2016:Lifter: Difference between revisions

From 1511Wookiee

Jump to navigationJump to search

No edit summary |

No edit summary |

||

| Line 10: | Line 10: | ||

*<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large">Finish CAD work.</span></span></font> | *<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large">Finish CAD work.</span></span></font> | ||

*<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large">Select motors </span></span></font> | *<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large">Select motors </span></span></font> | ||

<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium"></span></span></span></span></font><span style="font-size:larger">Scaler Mechanism to Lift Robot:</span> | |||

<span style="font-size:larger">Two CIM motors</span> | |||

<span style="font-size:larger">AndyMark Toughbox Mini with 12.75:1 Ratio</span> | |||

<span style="font-size:larger">#35 Chain with a 12 tooth sprocket on the transmission shaft going to a 28 tooth sprocket on the scaler mechanism. This is contingent on the gearing inside the scaler mechanism.</span> | |||

<span style="font-size:larger"></span> | |||

<font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium">Scaler Pivot Arm:</span></span></span></span></font> | <font size="4"><span style="line-height: 28.7999992370605px"><span style="font-size:large"><span style="font-size:small"><span style="font-size:medium">Scaler Pivot Arm:</span></span></span></span></font> | ||

Revision as of 17:54, 26 January 2016

1. The Plan

We have come to the conclusion that the best method of scaling the castle near the end of the match is using a telescoping arm to latch onto the bar and then lift with the arm.

2. To Do

- Figure out the measurements that are alotted to the scaler team.

- Collaborate with the drivetrain team to ensure that those measurements will work well.

- Design the telescope nesting arm.

- Finish CAD work.

- Select motors

Scaler Mechanism to Lift Robot:

Two CIM motors

AndyMark Toughbox Mini with 12.75:1 Ratio

#35 Chain with a 12 tooth sprocket on the transmission shaft going to a 28 tooth sprocket on the scaler mechanism. This is contingent on the gearing inside the scaler mechanism.

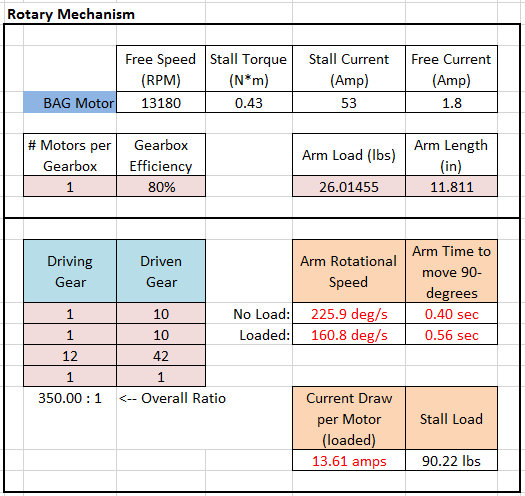

Scaler Pivot Arm:

Use Versaplanetary 100:1

12 tooth sprocket on motor shaft driving a 42 tooth sprocket

3. Update 1/26/16

3.1 What we're working on

- Design rollers/stops for the arm stages

- Design lightning holes

- Design motor mountings and figure out how to attach to the drivebase

- Send parts to chamtek

- Finish CAD work

3.2 Photos

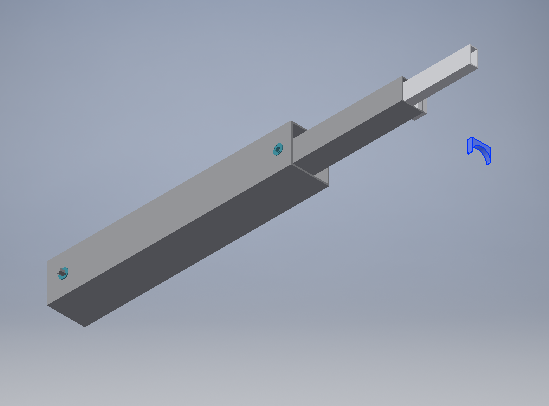

This is the hook we will be using.

This is the actual arm we designed.