2009:Robot Design Details: Difference between revisions

From 1511Wookiee

Jump to navigationJump to search

Leadership (talk | contribs) (motor updates) |

Leadership (talk | contribs) (Please update this section of the drivetrain) |

||

| Line 5: | Line 5: | ||

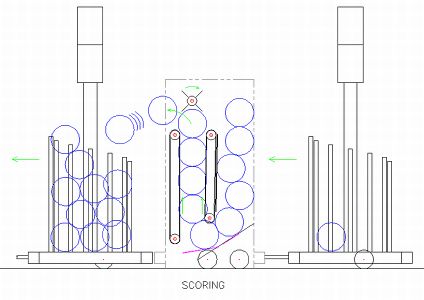

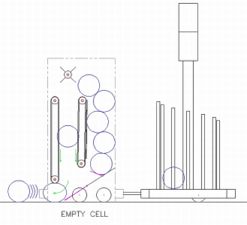

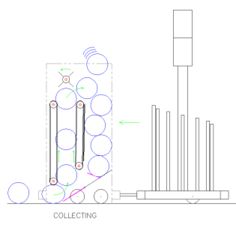

[[Image:Scoring 1.jpg|424x300px]] [[Image:Empty Cell 1.jpg|247x225px]] [[Image:Collecting_1.jpg|236x225px]]<br> | [[Image:Scoring 1.jpg|424x300px]] [[Image:Empty Cell 1.jpg|247x225px]] [[Image:Collecting_1.jpg|236x225px]]<br> | ||

== Drivetrain<br> == | == Drivetrain<br> == | ||

*4-wheel drive | *4-wheel drive | ||

| Line 11: | Line 11: | ||

*4 2.5" CIM motors | *4 2.5" CIM motors | ||

*Victor 884 [Drive] Speed Controllers | *Victor 884 [Drive] Speed Controllers | ||

*Fixed wheels (slip-style steering)<br> | *Fixed wheels (slip-style steering)<br> | ||

*Banebots encoders on each wheel (http://banebots.com/pc/ELECTRONICS/EN-G0561-KT) -- mounted at transmission outputs. | *Banebots encoders on each wheel (http://banebots.com/pc/ELECTRONICS/EN-G0561-KT) -- mounted at transmission outputs. | ||

*27.25” LONG x 37.25” WIDE<br> | *27.25” LONG x 37.25” WIDE<br> | ||

*Rear wheel axis at 5.625 from most rear surfaces (adjustable down to 4.625 corner brace regime permitting) <br> | *Rear wheel axis at 5.625 from most rear surfaces (adjustable down to 4.625 corner brace regime permitting) <br> | ||

*Front wheel axis at 11.625 from front most surfaces (adjustable ± 2.00”) | *Front wheel axis at 11.625 from front most surfaces (adjustable ± 2.00”) | ||

[[Image:Red_flag.gif|Please Update!]] | |||

*Still need to determine a few hardware items but I think we could use a few PEM fasteners to further minimize fastener system weight | *Still need to determine a few hardware items but I think we could use a few PEM fasteners to further minimize fastener system weight | ||

*We will need to design a few spacers “on the fly” as we determine the best approach while building | *We will need to design a few spacers “on the fly” as we determine the best approach while building | ||

| Line 23: | Line 26: | ||

*Need to design in provisions for front “dummy wheels” biased 1/8” up for roll over protection | *Need to design in provisions for front “dummy wheels” biased 1/8” up for roll over protection | ||

<br> | <br> | ||

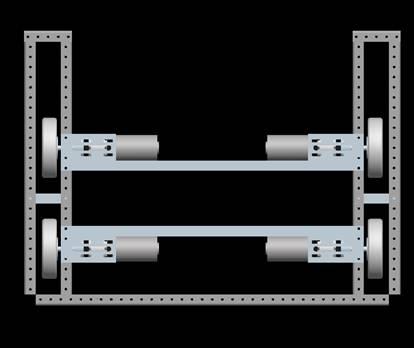

[[Image:Drivetrain 01-08-2009.jpg|Current Drivetrain design as of 01/08/2009]]<br> | [[Image:Drivetrain 01-08-2009.jpg|Current Drivetrain design as of 01/08/2009]]<br> | ||

<br> | <br> | ||

Revision as of 08:50, 14 January 2009

Main Robot Design

General layout design of the robot, Dimensions ARE NOT exact.

Drivetrain

- 4-wheel drive

- Banebots Transmissions

- 4 2.5" CIM motors

- Victor 884 [Drive] Speed Controllers

- Fixed wheels (slip-style steering)

- Banebots encoders on each wheel (http://banebots.com/pc/ELECTRONICS/EN-G0561-KT) -- mounted at transmission outputs.

- 27.25” LONG x 37.25” WIDE

- Rear wheel axis at 5.625 from most rear surfaces (adjustable down to 4.625 corner brace regime permitting)

- Front wheel axis at 11.625 from front most surfaces (adjustable ± 2.00”)

- Still need to determine a few hardware items but I think we could use a few PEM fasteners to further minimize fastener system weight

- We will need to design a few spacers “on the fly” as we determine the best approach while building

- The 6-hole patterns in the wheels need to be tapped for 10-32 Depth TBD

- Need to add the stiffener element between the wheels (1/side 1”x1” ext. Al stock is light and will work well and can be welded)

- Need to cut necessary smaller frame elements from stock

- Need to design in provisions for front “dummy wheels” biased 1/8” up for roll over protection

Lower Ball Collector

- Is now part of the front conveyor

Ball Hopper

- Open top entry for human player introduction

- Entry from conveyor at top of robot; entry controlled by upper ejector

- Exit is a "trap door" at the bottom of the hopper down to the area behind the lower ball collector and at the base of the conveyor system.

- Trap door and Lower collection blocker powered by Nippon Denso Window motor (possibly a rack & pinion arrangement?)

- Two Limit Switches sensors to tell when door is in open/closed position

- Jaguar speed controller

Ball Conveyor

- Two conveyors opposite each other, working together to move balls from ball intake and/or below the ball hopper up to the upper ball ejector/hopper entry point.

- Powered by two independent motors (RS-545 Banebots motors with 25:1 reduction gearboxes)

- Likely NOT direct drive, will likey be chain/sprocket to save space and move weight back on robot

- Banner Sensors: 42SMR-7100 Reciever and 42SML-7100 Source Mounted either at the top of conveyor load or bottom

- Jaguar speed controller

- Sensor to detect that conveyor is full

Upper Ball Ejector

- Spinning ejector directs, based on direction, balls out of robot or in to hopper entry point.

- Powered by Fischer Price 00968-2910 motor with plastic gearbox removed and TBD Transmission to be added

- Likely NOT direct drive, will be chain/sprocket to save space and move weight back on robot

- Jaguar speed controller