2016:Controls

Overall concept

The two driver controls will be XBOX controls.

There will be 7 broken switches.

The top of the controls is in the shape of a heater shield. The entire top/shield is detached (no flip up sections); held on with magnets. This allows the shield to be held by the coach/spy during the match. The marketing team will provide the graphic for the shield.

The base will have a strap so driver can carry the entire controls on their back.

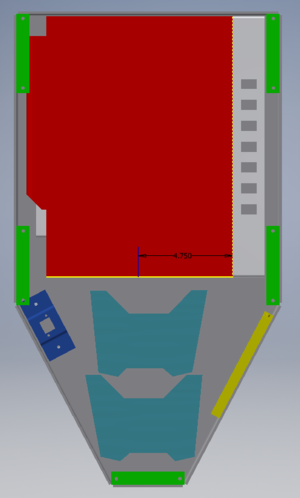

Green - Plates for magnets

Red - laptop

Silver - laptop bracket with holes for broken switches

Blue - XBOX controllers nested together

Dark Blue - Ethernet Bracket (currently interfering with the controllers, working on fixing)

Yellow - Lightning bolt USB hub

Todo

Other

- Look over painted parts to see if any touch up is needed

- Attach steel for magnets to shield (use nylon nuts [in plastic bag in blue controls container]; but re-test fit first to make sure steel in correct corners).

- Could have marketing paint shield (just tell them that tape might pull off the paint, so have them becareful)

- Attach guitar strap holders to base (bolts and nuts in plastic bag in blue controls container; see how we did it last year)

- Attach ethernet and laptop brackets to base (nylon nuts in plastic bag in blue controls container)

- Put velcro on laptop bracket (see laptop to make sure you put the proper side on it; look at previous years controls)

- Put blue spade connectors on ribbon cable for broken switches (strip 'double' the amount, twist, then bend over, then put into connector; make sure connector is oriented in crimper correctly) [Zach knows how to do this]

- Create 'jumper' wire to go from broken switch to broken switch (one side of all borken switches connect to negative on the eStop board).

- Temporarialy connect other end of ribbon cable to eStop board to valid the switches (plug into PC and look at buttons in Control Panel)

- Come up with ideas for dashboard layout and controls (look at minutes from our mtg with strategy on 1/30)

Make sure the Cypress board can emulate a HID(see 1/23/16 minutes).- lights board: which one; location; mounting; power

- Do we need a 5V supply for lights, if so which one.

- Update SW on the laptop, Jeff has the stuff on a thumb drive and offered to do it if we aren't doing anything special.

- Add more lights, make them cool.

- Map out I/O

Later Fabrication

- Create straps for the shield.

Dashboard:

Possible Features:

- Camera feed if we have cameras

- Position of breacher arm

Meeting Minutes

Update 1/19/2016

Present: Eric, Andrew, Ethan, Zach, Ryan, Jeff

Completed:

- Created a model of the laptop power brick

- Created a model for the Cypress board

- Eric did a little research on the Cypress board. It turns out you can use the debugger half as it's own board and write your own applications for it. It has a USB interface and the debugger implements a HID so we should be able to use it for a HID, probably needs a little more research and evaluation.

- Picked the shield strap, we will reuse last years because it is awesome.

- Put new strap "knobs" on the shopping list.

- Determined that we will do nylon straps on the shield. Will custom fabricate them at a later date.

- Created holes in the shield for these straps, locations are correct but we need PEMs instead of holes because they will look better.

- Picked the approach for attaching the shield to the box. We will use cabinet magnets on each of the corners of the box and corrosponding metal plates mounted on the shield.

- Finished and submitted the drawing for the laptop holder.

- Started a drawing for the shield, see the Todo list for what needs to be finished.

- Picked the retractable cord and put it on the shopping list. We will just retract it from inside the box. We picked the one we did because it was the longest. We may still need to hack on an end if we need multiple outlets and to add length.

- Created part numbers for the three parts (laptop holder, shield, base) on the parts fabrication spreadsheet.

Update 1/20/2016

Present: Andrew, Ethan, Zach, Ryan, Mr. Byers

Completed:

- Picked cabinet magnets

- Decided on PEM stud:

- FH-832-5ZI

- Thread Size: .164-32 (#8-32)

- Hole Size: .163 '± .003''

- Updated top of shield and PEM holes

- Decided ethernet mount and started creation of bracket in CAD

Update 1/21/2016

Present: Andrew, Ryan, Jeff, Mr. Byers, Eric

Completed:

- Correct (hopefully) drawing of the laptop base submitted.

- Continued work on the Ethernet bracket.

- Created model of the magnetic door latch.

- Added magnetic door latch model to the controls assembly.

- Created and placed brackets in the assembly to mate with the magnetic door latch.

Update 1/23/2016

Present: Andrew, Ryan, Eric, Zach, Ethan, Jeff, Mr. Byers

Completed:

- Decided on PEM stud:

- Hole Size: .163 ± .003\

- Thread Size: .164-32 (#8-32)

- FH-832-5ZI

- Finalize the placement of the magenetic bracket and steel plates.

- Add PEM studs for the steel plates in each corner of the shield to match up with the drawer magnets that are in the base

- This involves creating the steel plates which Eric thinks we should fabricate to be a bit thicker than the normal plates to give some extra holding power and alignment and have two screw holes.

- Finished drawings of laptop holder, shield, ethernet brachet and submitted them to Amy

- Looked at boards for lights/HID:

- PSoC 4 - could not find any HID samples; found them for PSoC3 & 5

- XMC1200/1300 - could not find any HID samples; they have some for XMC4400/XMC4500

Update 1/24/16

Present: Andrew, Zach, Ethan, Jeff, Mr. Byers

Completed:

- Added holes into base for magnetic cabinet latches

- Confirmed position of e-net bracket

- Created electronic assembly (and parts) to hold: joystick board, PSoC, power converter, lights electronics

- Add #8 screw holes on the corners of the base for the guitar strap knobs

- USB hub: location; mounting (use velcro)

- Positioned power brick and XBOX controls

- Fixed bend radius and size for base

- added handle (no holes yet, can adjust later)

Update 1/26/16

Present: Andrew, Eric, Mr. Byers

Completed:

- Completed base drawings.

Update 1/27/16

Present: Andrew, Ethan, Zach, Eric, Mr. Byers

Completed:

- Fixed base drawings and sent them off

- Received Laptop Holder, Shield and Ethernet Bracket

- Chose paint scheme

- Worked on LED controller

Update 1/28/16

Present: Andrew, Ethan, Zach, Ryan, Mr. Byers

Completed:

- Began to crimp wires for eStop Robotics CCI

- Helped make shop drawings

Update 1/30/16

Present: Andrew, Ethan, Zach, Ryan, Mr. Byers, Eric

Completed:

- adjusted steel for magnets/gt shield to fit

- cleaned up welds on base

- met with strategy to go over control button mappings and items desired for the dashboard

- determined USB cable extensions not needed for controllers

- Spray painted parts

Update 1/30/16

Present: Jeff, Ethan, Ryan

Completed:

- Attached ethernet cable to bracket

- Moved painted stuff to our closet space.

- Ethan helped work on the drivebase

Update 2/2/16

Present: Jeff, Andrew

Completed:

- Attached velcro to top of laptop tray