2014:Shooter Subteam: Difference between revisions

From 1511Wookiee

Jump to navigationJump to search

No edit summary |

|||

| Line 84: | Line 84: | ||

*Still working on Fundamentals for design | *Still working on Fundamentals for design | ||

*Calculating how far the kicker has to move | |||

* Calculating if motor driven is possible for Kicker | |||

*Calculating if motor driven is possible for Kicker | |||

*met with collection | *met with collection | ||

| Line 98: | Line 99: | ||

*How to stop kicker motion | *How to stop kicker motion | ||

* nylon strap | |||

* blocking plate | |||

*blocking plate | |||

== End of Day Design == | == End of Day Design == | ||

Revision as of 11:38, 19 January 2014

To do

To Be Done

- Finish design for Ball constraint in kicker

- Find where we need mechanical stops

- Raise battery

- Locate kicker stop

- Clearance for electrical

- Area (Bottom Pan for electrical between motors

- Side Restraints

Conflicts

- Kicker path and D.T. stabilizers

Design Analysis

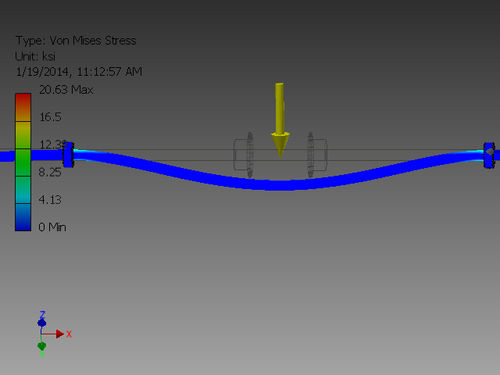

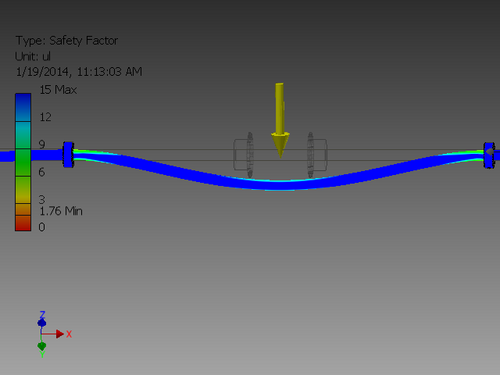

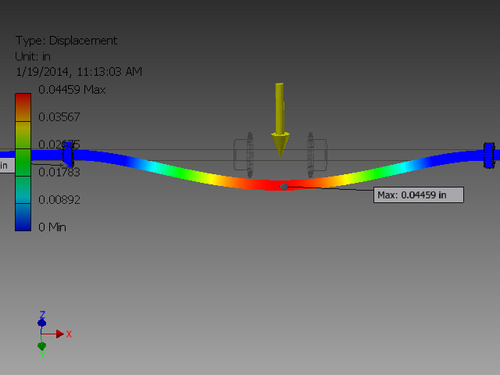

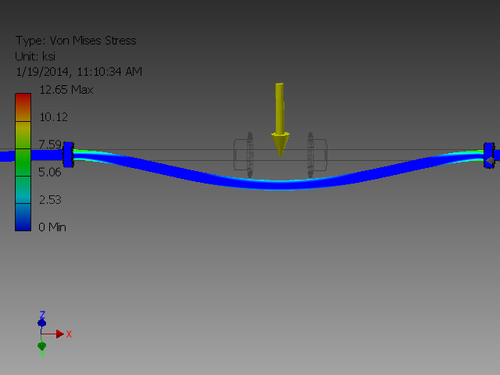

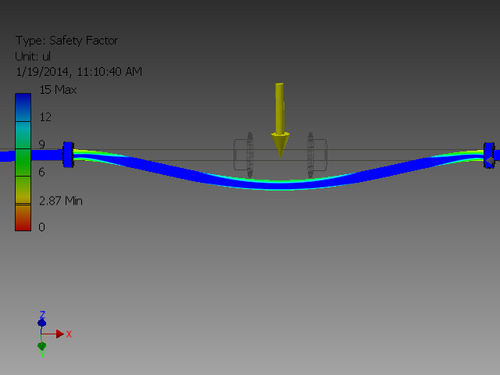

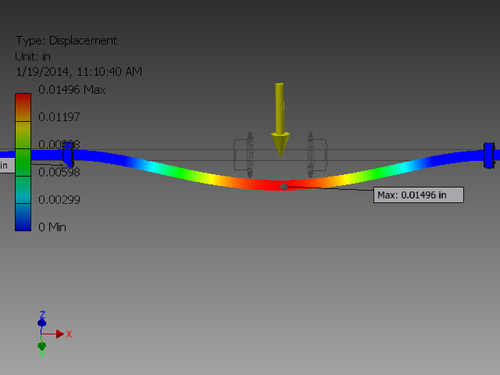

Stress Analysis

- An alumninum rod fixed where the bearings are

- A steel rod fixed where the bearings are

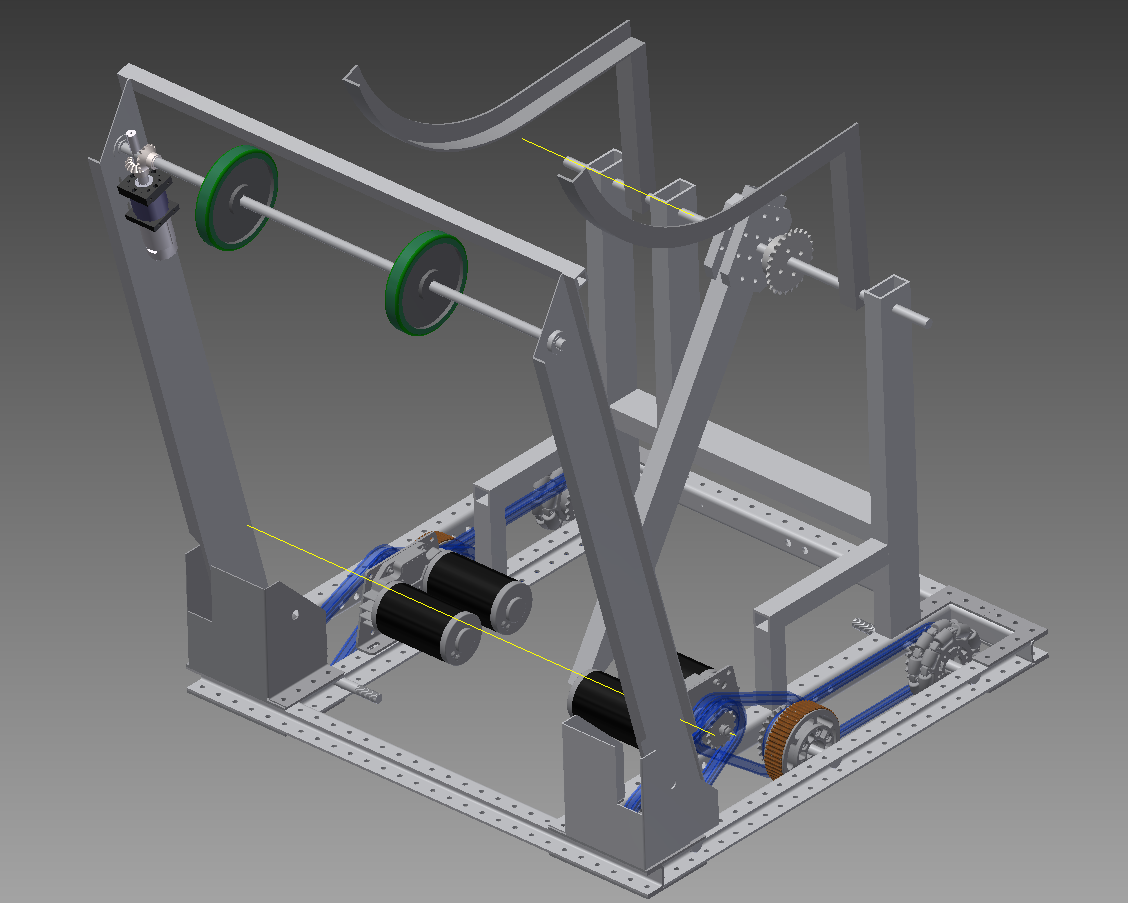

Current Design

- shooting takes 1-2 seconds

- a kicker strikes the ball through 2 bars (cradle)

- Linked with intake with a motor in the cradle structure pulling and pushing intake

Equipment Requirements/Size

- Weight

- 45 LBS

- CIM motors

- 4 mini CIM - 2 regular CIM

- Control

- PWM or CAN, but PWM may be preferred as it may be faster - cRio CAN is derived from RS-232 with max data speed of 115,200 bps.

Thurs Jan 9

Sat Jan 11

- Still working on Fundamentals for design

- Calculating how far the kicker has to move

- Calculating if motor driven is possible for Kicker

- met with collection

- integrate our cradle with the collection

- What type of material should we use

- Better to have a longer kicker than a lighter one

Accomplishments/Results

- Kicker must move about 80 - 90 degrees

- If you go any less than that you need more motors

- How to stop kicker motion

- nylon strap

- blocking plate

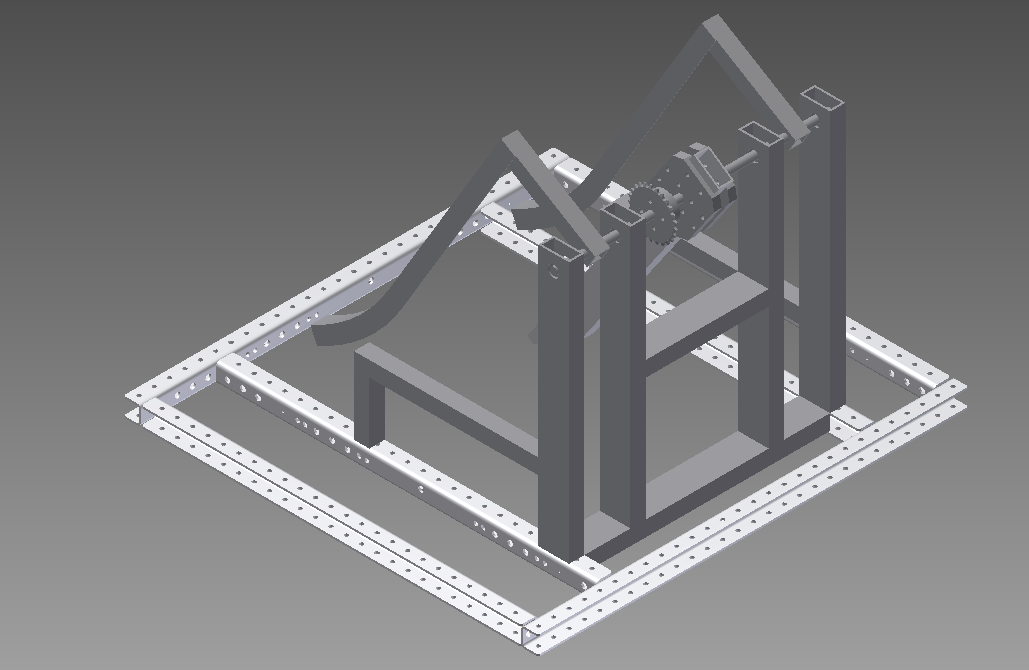

End of Day Design

Sun Jan 12

- Continue work on 3D design in inventor

- Determine geometry of Our kicker to the ball and cradle

- Our kicker has to be curved at some point so that we get the max speed into the ball rather than rotation

- We Finished drive trains CAD

- Worked on CAD for shooter

Tues Jan 14

- worked more with intake to get a linkage working

- messed some more with the geometry of the shooter

- Made a physical mock-up of the shooter

*cradle

- kicker

- Worked more on the CAD mock-up