2013:Climber Subteam

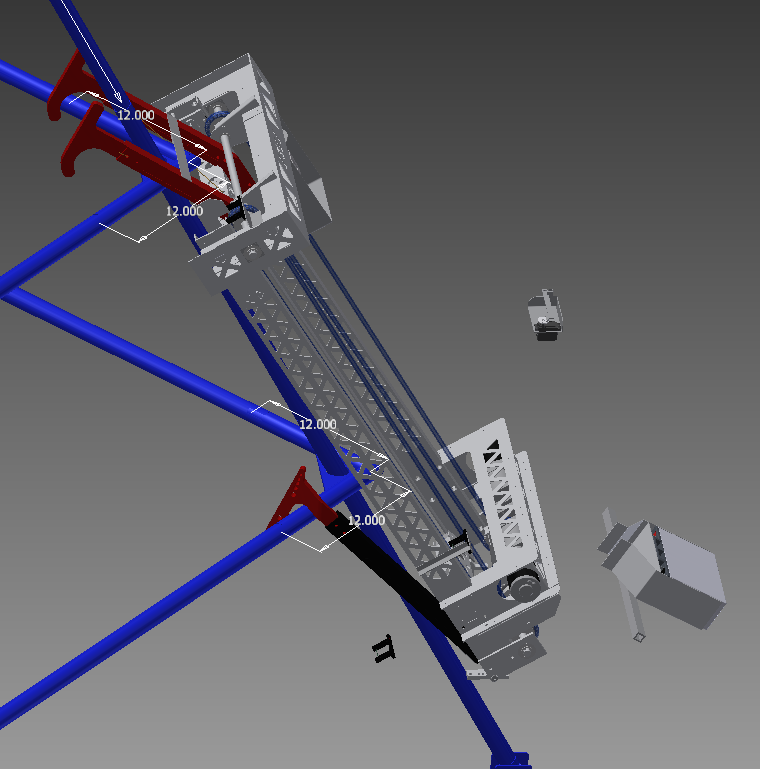

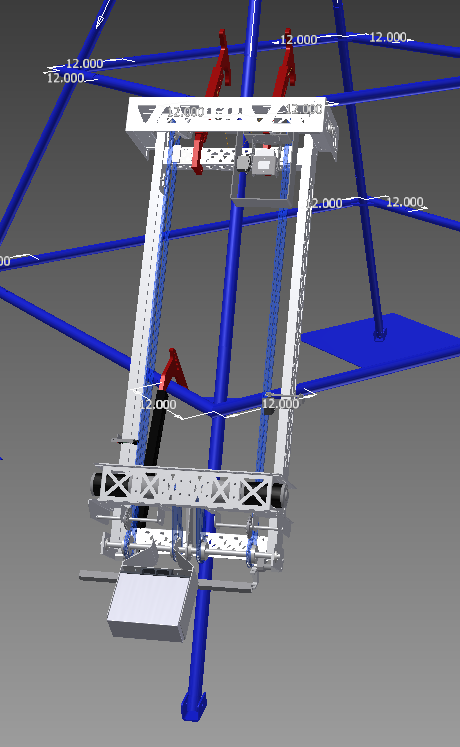

Climber Design

For aligning the pyramid, the "V" sensor is not enough. The robot may still be too far to the right or left. If too far right/left, then only one side of the arms would grab the bars. Sensors on the lifting arms, at the height of the level 1 horizontal bars, will be used. In order to climb, the "V" sensor and both arms sensors will need to be tripped; this will give 3 points of contact and 'guarntee' alignment for climbing.

Both sets of arms will be below the level 1 horizontal bar at the start of the match. So the lefting arms will need to raised prior to deploying the arms. If that is not done, and the robot is not perfectly align, one arm might end up inside the pyramid and get catch on the bar as the arms are raised. An additional flag sensor will be added to the arm track so when it is tripped, the arms will be at the proper height. The proper height is such that that sensors of the lifting arm will be at the height of the level 1 horizontal bar.

Deploying will involve moving the lifting arms to the alignment flag position, then the servos will be moved to release the arms.

The drivers will be responsible for engaging the "V" sensor and deploying the arms; this can be done in either order. The aux driver will then press and hold a button to climb. The robot will preform the entire climb. This means, the robot will automatically turn to get both arm sensors tripped (i.e. auto align the robot to the pyramid), then move the lifting arms up, then pull the robot to level 1, then move lifting arms to next level, then pull robot to level 2, and so on until at level 3. If the driver wants to abort the climb, they just release the button. This allows the driver stop the climb at any level and abort if they see something wrong. The button can be re-pressed and the robot will continue the climb, if possible. NOTE: during climb, the primary joysticks will not move the wheels

So we do not violate the 54" rule, the shooter will need to be in the home position before climbing. This means the "Deploy" for the arms will not work unless the shooter is at the required angle. Shooter will move to required angle by manually moving slider or by pressing the button that makes the climber the front of the robot.

Sensors:

| Area | Type | Description | Operation | Notes |

| Fixed Arms | (2) Beam Break Sensor - Photo transistor (Vishay TEST2600) IR LED (Vishay TSAL6100) | Detects when the arms are in position for the robot to hang and is being hung. | The sensors are tripped when the arm has 'snapped' against the horizontal bar after just riding up and over it; meaning the robot can now be lowered onto the bars and be hung. The sensor will remain tripped while the robot is hung (TBD). |

CHANGE !!! Each side will be fed back to the cRIO, (not AND'ed together as previously). Logic HIGH = sensor blocked. |

| Moving Arms | (2) Beam Break Sensor - Photo transistor (Vishay TEST2600) IR LED (Vishay TSAL6100) | Detects when the arms are in position for the robot to be pulled up. | The sensors are tripped when the arm has 'snapped' against the horizontal bar after just riding up and over it; meaning the arms can be lowered and the robot pulled up to the next level. |

Each side will be fed back to the cRIO. Logic HIGH = sensor blocked |

| "V" | Banner Pair (Q10RN6R and Q106E) | Detects when pryamid leg is in the "V" | Is tripped when the leg is far enough into the "V" that climbing can begin. And stays engaged when the leg is all the way into the "V". | Logic LOW = sensor blocked |

| Arm Track Top | Slotted Optical (OPB819) | Detects when lifting arms are at the top of the track | This is at the limit of travel. Software will kill the motor power if this is tripped. | Logic LOW = sensor blocked by flag |

| Arm Track Bottom | Slotted Optical (OPB819) | Detects when lifting arms are at the bottom of the track | This is at the limit of travel. Software will kill the motor power if this is tripped. | Logic LOW = sensor blocked by flag |

| Arm Motor Shaft | 10-turn potentiometer (3590S-2-103L-ND) | Detects arm motors moving | Used to control the speed of the motors. The torque will be different: 1) no load just moving arms up and lowering the first inch or so to latch on the bar; 2) when lifting the robot up the leg; 3) lifting the robot over the knuckle. | Shaft rotates ~7 full revolutions |

| Arm Track Deploy | Slotted Optical (OPB819) | Detecs when lifting arms are in the proper position to align to tower. | When the robot tower is in the depolyed position, the arms will travel to where the flag is positioned. This position is chosen such that the "Moving Arms" sensors are in a position that will allow the moving-arm sensors align the robot (i.e. at the height of the level 1 horizontal bars. | Logic LOW = sensor blocked by flag |

Motors/Servors/Actuators:

| Type | Description | Operation | Notes |

| CIM (2) | Moves the lifting arms | If not in lift broken mode, the encoder and a PID are used to control the moving of the arms. If in lift broken mode, buttons on the joystick will be used to drive the motor at a constant speed. | 40A circuit |

| Servos (2) | Deploys the arms | Releases pins that are holding both arms, so the arms are extended and can be used for climbing. |

Lights (on robot):

| Area | Type | Description | Operation | Notes |

| "V" engaged | Will be 'green' when pryamid leg is in the "V". Will be 'red' when not in contact. Flash when Level 1 (and higher) is achieved. | Light only has meaning when climber side is the 'front' or arms have been deployed. Re-use "have 1 disc" light. | ||

| Lifting arms engaged | Will be 'green' when both moving/lift arm sensors are engaged on a bar. Will be 'red' when arms sensors are not engaged. Flash when Level 2 (and higher) is achieved. | Light only has meaning when climber side is the 'front' or arms have been deployed. Re-use "have 2 discs" light. | ||

| Arms aligned | Will be 'green' when both Fixed Arm Alignment sensors are tripped. Will be 'red' when arms sensors are not tripped. Flash when Level 3 is achieved. | Light only has meaning when climber side is the 'front' or arms have been deployed. Re-use "have 3 discs" light. | ||

| Level Indicator | "Have 1 disc" light will flash when level 1 and higher is achieved; "Have 2 disc" light will flash when level 2 and higher is achieved; "Have 3 disc" light will flash when level 3 is achieved. The color being flashed will depend on the state of the above lights. | |||

| Unable to deploy | Used to aid the aux driver because the shooter is not at the proper angle to allow deployment when the Deploy Button is pressed. Flash all "have disc" lights like a rave. |

Operator Controls:

| Area | Type | Description | Operation | Notes |

| Aux Driver | Button | Deploy | While pressed, and shooter at the required angle, the two servos will be move to release the pins that are holding the arms. | Aux driver must put the shooter slider at the required angle OR the climber must be the front of the robot. |

| Aux Driver | Button | Climb | While pressed, if auto-climb is not broken and "V" is engaged, the robot will auto-align with the pyramid and climb all 3 levels. Releasing the button will stop the climb. Re-pressing the button will resume the climb, if possible. | Button must be pressed and held. While being held, the Primary Driver joystick Y-axis will not move the wheels. |

| Aux Driver | Button | Arms up | While pressed, if auto-climb is broken, the arm motor would be turned at a constant speed to raise the arms | |

| Aux Driver | Button | Arms down | While pressed, if auto-climb is broken, the arm motor would be turned at a constant speed to lower the arms | |

| Broken Switch | Auto-climb Broken | When not broken, the robot will automatically align with the pyramid and perform the climb. When broken, the primary driver will need to align the arms with horizontal bars and the aux driver will use buttons to move the lifting arms. | Set broken if any of the 6 arm sensors OR the "V" sensor are not working. | |

| Broken Switch | Arm Broken | When not broken, the encoder and a PID are used to control the lift motors. When broken the arms will move at a constant speed. | Set broken if the Arm Motor Encoder is not working. | |

| Broken Switch | Climbing Completely Broken | When not broken, entire mechanism works based on the above 2 broken switches. When broken, nothing will work. | Set broken if any motors/servors/actuators are not working. |

Resources

Climber's Engineering Notebook

Week 1

- Brainstormed different climbing ideas

- Created Rough 3D CAD prototype models of different climbing mechanisms

Week 2

Week 3

Week 4

Week 5

Week 6

Engineering Notebook Templates Available at:Engineering_Notebook_Template

Please Label All Notebook Pages 2013:Climber XX.XX to avoid confusion.