2011:Mechanical 2 2.22: Difference between revisions

Mechanical2 (talk | contribs) No edit summary |

Mechanical2 (talk | contribs) No edit summary |

||

| Line 11: | Line 11: | ||

= Tasks to Complete = | = Tasks to Complete = | ||

Washington | Washington Thursday | ||

1 Full system check. | 1. Full system check. | ||

<br> | |||

2. Manupulator exchange. | |||

2 Manupulator exchange. | |||

Evaluate the six nuts and bolts that hold the Wrist to the Arm to see if larger ones can replace the existing.<br>If needed. Prepair the larger nuts and bolts before disassembeling anything. Lock nuts or lock washers or locktight will be needed.<br>Select a clearance drill for the bolts that will be used and chuck into a drill.<br>Mark the shims that are between the Wrist Arm Side and the Arm so that you can tell Robot Right from Robot Left and Front from Back.<br>Disconnect all wires and carefully pull them away from wrist area.<br>Remove six nuts and bolts from Wrist Arm Side and save.<br>Carefull remove Manipulator #1 from arm and keep track of shims (Place them in a preplanned positon).<br>Use the shims to draw the hole pattern on Manipulator #2, be extreemly carefull to keep the orientation correct.<br>Use the drawn holes to "transfer" holes to the new manipulator. | Evaluate the six nuts and bolts that hold the Wrist to the Arm to see if larger ones can replace the existing.<br>If needed. Prepair the larger nuts and bolts before disassembeling anything. Lock nuts or lock washers or locktight will be needed.<br>Select a clearance drill for the bolts that will be used and chuck into a drill.<br>Mark the shims that are between the Wrist Arm Side and the Arm so that you can tell Robot Right from Robot Left and Front from Back.<br>Disconnect all wires and carefully pull them away from wrist area.<br>Remove six nuts and bolts from Wrist Arm Side and save.<br>Carefull remove Manipulator #1 from arm and keep track of shims (Place them in a preplanned positon).<br>Use the shims to draw the hole pattern on Manipulator #2, be extreemly carefull to keep the orientation correct.<br>Use the drawn holes to "transfer" holes to the new manipulator. | ||

| Line 25: | Line 25: | ||

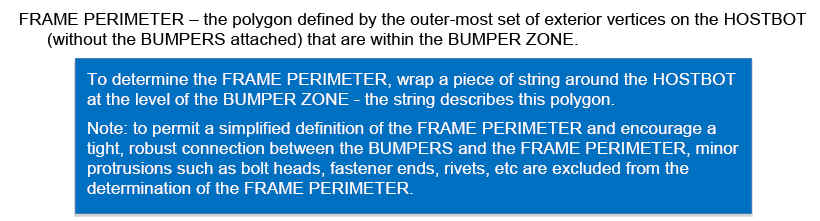

[[Image:2011-03-21.jpg]]<br>So where our frame "sunk in" during welding does not count.<br>It's a straight line from corner to corner projected vertically that determines the frame perimeter.<br> | [[Image:2011-03-21.jpg]]<br>So where our frame "sunk in" during welding does not count.<br>It's a straight line from corner to corner projected vertically that determines the frame perimeter.<br> | ||

3. Driver practice and matches. | |||

4. Minibot nest exchange evaluation and prep work. | |||

<br> | |||

<br> | |||

<br> | |||

<br> | |||

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX | |||

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX | |||

At FLR | At FLR | ||

Revision as of 14:18, 21 March 2011

Attendance

Start time:

End time:

Members present:

Members Attending Next Meeting:

Tasks to Complete

Washington Thursday

1. Full system check.

2. Manupulator exchange.

Evaluate the six nuts and bolts that hold the Wrist to the Arm to see if larger ones can replace the existing.

If needed. Prepair the larger nuts and bolts before disassembeling anything. Lock nuts or lock washers or locktight will be needed.

Select a clearance drill for the bolts that will be used and chuck into a drill.

Mark the shims that are between the Wrist Arm Side and the Arm so that you can tell Robot Right from Robot Left and Front from Back.

Disconnect all wires and carefully pull them away from wrist area.

Remove six nuts and bolts from Wrist Arm Side and save.

Carefull remove Manipulator #1 from arm and keep track of shims (Place them in a preplanned positon).

Use the shims to draw the hole pattern on Manipulator #2, be extreemly carefull to keep the orientation correct.

Use the drawn holes to "transfer" holes to the new manipulator.

Measure the manipulator position relative to the Frame Perimiter. Remember the frame perimiter is ………..

Remember the frame perimiter is;

So where our frame "sunk in" during welding does not count.

It's a straight line from corner to corner projected vertically that determines the frame perimeter.

3. Driver practice and matches.

4. Minibot nest exchange evaluation and prep work.

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

At FLR

1 Put bolts in the corners of the upper structure

2 Put on chain guard

3 Put on minibot roof

Before FLR

1 Order spare parts from Harris

2 Redesign manipulator wheel shafts for maintainability

3 Design chain guard

4 Design manipulator wheel guard

5 Design minibot roof and backstop

Complete;

1 Order McmasterCarr parts

Materials Needed

- task

- sub-task

- sub-task

- task

- 1- Spring load top and bottom

2- Remove corner from top for park position

3- Chain

4- 2 half per side

5- 1 ¾ wrist

6- Skid plate

7- Sensor field of view

8- hard stops open and closed

9- Add bumper to keep tube out of corners

10- stronger wrist

2737T102 12 teeth 3/8 id