2016:Lifter: Difference between revisions

No edit summary |

Programming (talk | contribs) No edit summary |

||

| Line 3: | Line 3: | ||

We have come to the conclusion that the best method of scaling the castle near the end of the match is using a telescoping arm to latch onto the bar and then lift with the arm. | We have come to the conclusion that the best method of scaling the castle near the end of the match is using a telescoping arm to latch onto the bar and then lift with the arm. | ||

= 2. | = 2. Motors and Sensors = | ||

<span style="font-size:larger;">Scaler arm extend:</span> | |||

<span style="font-size:larger"> | <span style="font-size:larger">Two 775pro motors</span> | ||

<span style="font-size:larger"> | <span style="font-size:larger"></span><span style="font-size:larger;">12T versaplanetary 100:1 with Vex Adapter </span><span style="font-size:larger"></span> | ||

<span style="font-size:larger"> | <span style="font-size:larger;">One Retroreflective sensor (EE-SPY415) to determine when the scaler is at its high end stop.</span> | ||

<span style="font-size:larger;">One Optical Flag sensor (OPB815WZ) to determine when the scaler is at its low end stop and home for encoder. </span> | |||

<span style="font-family:arial,helvetica,sans-serif;"><span style="font-size:larger;">One Shaft Encoder (GrayHill <span style="line-height: 15px;">61KS256) for use to measure scaler extension location. </span></span></span> | |||

<span style="font-size:larger;"></span> | |||

<span style="font-size: medium; line-height: 28.7999992370605px;">Scaler Pivot Arm:</span> | |||

<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium">Use Versaplanetary 100:1</span></span></span></span></font> | <font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium">Use Versaplanetary 100:1</span></span></span></span></font> | ||

| Line 30: | Line 28: | ||

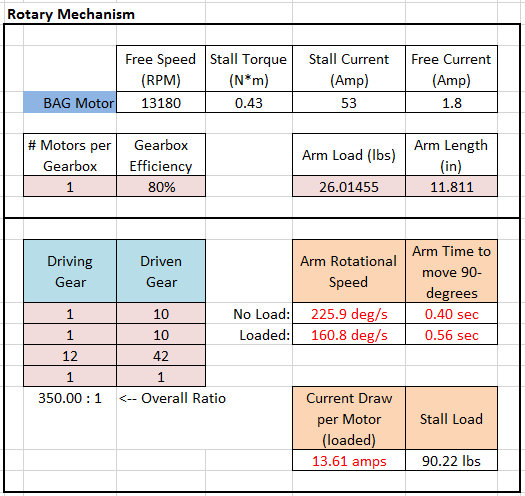

<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium">[[File:Scaler Pivot Arm Calc.PNG|RTENOTITLE]]</span></span></span></span></font> | <font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium">[[File:Scaler Pivot Arm Calc.PNG|RTENOTITLE]]</span></span></span></span></font> | ||

<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium">Two </span></span></span></span></font><span style="font-size: 15.6000003814697px; line-height: 24.9600009918213px;">Optical Flag sensor (OPB815WZ) to determine when the arm is at an end stop.</span> | |||

<span style="font-size: 15.6000003814697px; line-height: 24.9600009918213px;"></span><span style="font-family: arial, helvetica, sans-serif; font-size: 15.6000003814697px; line-height: 24.9600009918213px;">One Shaft Encoder (GrayHill </span><span style="font-family: arial, helvetica, sans-serif; font-size: 15.6000003814697px; line-height: 15px;">61KS256) for use to measure the pivot arm location. </span> | |||

= <span style="font-size:x-large;">3. Update 1/26/16</span> = | = <span style="font-size:x-large;">3. Update 1/26/16</span> = | ||

Revision as of 16:25, 30 January 2016

1. The Plan

We have come to the conclusion that the best method of scaling the castle near the end of the match is using a telescoping arm to latch onto the bar and then lift with the arm.

2. Motors and Sensors

Scaler arm extend:

Two 775pro motors

12T versaplanetary 100:1 with Vex Adapter

One Retroreflective sensor (EE-SPY415) to determine when the scaler is at its high end stop.

One Optical Flag sensor (OPB815WZ) to determine when the scaler is at its low end stop and home for encoder.

One Shaft Encoder (GrayHill 61KS256) for use to measure scaler extension location.

Scaler Pivot Arm:

Use Versaplanetary 100:1

12 tooth sprocket on motor shaft driving a 42 tooth sprocket

Two Optical Flag sensor (OPB815WZ) to determine when the arm is at an end stop.

One Shaft Encoder (GrayHill 61KS256) for use to measure the pivot arm location.

3. Update 1/26/16

3.1 What we're working on

- Design rollers/stops for the arm stages

- Design lightning holes

- Design motor mountings and figure out how to attach to the drivebase

- Send parts to chamtek

- Finish CAD work

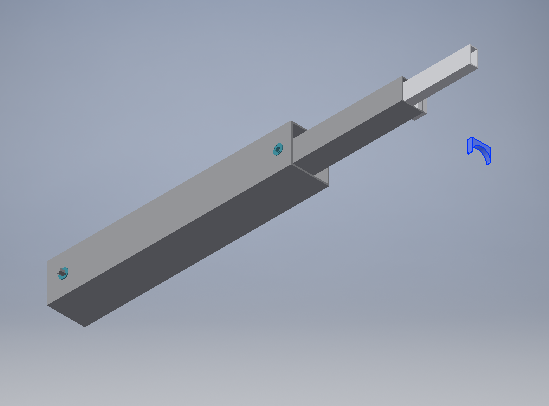

3.2 Photos

This is the hook we will be using.

This is the actual arm we designed.