2019:Cargo Mechanism

From 1511Wookiee

Jump to navigationJump to search

1/27/2019

Work done:

- Realized that beam break sensor would not work

- tested several different types of sensors

- determined that we either want a retroreflective sensor or microswitch

1/26/2019

Work done:

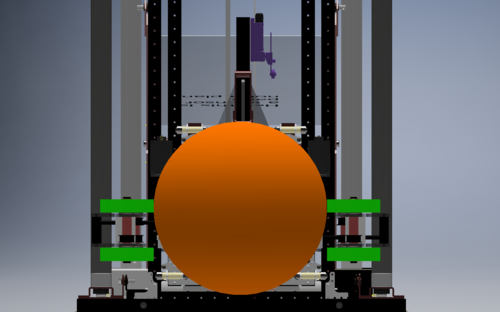

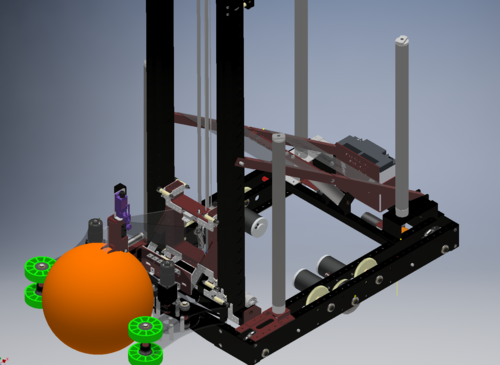

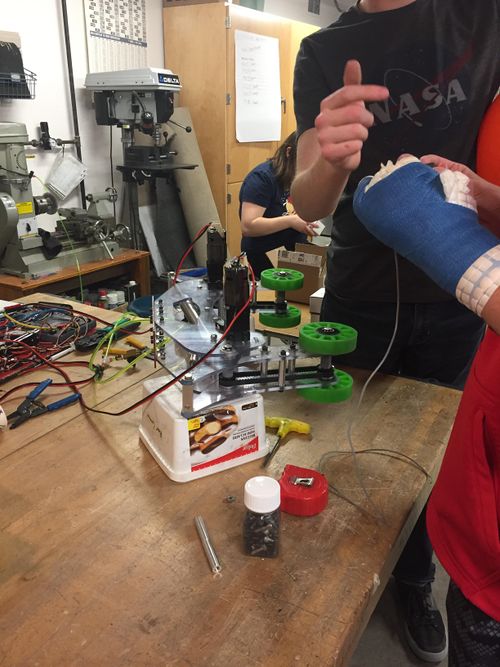

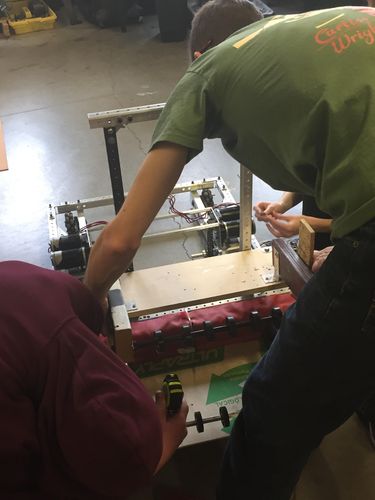

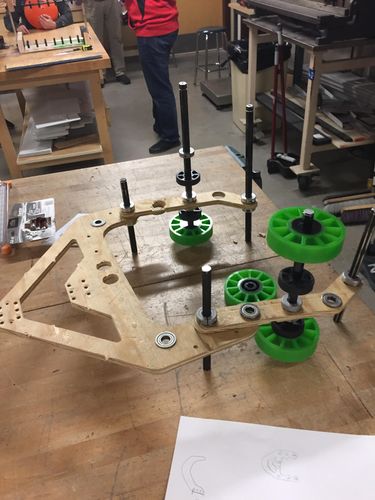

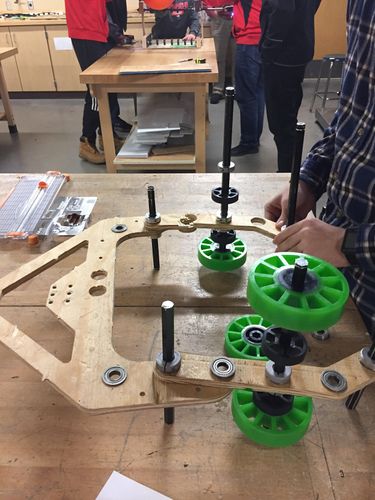

- Assembled and tested prototype of cargo assembly

1/19/2019

Goals

- Finish deisgn in CAD.

- Create shop drawings

- Finish shopping list

Accomplishments/creations

1/17/2019

1/16/2019

Goals

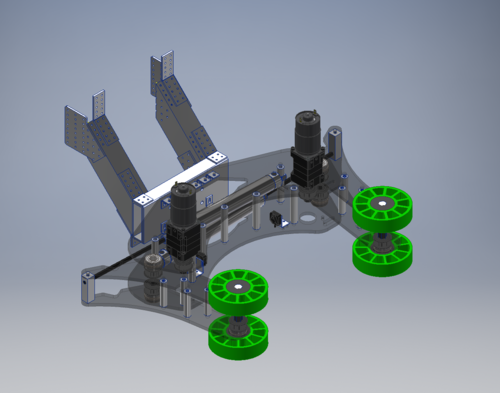

- Put in CAD

Accomplishments/creations

- Built in CAD

- In final robot design

1/15/2019

Goals

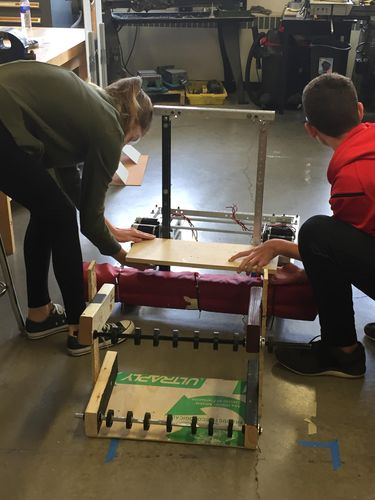

- Test different heights and offsets for cargo delivery

Accomplishments/creations

- Tested with different prototype

Learned

- We have a large margin where the cargo will go in rocket, Can be off 12" side to side, 6" up and down

1/13/2019

Goals

- Start design of cargo mechanism

Accomplishemnts/creations

- Big chunk of cargo

Concerns

- Fitting within bumper while arms are out

1/12/2019

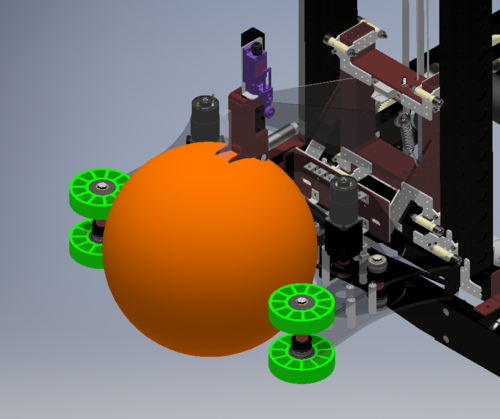

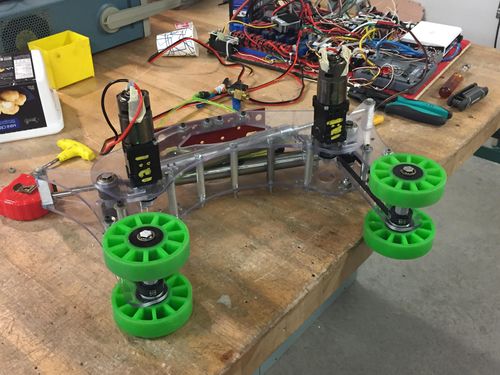

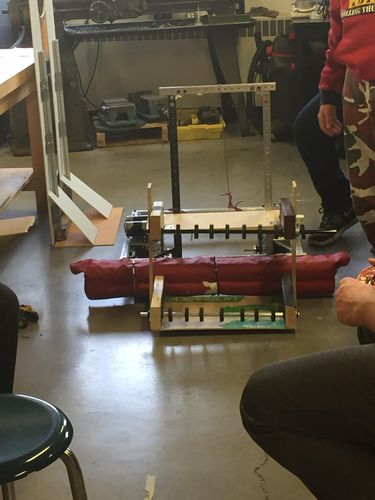

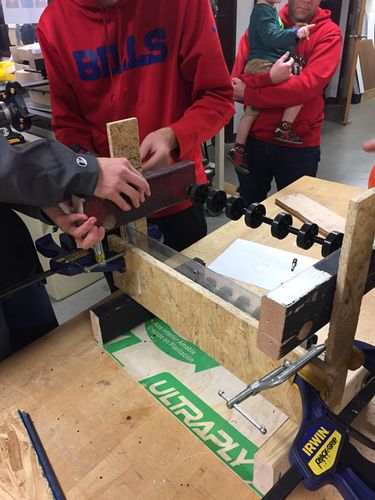

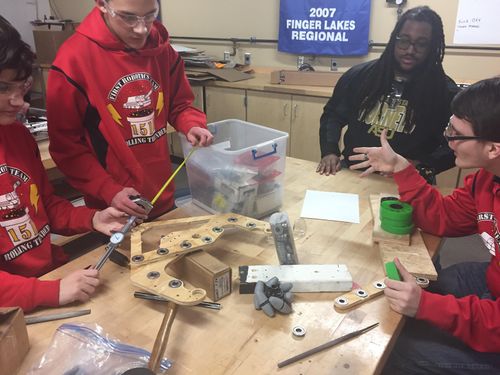

Prototyping Vertical Side Rollers

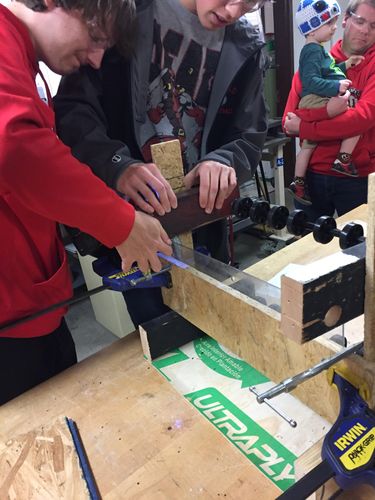

- Remaking because it broke at the end of the last meeting

- Measurements

- floor to bottom of wheels - 4 in

- floor to top of wheels - 8 in

- center of hex shaft axle to center of hex shaft axle - 15 5/8 in

- center of hex to backstop - 7 1/4 in

Prototyping Horizontal Side Rollers

- Attaching to the prototype robot

Cargo losing air

Cargo that was left out for 36 hours shrunk from 13" to 12.73" in diameter, which is roughly .0075" per hour and .18" per day. Cargo needs to be between 12.5" and 13.5". Expect more shrinking when the ball is used.

1/10/2019

Prototyping Vertical Side Rollers

- Fixing the Broken Arm

1/9/2019

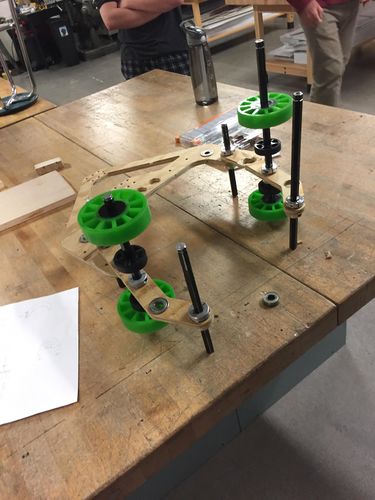

Prototyping Verticle Side Rollers *Assembly *Adding the wheels *

Prototyping Verticle Side Rollers *Assembly *Adding the wheels *

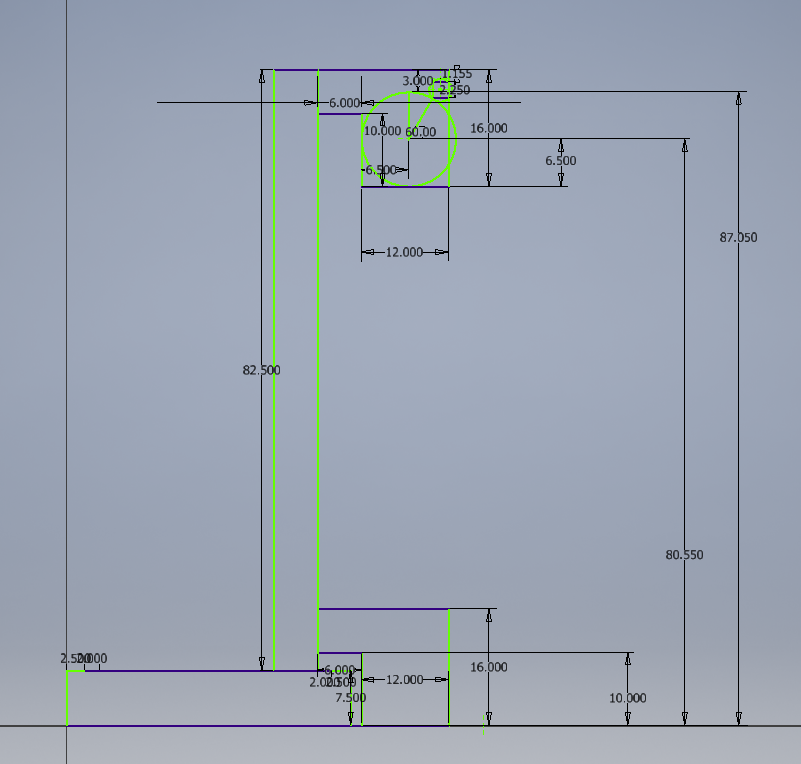

== 1/8/2019 == CAD sketch of Bucket design for cargo storage, dimensions to scale 1/8/2019.

== 1/8/2019 == CAD sketch of Bucket design for cargo storage, dimensions to scale 1/8/2019.