 </u>>>></span>''' | ||

<span style="font-size:medium | <span style="font-size:medium">Narrowed down to 2 ramp designs</span>: | ||

<span style="font-size:medium">- One design had a side fixed at 11" with a hinge and the other side would rise up with some type of actuator</span> | |||

<font size="3">- The other design would have two plates flat on the platform that the robots would drive up on and then the plates would rise up like an elevator</font> | |||

| |||

< | '''<span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; text-decoration-line: underline; vertical-align: baseline; white-space: pre-wrap">Day 5 </span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">>>></span></span>''' | ||

<span style="font-size: | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Started buildings design with foam core</span></span> | ||

<span style="font-size: | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Were able to find out final dimensions with drive team base</span></span> | ||

<span | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Finished CAD prototyping</span></span> | ||

<span style="font-size: | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Prepared speech for Saturday objective tables</span></span> | ||

<span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">-Develop best concept</span></span> | |||

<span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap"> </span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Fit within space allowed</span></span> | |||

< | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">-Ability to be consistent</span></span> | ||

<span style="font-size: | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">- Meet weight requirement</span></span> | ||

<span style="font-size: | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">-Able to account for other teams robots</span></span> | ||

<font size | <span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">-That we can fit it into our own</span></span> | ||

<span id="docs-internal-guid-95a47d18-f1be-362b-1c4e-67277fd6e995"><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">-Buildible</span></span> | |||

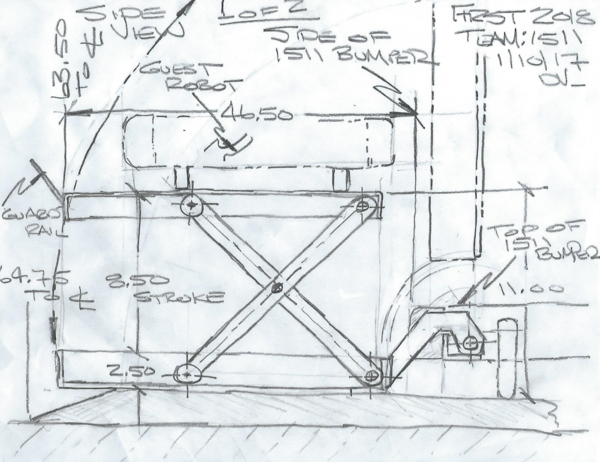

<u><span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Lift Concept Side View</span></span></u> | |||

<span style="font-size:medium"><span style="background-color:#00FF00">Check out the POC Video of this Concept on Day 7:</span></span> | |||

| |||

<span | <span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">[[File:Lift concept side view.png|border|600x600px|Lift concept side view]]</span></span> | ||

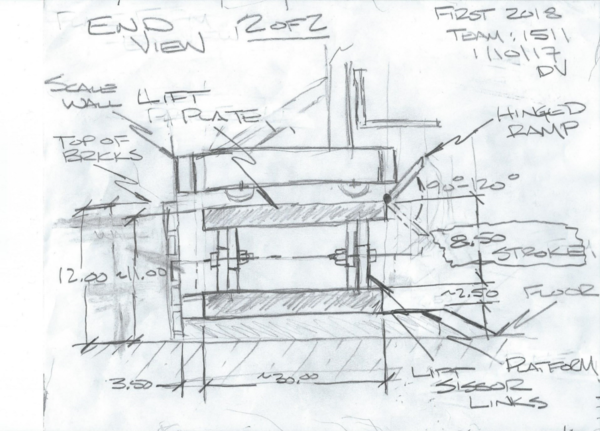

<span | <u><span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Lift Concept End View</span></span></u> | ||

<span | <span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">[[File:Lift Concept End View.png|border|600x600px|Lift Concept End View.png]]</span></span> | ||

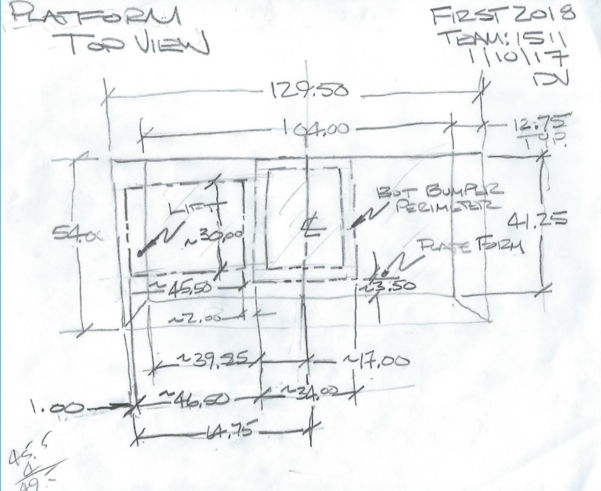

<span | <u><span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">Lift Concept Plan View</span></span></u> | ||

<span | <span><span style="font-size: 12pt; font-family: Arial; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; vertical-align: baseline; white-space: pre-wrap">[[File:Lift Concept Plan View.png|border|601x601px|Lift Concept Plan View.png]]</span></span> | ||

| |||

'''<span style="font-size:medium"><u>Day 6</u>>>></span>''' | |||

<span style="font-size:medium">Weighted objective tables for which mechanism we would use ( Either the elevator or the hinge)</span> | |||

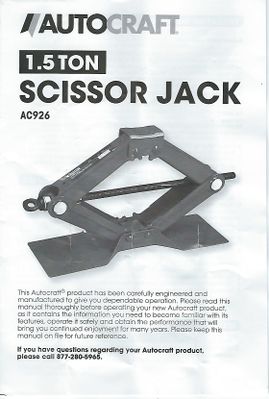

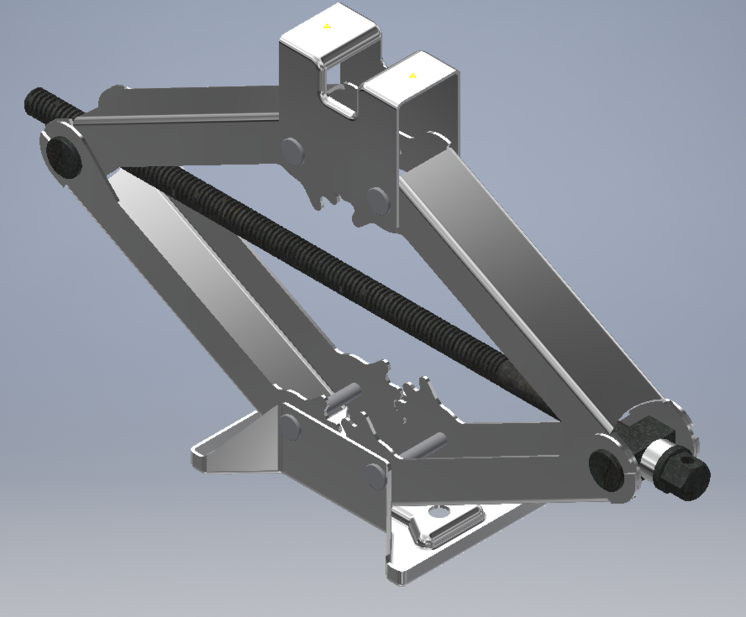

<span style="font-size:medium">Look at possibly using a Sissors Jack Mechanism for the lift... obtained a AutoCraft AC926 Scissor Jack to experiment and analyze its capabilities.</span> | |||

<span style="font-size:medium">[[File:AC926 Jack.jpg|400x400px|AC926 Jack.jpg]]</span> | |||

| |||

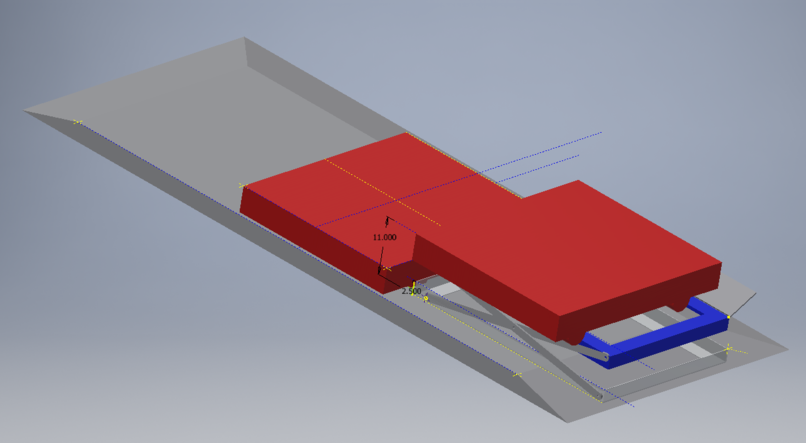

<span style="font-size:medium">CAD of our concept with actual measurements</span> | |||

<span style="font-size:medium | |||

[[File:Lift.PNG|822x443px|Lift.PNG]] | |||

<font size="3">Started to CAD the car jack for our lift</font> | <font size="3">Started to CAD the car jack for our lift</font> | ||

[[File:Car jack.PNG|746x618px|RTENOTITLE]] | |||

| |||

'''<u><span style="font-size:medium">Day 7 (11/14/2018 )</span></u><span style="font-size:medium">>>></span>''' | |||

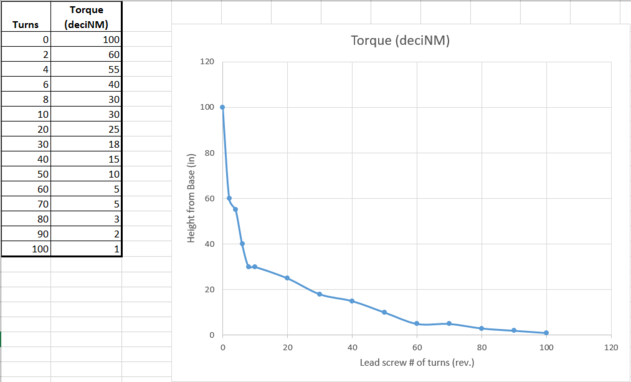

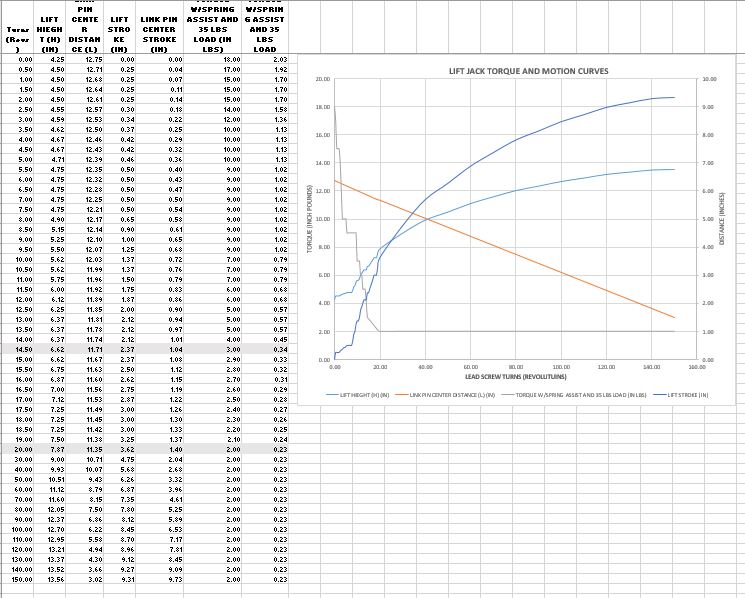

<span style="font-size:medium">AC926 Scissor Jack Torque Curve</span> | |||

[[File:Torque curve.PNG|631x382px|RTENOTITLE]] | |||

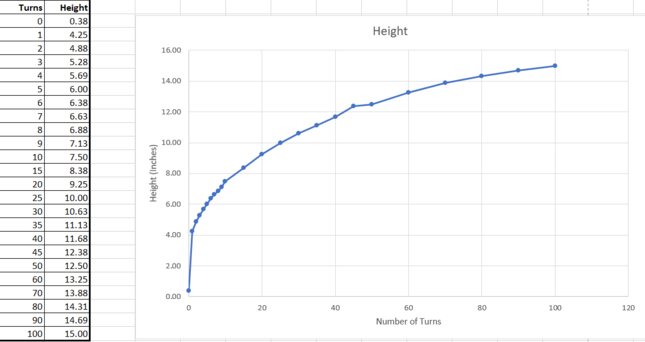

<span style="font-size:medium | <span style="font-size:medium">AC926 Scissor Jack Motion Curve</span> | ||

[[File:Height curve.PNG|645x342px|RTENOTITLE]] | |||

| |||

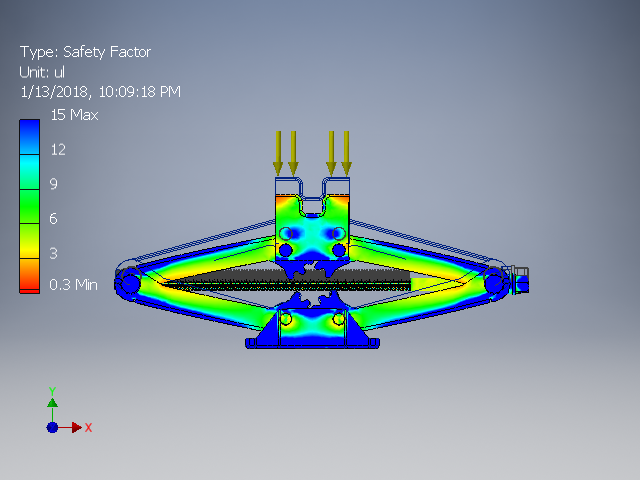

<span style="font-size:medium">Aluminum Jack load analysis</span> | |||

[[File:Result 0 57.png|RTENOTITLE]] | |||

<span style="font-size:medium">Car jack can hold 650 lbs with 0.1 inches of deflection</span> | |||

<span style="font-size:medium">This is the torque and motions curve for the final production model lift jack with a 35 pound lift load applied</span> | |||

<span style="font-size:medium">[[File:Production Lift Jack Motion and Torque Curves.JPG|RTENOTITLE]]</span> | |||

[[File: | <u><span style="font-size:medium">1511 2018 Robot Lift POC Video</span></u> | ||

<u><span style="font-size:medium">Click to View Video:</span></u>[[Media:1511_2018_Robot_Lift_POC_Videp_01142018.zip]] | |||

<span style="font-size:medium">[[File:1511 2018 Robot Lift POC Video Thumb nail Image 01142018.png|618x347px|1511 2018 Robot Lift POC Video Thumb nail Image 01142018.png]]</span>.. | |||

| |||

| |||

<u><span style="font-size:medium">Potential Lift Drive Motor and Gear Box</span></u> | |||

<span style="font-size:medium">Vex 775 Pro Motor: [https://www.vexrobotics.com/versaplanetary.html https://www.vexrobotics.com/versaplanetary.html]</span> | |||

<span style="font-size:medium">Vex Planetary Gear Box: [https://www.vexrobotics.com/217-4347.html https://www.vexrobotics.com/217-4347.html]</span> | |||

<span style="font-size:medium">Vex 775 Pro Motor Spec:</span>[http://motors.vex.com/vexpro-motors/775pro <span style="font-size:medium">http://motors.vex.com/vexpro-motors/775pro</span>] | |||

| |||

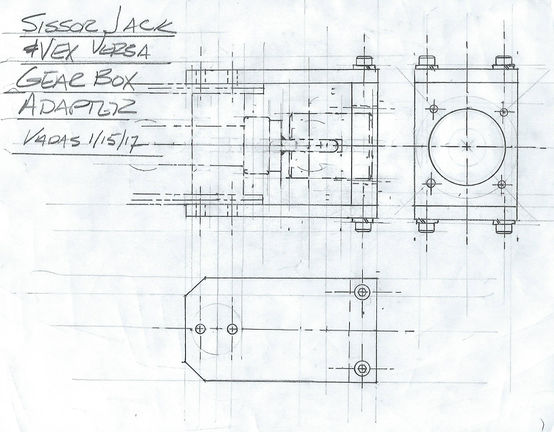

<u><span style="font-size:medium">POC Adapter</span></u> | |||

[[File:Sissor Jack Vex Versa Gear Box Adapter.jpg|618x432px|Sissor Jack Vex Versa Gear Box Adapter.jpg]] | |||

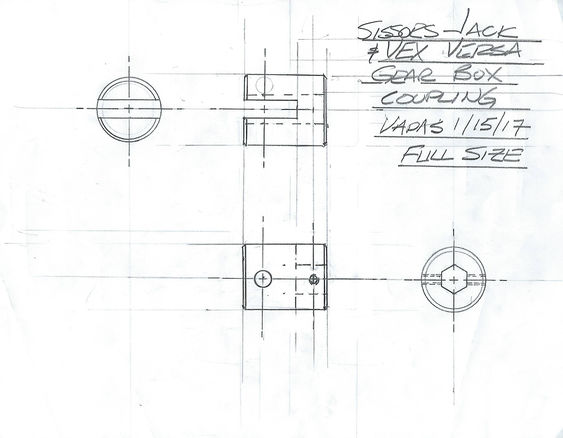

<u><span style="font-size:medium">POC Coupling</span></u> | |||

[[File:Sissor Jack Versa Gear Box Coupling.jpg|border|620x438px|Sissor Jack Versa Gear Box Coupling.jpg]] | |||

<u><span style="font-size:medium">POC AC926 Jack</span></u> | |||

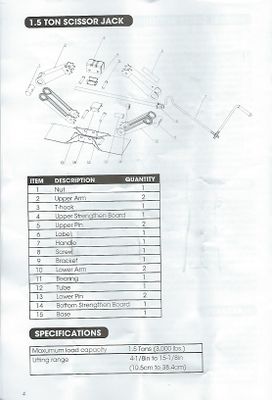

<span style="font-size:medium">[[File:AC926 Jack Assembly Exploded Parts List.jpg|border|400x400px|AC926 Jack Assembly Exploded Parts List.jpg]]</span> | |||

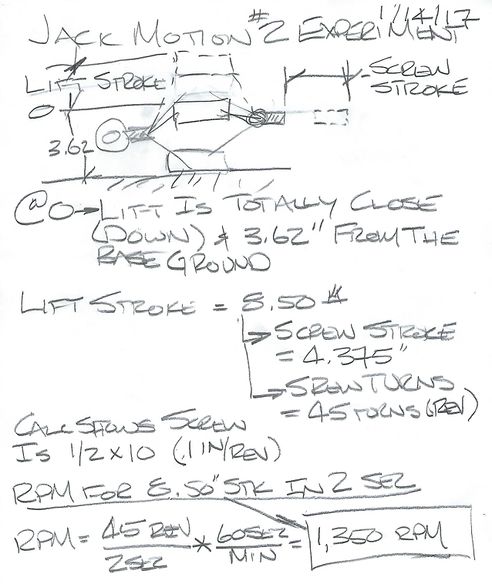

<u><span style="font-size:medium">AC926 Jack Motion Analysis</span></u> | |||

<span style="font-size:medium">[[File:AC926 Jack Experiment.jpg|border|585x585px|AC926 Jack Experiment.jpg]]</span> | |||

<u><span style="font-size:medium">Day 8</span></u> | |||

<span style="font-size:medium">-Springloading the car jack</span> | |||

<span style="font-size:medium">-Making part files for each part of the car jack</span> | |||

<span style="font-size:medium">- Began making Harris shop drawings tor car jack parts</span> | |||

[[File:AC926 with Spring Assist.JPG|500px|AC926 with Spring Assist.JPG]] | |||

<span style="font-size:medium"><u>Day 9</u></span> | |||

<span style="font-size:medium">-Working on scissor jack assembly in CAD</span> | |||

<span style="font-size:medium">-Tapping holes on car jack to allow for better spring loading</span> | |||

<span style="font-size:medium">-</span> | |||

<span style="font-size:medium"><u>1/21/2018</u></span> | |||

<span style="font-size:medium">-Weighed lead screw for jack. They weigh 0.9 lbs.</span> | |||

<u><span style="font-size:medium">1/31/2018</span></u> | |||

<u><span style="font-size:medium">[https://photos.app.goo.gl/ToQFIZLOpAJ6nvlt1 https://photos.app.goo.gl/ToQFIZLOpAJ6nvlt1]</span></u> To view the jack test click the link. | |||

[[File:IMG 0546.JPG|300px|IMG 0546.JPG]] | |||

| |||

Overall Ramp: 36" x 25.375" x 2<br/> Overall Ramp (ft): 3' x 2.114' x 2<br/> Overall Area (ft): 12.684'<br/> 1/4" Thickness Weight: 0.79 lb/ft2<br/> 1/2" Thickness Weight: 0.84 lb/ft2<br/> 3/4" Thickness Weight: 0.94 lb/ft2<br/> 1/4" Overall Weight (lbs): 10.020 lbs<br/> 1/2" Overall Weight (lbs): 10.654 lbs<br/> 3/4" Overall Weight (lbs): 11.922 lbs | |||

1/4" Overall Weight Actual with cutouts (lbs): 7.84312 lbs | |||

<span style="font-size:medium"><u>2/14/2018 - Valentines Day</u></span> | |||

<span style="font-size:medium">Production Lift Jack Serial Number LJ02 - Total Weight 4.61 Lbs.</span> | |||

[[File:LiftJackProd SSN LJ02.jpg|400x400px|LiftJackProd SSN LJ02.jpg]] | |||

This is not what our lifts actually look like | |||

<span style="font-size:medium | '''''<u><span style="font-size:medium">Tons of usefull reference links below</span></u><span style="font-size:medium">>>></span>''''' | ||

=== putting together a 14-1 gear ratio motor === | === putting together a 14-1 gear ratio motor: === | ||

<span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://www.etrailer.com/Vehicle-Suspension/SuperSprings/SSF-102-47.html?feed=npn&gclid=EAIaIQobChMI1vLSnsjM2AIVS7nACh1mGADbEAYYAyABEgIGBvD_BwE&hmac=f1f238ddb0d7fd8eb9e4abfe13354228 http://www.flexicraft.com/Rubber_Expansion_Joints]</span> | <span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://www.etrailer.com/Vehicle-Suspension/SuperSprings/SSF-102-47.html?feed=npn&gclid=EAIaIQobChMI1vLSnsjM2AIVS7nACh1mGADbEAYYAyABEgIGBvD_BwE&hmac=f1f238ddb0d7fd8eb9e4abfe13354228 http://www.flexicraft.com/Rubber_Expansion_Joints]</span> | ||

| Line 146: | Line 271: | ||

<span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://grabcad.com/library&hmac=a6d1d428fa2f755dc8d138f1694d3bc8 https://grabcad.com/library]</span> | <span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://grabcad.com/library&hmac=a6d1d428fa2f755dc8d138f1694d3bc8 https://grabcad.com/library]</span> | ||

<span style="font-size: 12pt">2010 Breakaway</span> | <span style="font-size: 12pt">2010 Breakaway</span> | ||

| Line 160: | Line 281: | ||

<span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://youtu.be/OmZhu_vJV1M&hmac=e52fc76a5d9e0d565aaf22132fdcfdec https://youtu.be/OmZhu_vJV1M]</span> | <span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://youtu.be/OmZhu_vJV1M&hmac=e52fc76a5d9e0d565aaf22132fdcfdec https://youtu.be/OmZhu_vJV1M]</span> | ||

<span style="font-size: 12pt">Team 118 Robonauts</span> | <span style="font-size: 12pt">Team 118 Robonauts</span> | ||

| Line 185: | Line 304: | ||

<span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://www.onlinemetals.com/merchant.cfm?id=62&step=2&top_cat=60&hmac=2d38e82123dc7139efce89f18d9eb4d9 https://www.onlinemetals.com/merchant.cfm?id=62&step=2&top_cat=60]</span> | <span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://www.onlinemetals.com/merchant.cfm?id=62&step=2&top_cat=60&hmac=2d38e82123dc7139efce89f18d9eb4d9 https://www.onlinemetals.com/merchant.cfm?id=62&step=2&top_cat=60]</span> | ||

<span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://www.plascore.com/honeycomb/honeycomb-panels/standard-honeycomb-panels/&hmac=6cbcf208b78c8efcb3552b0d5affc389 https://www.plascore.com/honeycomb/honeycomb-panels/standard-honeycomb-panels/]</span> | <span style="font-size: 12pt">[https://mail.twc.com/do/redirect?url=https://www.plascore.com/honeycomb/honeycomb-panels/standard-honeycomb-panels/&hmac=6cbcf208b78c8efcb3552b0d5affc389 https://www.plascore.com/honeycomb/honeycomb-panels/standard-honeycomb-panels/]</span> </div> </div> </div> </div> </div> </div> </div> </div> | ||

< | [https://photos.app.goo.gl/TpJkiIEmcg0JgyG43 https://photos.app.goo.gl/TpJkiIEmcg0JgyG43] - photos of Shaker Robotics Lifts/ Robot from 2018 CNY Regional </div> | ||

</div> | |||

Latest revision as of 15:10, 12 December 2018

Subteam Leads: Mark M, Tai L, Rachel B

Current Design Information

- Things we need to document here:

- Any picture/sketch of the overall design would go a long way for understanding!

- How are the ramps held inside the robot starting config?

- How are they deployed (conceptually and mechanically - what actions or actuations??) Do cube mechanism parts need to be put in any specific state beforehand?

- How are they controlled once deployed? What's driving those scissor jacks/lifts?

- What is the range of travel on the scissor lift of the ramp?

- What happens if it goes too far?

- How do we know how far we've gone?

- Will the lifts back-drive under load of partner robots? If so, what holds them at position?

- What actuators are being used and what do they control??

Meeting Journal

Day 1>>>

Brainstormed concepts of how to climb:

Use climbing mechanism that will be able to share bar with another robot

Use climbing mechanism that will take up entire bar but will take another robot up with ours

Create our own ramp that will lift up both robots above 11"

Made sure our brainstormed designs would account for bumper rules ( We realized that prototypes that drop below our drivetrain violate the bumper rules. The bumper rule states

R24. BUMPERS must be located entirely within the BUMPER ZONE, which is the volume contained between the floor and a virtual horizontal plane 7 in. (~17 cm) above the floor in reference to the ROBOT standing normally on a flat floor. BUMPERS do not have to be parallel to the floor. This measurement is intended to be made as if the ROBOT is resting on a flat floor (without changing the ROBOT configuration), not relative to the height of the ROBOT from the FIELD carpet. Examples include: Example 2: A ROBOT deploys a MECHANISM which lifts the BUMPERS outside the BUMPER ZONE (when virtually transposed onto a flat floor). This violates R24) - Two ramps fold down, one end being fixed at around 11" above the platfrom and other end starting on the carpet, carpet end would raise up to around 11"

- Two ramps fold down, most of ramp is parallel and 11" above platform and at the end, it folds down at the same angle of the edge of the platform

- Same as first concept, except rather than having ramp start at carpet, it would start at the top edge of the platform

- Two ramps fold out like a butterfly (folds twice), first fold will have top of ramp at 11" above platform, would be 33" by 33", and second fold will extend down to the carpet where robots can drive up it

- Use a climbing mechanism that would take up entire bar but would be able to take another robot up with us

- Use a climbing mechanism that would be small enough to share bar with another robot

- Have bar on bottom of robot, would have another robtot connect on bottom after we are all the way up

Day 2>>>

Realized ramp idea would be safer than climbing up, especially with other robots

Designed several different concepts for a ramp

Tested measurements and variables for the ramp (Angle tests: 13 15 20 25,Tests were worst case scenarios with 4 inch omni wheels and bumpers with 1.5 inch clearance.)

Started to lean more towards building a ramp for other robots to drive up

Day 3>>>

Started building carboard prototypes

Started putting concepts on CAD

Realized that Null Zone will interefere with the ramp design (Continued evaluation of the game by strategy revealed that it is possible for an opponent to defend one of our partners from getting on our ramp. If the opponent is touching their null zone they would completely block access to that side of our ramp. Because of this Strategy has given us the following criteria. Ramps must be accessed by robots from the platform zone.)

Began to think of how we would actuate certain designs ( Thinking about using pneumatics, car jacks)

Day 4 >>>

Narrowed down to 2 ramp designs:

- One design had a side fixed at 11" with a hinge and the other side would rise up with some type of actuator

- The other design would have two plates flat on the platform that the robots would drive up on and then the plates would rise up like an elevator

Day 5 >>>

Started buildings design with foam core

Were able to find out final dimensions with drive team base

Finished CAD prototyping

Prepared speech for Saturday objective tables

-Develop best concept

Fit within space allowed

-Ability to be consistent

- Meet weight requirement

-Able to account for other teams robots

-That we can fit it into our own

-Buildible

Lift Concept Side View

Check out the POC Video of this Concept on Day 7:

Lift Concept End View

Lift Concept Plan View

Day 6>>>

Weighted objective tables for which mechanism we would use ( Either the elevator or the hinge)

Look at possibly using a Sissors Jack Mechanism for the lift... obtained a AutoCraft AC926 Scissor Jack to experiment and analyze its capabilities.

CAD of our concept with actual measurements

Started to CAD the car jack for our lift

Day 7 (11/14/2018 )>>>

AC926 Scissor Jack Torque Curve

AC926 Scissor Jack Motion Curve

Aluminum Jack load analysis

Car jack can hold 650 lbs with 0.1 inches of deflection

This is the torque and motions curve for the final production model lift jack with a 35 pound lift load applied

1511 2018 Robot Lift POC Video

Click to View Video:Media:1511_2018_Robot_Lift_POC_Videp_01142018.zip

Potential Lift Drive Motor and Gear Box

Vex 775 Pro Motor: https://www.vexrobotics.com/versaplanetary.html

Vex Planetary Gear Box: https://www.vexrobotics.com/217-4347.html

Vex 775 Pro Motor Spec:http://motors.vex.com/vexpro-motors/775pro

POC Adapter

POC Coupling

POC AC926 Jack

AC926 Jack Motion Analysis

Day 8

-Springloading the car jack

-Making part files for each part of the car jack

- Began making Harris shop drawings tor car jack parts

Day 9

-Working on scissor jack assembly in CAD

-Tapping holes on car jack to allow for better spring loading

-

1/21/2018

-Weighed lead screw for jack. They weigh 0.9 lbs.

1/31/2018

https://photos.app.goo.gl/ToQFIZLOpAJ6nvlt1 To view the jack test click the link.

Overall Ramp: 36" x 25.375" x 2

Overall Ramp (ft): 3' x 2.114' x 2

Overall Area (ft): 12.684'

1/4" Thickness Weight: 0.79 lb/ft2

1/2" Thickness Weight: 0.84 lb/ft2

3/4" Thickness Weight: 0.94 lb/ft2

1/4" Overall Weight (lbs): 10.020 lbs

1/2" Overall Weight (lbs): 10.654 lbs

3/4" Overall Weight (lbs): 11.922 lbs

1/4" Overall Weight Actual with cutouts (lbs): 7.84312 lbs

2/14/2018 - Valentines Day

Production Lift Jack Serial Number LJ02 - Total Weight 4.61 Lbs.

This is not what our lifts actually look like

Tons of usefull reference links below>>>

putting together a 14-1 gear ratio motor:

http://www.flexicraft.com/Rubber_Expansion_Joints

http://www.enidine.com/en-US/Products/AirSprings/

R10LAM&ust=1515646785440859

https://www.enerpac.com/en/news/new-ultra-flat-hydraulic-cylinders

http://www.ergo-help.net/telescoping-air-cylinders.html

https://grabcad.com/library/manual-mini-scissor-lift-1

https://grabcad.com/naren-15/projects

2010 Breakaway

Team 118 Robonauts

https://youtu.be/PtRewwr59d8 - Team 118's robot for the 2014 FIRST Robotics Competition

https://youtu.be/sWHwDfpeYjo - firing winch hanger

https://youtu.be/sWHwDfpeYjo - Extending grabbing arm

FRC Team #971 Spartan Robotics

https://youtu.be/F_Auxy_ZdAQ - Good vertical lift FRC Team #971 Spartan Robotics

Cheif Delphi - How will your robot hand

https://www.chiefdelphi.com/forums/showthread.php?threadid=161014

https://www.onlinemetals.com/merchant.cfm?id=62&step=2&top_cat=60

https://www.plascore.com/honeycomb/honeycomb-panels/standard-honeycomb-panels/