2009:Robot Design Details

From 1511Wookiee

Jump to navigationJump to search

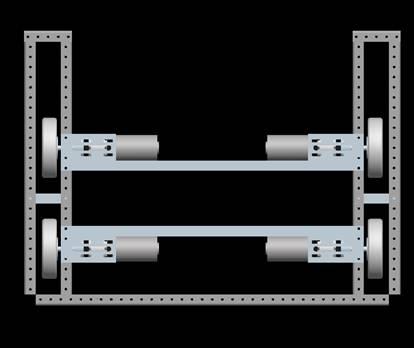

Drivetrain

- 4-wheel drive

- Banebots Transmissions

- 4 2.5" CIM motors

- Victor 884 [Drive] Speed Controllers

- Fixed wheels (slip-style steering)

- Banebots encoders on each wheel (http://banebots.com/pc/ELECTRONICS/EN-G0561-KT) -- mounted at transmission outputs.

- 27.25” LONG x 37.25” WIDE

- Rear wheel axis at 5.625 from most rear surfaces (adjustable down to 4.625 corner brace regime permitting)

- Front wheel axis at 11.625 from front most surfaces (adjustable ± 2.00”)

- Still need to determine a few hardware items but I think we could use a few PEM fasteners to further minimize fastener system weight

- We will need to design a few spacers “on the fly” as we determine the best approach while building

- The 6-hole patterns in the wheels need to be tapped for 10-32 Depth TBD

- Need to add the stiffener element between the wheels (1/side 1”x1” ext. Al stock is light and will work well and can be welded)

- Need to cut necessary smaller frame elements from stock

- Need to design in provisions for front “dummy wheels” biased 1/8” up for roll over protection

- Need to order the following parts from the shop by tomorrow (01/09/2009):

- 2009-wheel-hub (1/8 wheel retainer plate) QTY:4

- Hub-bearing (just a spacer in the hub for support not a bearing) QTY:4

- Brkt-wheel-asy-1 (trans/motor mount left front and right rear) QTY:2

- Brkt-wheel-asy-2 (trans/motor mount left rear and right front) QTY:2

- Bearing-block (main double bearing holder for each drive assembly) QTY:4

Lower Ball Collector

- Is now part of the front conveyor

Ball Hopper

- Open top entry for human player introduction

- Entry from conveyor at top of robot; entry controlled by upper ejector

- Exit is a "trap door" at the bottom of the hopper down to the area behind the lower ball collector and at the base of the conveyor system.

- Trap door powered by XXX motor (possibly a rack & pinion arrangement?)

- Two Limit Switches sensors to tell when door is in open/closed position

- Jaguar speed controller

Ball Conveyor

- Two conveyors opposite each other, working together to move balls from ball intake and/or below the ball hopper up to the upper ball ejector/hopper entry point.

- Powered by two independent motors (XXX motors)

- XXX sensor to detect ball "ready to shoot" at the top of the conveyor.

- Jaguar speed controller

- Sensor to detect that conveyor is full

Upper Ball Ejector

- Spinning ejector directs, based on direction, balls out of robot or in to hopper entry point.

- XXX motor powered

- Jaguar speed controller