2024:Gamepiece

1/14/2024 - Prototyping Starts!

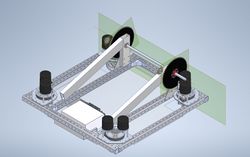

For our team's note acquisition/shooter mechanism, we took inspiration from the design of the Unqualified Quokkas Ri3D team. We worked in CAD on our version of this design, keeping some elements similar while making some modifications of our own. We also figured out some 2D geometries/measurements relating to robot interaction with source and trap. Also, we worked on assembling prototype of mechanism (base assembly of the prototype is mainly completed with the exception of belts and chains.

1/16/2024 - CAD and Prototyping is now in full swing!

Today, we tested out a diffuse reflection sensor for sensing game pieces, continued evaluation geometries for scoring positions in CAD (specifically those relating to placement of game pieces in the amp and trap and acquisition from source) and analyzed potential scoring angles, and started CAD design for worm drive brake actuation. We also continued assembly of our prototype mechanism (added belts and motors to prototype).

1/17/2024 - Revision of Prototype design

To make our prototype design grippier, we replaced all red compliance wheel axles on prototype with both red and green compliance wheels to make them grippier. We also worked on a CAD design for a new mechanism attachment intended to score notes into the trap. This mechanism consists of a claw that is intended to hold the note and place it directly into the trap. We coordinated with our Hang subteam to determine an distance above the ground that was possible for our current hang design and also ideal for the claw design we have.

1/18/2024 - CAD Design continues for our arm

We continued work on our physical prototype of our intake/shooter mechanism (mechanical assembly is mainly complete, we are adding belts, motors, and wiring). Also, we did more work in CAD on ideas to attach our intake/shooter assembly to our drivebase, our current idea is an arm, we currently have created the superstructure for this assembly in CAD. It currently consists of two angle braces and two vertical braces, the vertical braces are mounted to our drivebase with mounting plates and is where the pivot point for our arm is located, and the angle braces offer additional support for the superstructure.

1/20/2024 - Testing the Prototype!

We tested our prototype intake/shooter mechanism by intaking a note, outtaking it, and shooting it. It was successful! We are considering changing the gearbox on the transmission for the motor that drives our intake and outtake to get more power for intaking and outtaking notes. We also continued design of our arm to attach our arm to our robot. A design is in the works, and we are working on finalizing it so we can prototype the arm for more accurate testing of our intake/shooter mechanism in relation to the robot. We also worked on a design for a worm gear brake for our arm and worked further on placement of our designs within the CAD for our robot. We built a mockup of the arm and put it on the Kitbot drivebase. We also attached the intake/shooter to it.

1/21/2024 - It's All Coming Together In CAD!

Today we continued testing of our prototype intake/shooter mechanism with different angles and speeds and their success in relation to making it into the speaker, testing the prototype mounted onto a frame for reference. Once we finish our design for our arm, we can continue prototyping to gain more accurate representations of how our mechanism will act with us using our revised version of the arm. In CAD, we've started to put our intake/shooter assembly and arm assembly into one assembly connecting the two. We iterated on the lengths of our arm to find a length that would keep us within the 12in. maximum extension from frame perimeter limit, while also allowing us to still be able to score into the amp.

1/23/2024 - Our Arm Gets Re-Revised

After discussing with our other build season subteams, we decided there was a need to modify our arm for increased accessibility for maintenance. The base design of our arm is mainly finalized, as our full mechanism including the arm and intake/shooter mechanism includes 5 motors as of today: 2 NEOs to drive our shooter, one NEO 550 for our intake, one NEO for our arm movement, and a NEO 550 for our arm brake. Our subteam is working to finalize the sensors we need to use for our mechanism, and we are currently using a reflection sensor for detecting when a note enters our intake and an absolute encoder for the arm position. We also worked on finalizing our mechanism CAD so we can put it into a final robot CAD and prepare for the start of fabricating parts.

1/24/2024 - Introducing Our Brake Mechanism

We worked on designs to control our arm movement, deciding on a brake mechanism that is driven by a worm gear box and involves bicycle brake calipers to stop the rotation of a brake disc on the axle that pivots our arm, stopping our arm movement. We are coordinating with our team's hang and electrical subteams to determine the best location for this worm gear box. Our subteam also discussed ways to make the arm more accessible for maintenance, specifically access to motors and being able to easily replace belts, as our current mechanism requires the axles the pulleys are on to be taken out so we can remove the pulleys the faulty belt is on, which is unfavorable as it requires removing two axles from one side of our arm mounting, and as such is not as easy to accomplish as possible. We also had talked about modifying the location

of our transmission that drives our pivot axles so that they can be more easily accessed, and discussed potentially modifying the plates that mount our arm to our drivebase frame to give the arm more support.

1/25/2024 - Supporting "The Shamptake"

As we continue work on our acquisition and launching mechanism, which we have decided to call "The Shamptake", due to its multi-purpose design allowing it to shoot notes, score them in the amp, and intake/outtake them. We also created new mounting plates to strengthen the support of our arm superstructure that mounts our arm to our robot's drivebase, and modified the angled arm braces in our superstructure so they are smaller and have holes to mount the plates connecting the vertical braces to the angle braces.

1/27/2024 - On the Grind

Today was a busy day for us as we continued to work on our CAD for our mechanism, so we can finalize it and start fabricating parts. We edited some of the plates that mount our arm to our robot’s drivebase, finalized a representation of the brake mechanism we designed for our arm movement, and created new parts so we could mount the transmission that controls our arm’s movement to our vertical support braces. We also worked closely with our team’s hang subteam to ensure that any changes made would not affect their design, especially

as we moved into the more major design modifications during the day. Overall, we are nearly there with our CAD and our goal is to begin fabrication as soon as possible.

1/28/2024 - We're Almost There!

As we continue our mechanism CAD, we worked on adding some final touches to our CAD, assigning weights to our parts so we can gain a weight estimate of our overall mechanism, adding a hardstop to our arm, and adding lightening holes to our arm (pictured right). We also created new triangle brackets to mount our hardstop and to fit our modified arm cross beams, as we modified them to make them smaller and fit in-between our main arm tubes to decrease weight, and are pretty much done with our brake mechanism, as we worked on making some modifications and created a part so we could mount our brake. We also determined how much of certain materials we need based on measurements from our CAD, like certain lengths of different tubes we used in our arm assembly. We're almost done with the CAD for our Shamptake and our arm mechanism, and are preparing for fabrication of parts for our mechanisms!

1/30/2024 - More CAD!

Today we revised our brake mechanism to make sure that we could actually make it in our shop and we dove further into production of shop drawings for our mechanism's parts. We're not quite done with our mechanism CAD yet, but we're getting closer every day and only have a few minor modifications left until we can declare our CAD finished and shift to fabrication of parts. We are also making steady progress in producing and revising a prototype of our Shamptake.