2020:Hang

Team Leads

Alex F. & Nicole L.

Pros and Cons

Pros and Cons of Each Design Option

| Telescoping Frame Design | Telescoping Arm | ||

|---|---|---|---|

| Pros | Cons | Pros | Cons |

| More Stable | Heavier | Lighter | Difficult to maintain |

| Fits within the allotted space better | Wider | Thinner | Having 2 hooks is harder * |

| Easier to maintain | Harder to add self balancing mechanism | Easier to add self balancing mechanism | Less stability |

| Easier to have 2 hooks | Single motor | ||

| Single motor | |||

Explanation

- Pros of telescoping frame

- More stable

- Due to having 2 arms that are connected, it is going to be more stable than a single arm.

- Fits within allotted space better

- We have a lot of space side to side, but front to back we only have 1-7 inches max. Since each stage can be the same thickn ess as the other ones (since they don't have to fit inside each other), the first stages can be thinner than the ones of the telescoping arm.

- Easier to maintain

- Since the stages are next to each other, instead of inside each other, it will be much easier to fix between matches.

- Easier to have 2 hooks

- Since the frame will already have 2 sides, it will be very easy to put a hook on the top of each side of the third stage.

- Single motor

- Despite having two sides, the frame is still extended and retracted with a single winch in the middle of the two sides. Thereforem, it will only require a single motor (compared to a deplloyable hook which would likely require 2).

- More stable

- Cons of telescoping frame

- Heavier

- Since it has two sides, it will require more material than the telescoping arm, making it heavier.

- Wider

- The design has two sides, each of which will be three tubes of metal side by side. However, the telescoping arm will only require three total, which will be inside of each other.

- Harder to add self-orienting mechanism

- The self-orienting mechanism we protoyped really only works well with a single arm. It could be modified a bunch to work for two sides/a wider arm, or scaled up a bunch to work as it is.

- Heavier

- Pros of telescoping arm

- Lighter

- It's only a single arm, so it will require less material.

- Thinner

- The telescoping arm will only have 3 tubes of metal, with the last two being inside the first. Therefore, the mechanism will ony be as wide as the first stage (not including the winch).

- Easier to add self-orienting mechanism

- The self-orienting mechanism that we prototyped is designed to work with one arm, meaning that adding it to the end of the telescoping arm would not be too dificult (compared to the telescoping frame).

- Single motor

- This prototype also only requies a single motor, since it only has a single winch in the center.

- Lighter

- Cons of telescoping arm

- Less stable

- Since it would be a single arm anchored at a single point, it would be less stable and more prone to swinging around on the bar after climbing.

- Difficult to maintain

- Since the stages are inside each other, it would be much harder to repair between matches (see 2016).

- Harder to fit 2 hooks

- The center support in the middle of the bar is 3 inches wide. This makes a single telescoping arm with two hooks even less practical, as it requires the third (and thinnest) stage to be wide enough to fit 2 hooks with 3 inches in between. Stage 2 will then need to be even wider, and stage 1 will need to be even wider than stage 2. This means the telescoping arem would have to be very big to allow 2 hooks, adding more weight and potentially making it hharder to fit inside of the allotted 5 inches or so. This problem would be solved by putting the self orienting hook mechanism on the end though.

- Less stable

Prototyping 1/5/2020-1/11/2020

Overview: Based on initial team brainstorming and sketching, as well as the information from Strategy Subteam, we determined to prototype:

- Telescoping arm

- We are also prototyping a self-balancing mechanism.

- Deployed hook

- Hook designs

Observations: We observed the following over the course of prototyping:

- All prototypes work well.

- it juust works

Decisions:

- We will have two telescoping arms located on the DB frame at the center of gravity

- We will not attach parallel to the bar, we want to come at it perpendicular (drive into it)

- We have decided on the profile of the three stages (I guess not, now it's 2", 1.5", 1"?)

- We will have two hooks on a self-balancing mechanism.

- We have decided on the motor we are using (Neos)

Need to do:

- Need to finish fabricating parts (UMHW plates) (done)

- Need to start/finish assembling our telescoping arm and winch assemblies, and put them on the robot ASAP (like almost done, 80% there)

- Finish Hook design (will do this after on robot)

- Need to confirm we will have a second sensor to zero the encoder

- We need to figure out if we need another encoder besides the one on the Neo

- Need to figure out what springs we will use at the bottom mount (could use lexan or spring steel) (done)

- Need to put a safety hard stop for the arm so that it doesn't try to fling out when it's being stored (done, a bar probably across the hooks)

- Need to always be making sure we are below the shooter

- Need to always be making sure we are in the center of gravity

- Need to make sure that all non-COTS parts that will be modified have a part number

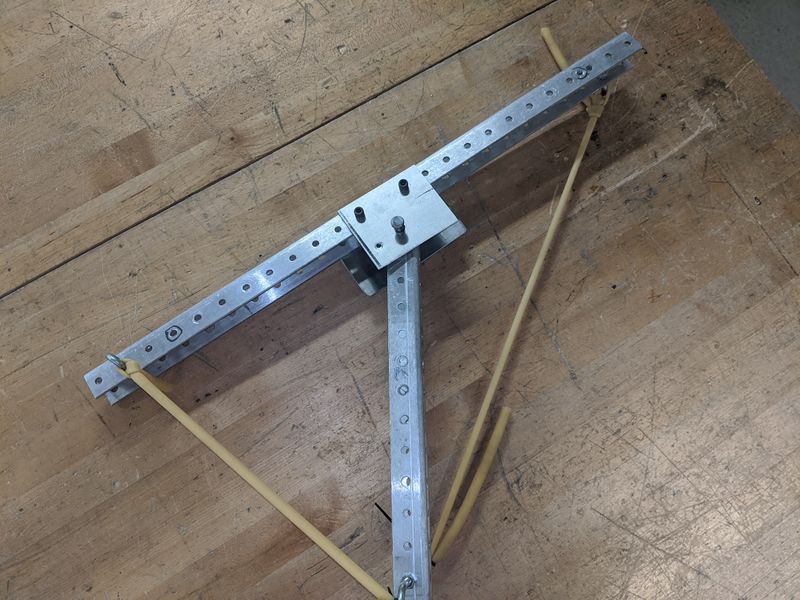

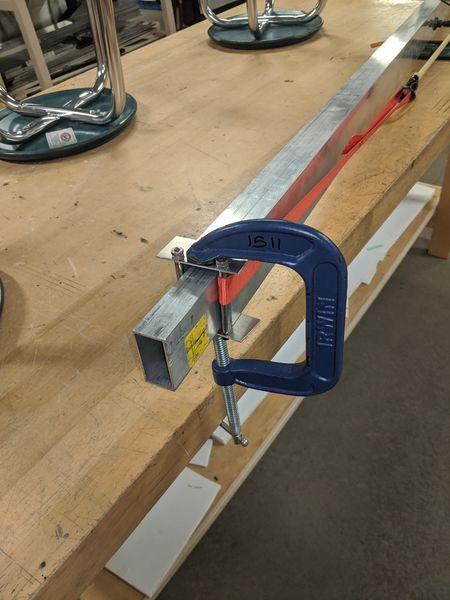

Telescoping arm Winch prototype

Telescoping arm Winch prototype

Telescoping arm prototype other end

Telescoping arm prototype other end

Design

1/11/2020- As a subteam (minus Ben), we decided on a design that has two telescoping arms on the center of gravity of the channel on the DB. The mechanism is made up of square/rectangular tubing with a constant force spring that is wound out when the arm is retracted and winds up back to a coil when the arm extends. The force the spring needs to lift is only the weight of the arm, which we estimate to be about 10 lbs per arm (currently it is around 2.5 lbs per arm, not including the crossbar, so we overshot). We will need a total of 8 constant force springs with 4 on each arm to allow the arm to extend and one motor to drive a winch which will keep the arm retracted during all the match except endgame, where the winch will drive the arm back up. We also decided that the only sensor we will need is an encoder on the motor, however we considered having a physical switch or a beam break in order to zero the encoder. We have also decided to use a single Neo 550, but since according to Jeff, the encoders on the Neos are unreliable and since the encoder will be the only sensor on the entire mechanism, we should probably add another one regardless. The strap will go through the middle of the two telescoping arms and above the wheels. It will then attach to a drum on an axle located as far back on the robot as possibe that connects the two drums together. The motor will then be in the center of the shaft and rotate the shaft using gears. We have also added a variety of different mechanisms to give the arm compliance and allow it to take hits from other robots and the bar, when we drive into it. We have added a way for the two hooks to pivot, so that when the bar is unbalanced and at an angle, both hooks witll still be able to grab it and the robot will not be held up at a weird angle. We still need to design a method of keep the two hooks at ~0 degrees when it is not being hung on. We also added a pivot to the entire hook and crossbar assembly to allow the hooks to start facing down. We will have a cross bar across the first stage of the arm that keeps the hooks in place, but when the arms extend, the hooks will move above the crossbar and flip out. They will flip up using torsion springs. Once the arms are extended, the hooks will still be able to pivot back and forth a bit, but will centered again with the torsion springs. We have a third pivot at the mounting plates of the arms that allow the entire assembly to pivot. This will allow another robot to slide into ours, with hopefully minimal damage (since the arms will hopefully not bend or snap, and instead just pivot a bit). This pivot will be centered with two tension springs, similar to the self-orienting prototype pictures above.

Strap: (https://www.strapworks.com/ProductDetails.asp?ProductCode=FNW12&gclid=CjwKCAiApOvwBRBUEiwAcZGdGC9bNVgTQgranl8ih_3NK1bXtC7pBgu-UmpWWLirkfr80HY2i77UZRoCh0AQAvD_BwE) 100 ft. Red

Constant Force Spring: https://www.mcmaster.com/9293k56

Shop drawings that are made, approved and printed:

Harris Parts

P101 | CF Spring Bracket

P188 | Hook Plate v2

P237 | Drum Mounting Plate

Shop Parts

P144 | Hang Bracket v2

P090 | Self balance horizontal arm

P124 | Inside Hanger Bracket

P125 | Outside Hanger Bracket P169 | Motor Mounting Bar

Daily Diary

1/7/2020

5:00-9:00 Attendance: Alex F, Nate S, Nicole L, Elliot W, Nevin W, Michael N, Ben S

We re-tested the telescoping arm and designed a self orienting hook mechanism base. Tommorow, we have to finish that and adjust the surgical tubing and add hooks to the bar. We need the tape measure spring for the final telescoping arm design if we choose to follow that route (and need the actual hooks, which are being prototyped as we speak/type). We have to decide if we want 1 or 2 telescoping arms still, it depends. See robot design for pictures or will update later. Videos are not allowed, on this wiki, so more pictures.

1/8/2020

5:00-9:00

Attendance: Nicole, Alex F, Nate S, Trevor W, Ben and Christian Stoeckl

Nicole/Stoeckl: I did the calculations for where both robots would have to hang and how heavy they are to be balanced, the file is on the harris drive as "Torque for Hang NL". This spreadsheet doesn't account for only one robot to hang and doesn't take the 8 deg of allowance from being balanced. Tommorow we will have to fix that so that it can display when a robot is balanced at the center which can help us figure out if we need one arm or two arms. Tommorow we also need to figure out the force to lift the robot with one or two robots which will lead us to know what type of motors we might need. We also still need to figure out the size of the constant force spring to bring up the hook alone. We have to CAD up a scale sketch of the different arms (telescoping arm and the deploying arm at least) with it on top of the drive base so we can see how many sections we will actually need to have.

Everyone that isn't Christian/Nicole: We finished the prototype for the self deploying hook by adding a quick hook to the end. We also fixed the tensioning on the self orienting hook prototype, so that the bar is relatively perpendicular to the arm. We then tested it by having it extend, put the hook over the bar, and then retract, leaving the hook on the bar. In theory, if we had another string attached to the hook, we would then be able to winch it. We discussed the pros and cons of having multiple hooks and/or having multiple arms. We decided against coming at the bar parallel. We still need to make decisions on basically everything.

1/9/2020

5:00-9:00

Attendance: Nicole L, Alex F, Nate S, Nevin W, Ben and Christian Stoeckl

Everyone that isn't Christian/Nicole: We narrowed down the options for our endgame mechanism between a telescoping frame and a telescoping arm. We also made sketches in Inventor modeling the two mechanisms to size. We established that having a two stage telescoping arm would require an arm that starts right at the 45" height limit. We made a pro/con list for each of them to present on Saturday. We will need to start working on 3D CAD designs for the mechanism we choose Saturday.

Christian/Nicole: We fixed the previous spreadsheet for hang to include the 8 deg balance allowance, this is on the Harris Drive as "Torque for Hang NL" in the 3rd tab i believe. The concept of this spreadsheet is similar to the last with some new variables given that there is now a change on how the 8 deg will effect where you can balance given that the robots are spaced apart a changable distance and weigh a changeable weight. I also did calculations on how many times a winch would need to rotate given a changable diameter and changable height the robot needs to be lifted. I then calculated how quickly some motors we commonly use (CIMs, 775 pros, etc) would take the weight of the robot up to climb. The quickest time was for 1.3 seconds going about 70 rotations/sec (i think i dont have access to the spreadsheet right now). We also figured out the gear box ratio. The reason we did this was so that we know how many motors we need to lift the robot, whether or not that is with one arm or two, the lift mechanism will only need one motor, which helps possibly eliminate the worry about using up our motor count depending on our hook config. I think that is all the calculations and Stoecklometry™ we needed to do to get a basic understanding of the requirements to lift and balance on the hanger, so now we just need to see how the robot design meeting goes.

nicole i deleted your stuff sorry :( (its ok i fixed it-NL :) )

1/10/2020

12:00-11:59

Attendance: Alex F, Nicole L

Alex F: Reformatted and added explanation for pro/con list.

Nicole L: Readded the entry that got mysteriously deleted by an unknown force

1/11/2020

10:00am-12:00am

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Elliot W (kinda), Herr Dr. Stoeckl

We began by redoing our design after 60% of the team had an issue with it. Under the lead of Herr Dr. Stoeckl we decided on a new design containing concepts from both the telescoping arm and the telescoping frame, featuring 2 telescoping arms located on the CG. We also decided that we would eventually use a ratchet and paul combined with servo to lock the telescoping arm in place. We also made a prototype with actual constant force springs to better simulate our design. We still need to lock Nicole in the cabinet, but this time make sure that she is actually being randsomed instead of just being kidnapped.

Stoecklometry™

1/12/2020

10:00am-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Dr. Stoeckl

We continued to work on CAD models for the Hang mechanism. We made a height calculator that could calculate the minimum and maximum height of the telescoping arms. We also began designing mounts for the telescoping arms, with rollers for the straps and an axle to rotate on. We also have continued work on hook designs, and completed the second iteration of the self orienting mechanism. The drum mechanism is still being worked on, and needs to be finished. We also need to finish the hook and mount designs. Liquid rubber?

1/14/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

We continued to work on the CAD design for the hang mechanism. We finished the drum mechanism and assembly and put it on the drive base. We also continued to work on the mount for the first stage I think. Hook designs are still in progress. We tested the first iteration of the 3D printed hook, and the mount on the hook broke. We decided that we should use Neo motors because they run the fastest, are the lightest and the gear ratio would be reasonable. We also realized that the aluminum tubes we were going to use would not give us much room to mount the constant force springs or the nylon spacers, we are now looking for other places to buy the stock from with a size of 2", 1.5" and 1 inch with 1/16 inch thick walls. McMaster had them but thy wouldnt come in in time (6-7 weeks), so we started looking for other places that sell the stock, but we haven't finished yet. It's mostly done concept wise, just needs some detail work now. We also made a decent weight calculator, and as of right now, the hang weight is sitting at around 7.5 to 8 pounds, including the three stages, mounts, drum and shaft assembly, hooks, and motors. We still need to include a couple spacers, gears for the motors, gearboxes?, and the strap. The weight of the three stages will also likely change if we switch to bigger tubes.

1/15/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Trevor W, Ben S

We received new insformation from the shooter team that we need the crossbar to be under 26 inches above the drivebase. In order to reduce the height, we removed the .375 inch spacer under the mount, we reduced the height of the bars by 4 (down to 23") and we reduced the overlap of the two stages from 4" to 2". We also need to increase the height of the hooks by a lot in order to still reach over the bar when it is at it's highest. We also continued to work on the hook design and make sure that they could be mounted to the bar. We also updated the Constant Force Spring mounting plates, allowing the arms to retract further (and not be as tall).1/16/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Trevor W, Ben S

We are working on fiinishing the total design of the robot, we made one arm a subassembly that way we could edit it on CAD better, we had a whole lot of ownership issues on cad but then we fixed them and we are currently trying to order aluminum for the actual assembly. We confirmed that the arm height wont be an issue with shooter, but the hooks might interfere with the shooter in a couple places. We need to put the assembly on the drive base, and put the two mounting brackets in the A012 assembly.1/18/2020

10:00am-12:00am

Attendance: Alex F. Nicole L, Nevin W, Nate S, Trevor W, Ben S

After integration, we received a list of things to work on. We modified the base mounting brackets to allow springs to be attached to the bracket and to the arm, so that when the arm moved, it would always center itself afterwards. We also designed a pivot for the hook and cross tubes that would allow them to pivot 180 degrees down at the start of the match, with the use of torsion springs. We also have decided on a single Neo 550 motor. We added the motor and gears to the assembly, but still need a mounting plate.

1/19/2020

10:00am-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Trevor W

We finished the hook design and started printing it, we put the strap in the AF Final Robot Assembly, and progress was made on the ratchet and paul mccartney. We attached the springs to the flip-up hook/worked on that assembly, we updated the shopping list, and we started doing shop drawings. We also figured out the superior way to eat a swiss roll and took a walk outside in the cold.

1/21/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

We received the printed Hook v3 with 100% infill, and tested it using the mount and a ~1.5" diameter bar. It was able to hold a person (who was heavier than a robot would be), so it should be enough. We also determined which parts would be made by Harris, and then began to work on the shop drawings for them. We almost finished the Ratchet and Pawl/Paul, we just need to make a mount for the servo. We made a mount on the third stage of the telescoping arm for the strap (though it isn't completely done), and began work on a mount to the drum.1/22/2020

5:00pm-9:00pm

Attendance: Alex F, Nevin W, Nate S, Ben S

We finished making Harris shop drawings so we can actually get our parts on time. We also fixed all of our assemblies which were broken for some reason. We finished the spacer the the strap would mount to at the top of the third stage, and began to work on the mounting for the motor. The motor assembly is basically broken and does not have a front mounting plate thing, so that makes things kinda difficult. We also more or less finished the mounting for the hook to the bar. We still need to actually make the holes to mount the motor and redesign the drum.

1/23/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

We finally have the motor actually mounted to something. The servo also has a mount, though the exact location is not known. We have continued work on the self-orienting hook mechanism, and put a new hook mounting plate in the hang assembly. We have also updated the shoppings list with a lot of the parts we need, but we still need to add a few more things. We added to the sheet of 3D printed parts we need. We also begun to update the parts and assemblies list with parts that are approved for shop drawings. We broke the drum assembly, so that needs to be fixed.1/25/2020

10:00am-12:00am

Attendance: anonymous person or persons

We focused primarily on getting shop drawings done so that people can start fabricating. We also finished up almost all of our Harris shop drawings, except for part P237 which Ben pulled so we could discuss whether we want the shaft to be higher up. This would allow our drum to be faster since it could be bigger. Other than that part, we completed A019 (the full winch assembly), including mountings for the servo, motor, gears, rachet and pawls, etc. The only thing we still need to add is a shaft collar and maybe a spacer to the motor so that the gear stays on. We also continued the process of adding things to the shopping list. We also sorted out some of the intereference issues with shooter and the battery box. We also began to revise the drum so that the strap could actually be attached to it, but need to continue.

1/26/2020

10:00am-9:00pm

Attendance: Alex F, Nicole F, Nevin W, Trevor W, Ben S

We primarily focused on making shop drawings for parts, and some of the parts were (probably) made in the shop. We also pretty much finalized the design, though there are still a very small number of things that need to be completed. We primarily worked on things from all subteams, not just Hang, so not much Hang-specific things happened. We did continue to update the assemblies, and fix any broken constraints. Some very small changes were made to the assemblies, such as adding spacers and threaded rods.

1/28/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W

We fixed a couple issues with shop drawings, such as a part not being made with the Harris template. We made the Drum bracket .125 inches thick instead of .063, and had to put in slots so the drum still fit. We also checked the assemblies to make sure there was no interference. We did discover that the arms are technically inside of the area where the ball will be shot, and the flange on the P101 CF Spring Bracket is slightly inside the stages, so the arms in practice will be a fraction of an inch taller, but it shouldn't be an issue. We also redid a couple shop drawings and continued fabricating parts, including some Hang parts (probably).

1/29/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nate S, Trevor W, Ben S

We have finished the design of the hang mechnism and have begun fabrication and painting for all parts. As Hang is second priority (behind drivebase), many of the Hang parts have been made or are in the process of being made, and will be painted soon. We have also printed a lot of our 3D parts (primarily spacers) and have started printing Hook v3. However, we may need to redesign the hook so that it is a bit taller and has more room to grab the bar.1/30/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

We continued the process of fabricating parts. The two 3x1" aluminum tube pieces that keep the motor and pawl in place are in the process of being made (one is done, the other just got started). Most of the Hang parts that were finished yesterday were also probably painted today, if they weren't already. We also have almost finished the Baring Blocks, we just need to run some sandpaper around the edges. We have also considered changing the design of the hooks a bit so that it can grab the bar easier, but we have not finished that.2/1/2020

10:00am-12:00am

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

We discovered that we needed to move the arms down in order to be under the flywheel of the shooter, which we accomplished by just shortening the length of the bars. We are still able to climb at the very highest point though. We began the assembly of the telescoping arms, and put together the top part that goes between the third stages. We also continued to work on the parts we need for Hang, such as the 3x1" tubes that hold the motor. We began to work on the UHMW plates, but need to continue. We got a lot of our 3D printed spacers back, but a lot of them were not made with the printer's tolerances in mind, and were too small and did not fit. Some were made to work, but several needed to be reprinted. In order to avoid confusion over their part number, we engraved the number into the spacer.

2/2/2020

10:00am-5:00pm

Attendance: Alex F, Nicole L, Nevin W, Trevor W, Ben S

We finished most of the parts for Hang, with the exceptions of the UHMW plates. We are considering redesigning them, so we held off on them. We began to assemble the Winch Assembly, but ran into a couple issues. First, we do not have P237 (the thing that holds the drum), so that entire thing can't be started yet. We also don't have the spacers that we need for a lot of the assembly, so we just have to ignore them for now. The tube the the motor mounts to is also not working, so the gears are too close together and can't mesh, and the motor is not secure enough. We also don't have the spring for the servo, so we need to get that. We also removed the paint from the second and third stages of the arms, since they need to slide nicely.

2/4/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

Trevor worked on the bill of materials, Nevin looked at 3D printed things, Alex worked on the UHMW plates (not yet finished, finished tomorrow?) and Nicole fixed the lengths of the stages and re-drilled holes in them (will finish tomorrow.) Since the spacers have finished printing, we can continue to assemble the winch mechanism. We are still waiting for the drum mounting brackets to come in, and we may need to redo one of the parts though. And since we have corrected the stages and will soon have the spacer, we will be able to continue to assemble the telescoping arms.

2/5/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Ben S

We continued to work on the UHMW plates, but we still need to tap the holes in them. We also finished drilling the holes in our stages, but due to not having parts, we were unable to assemble the arms. Currently, the only part we are missing are the UHMW plates, since the bottom slide plates just finished printing. Tomorrow, we will be able to assemble it. The winch is still a little ways off, since we need to remake P173 Motor Mounting tube to get the motor on the other side. We also are waiting on the Brass Inserts, which will be in on Saturday (hopefully). Until then, the drum can't be assembled.

2/6/2020

5:00pm-9:00pm

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

We finished the motor mounting tube and assembed the winch assembly again. We don't have a lot of the spacers for the winch, so we improvised. We currently just have it on a set of C channel with 1/4-20 holes at 1" intervals to simulate the drivebase. We tried to assemble the arms today, using all 3D printed spacers, but they shrunk a lot and did not fit inside the tubes, or the tubes did not fit inside them. We will print different ones in PLA though, and hopefully be able to assemble the telescoping arms.

2/8/2020

10:00am-12:00am

Attendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W

Today was the day we have all been waiting for, we assembled the telescoping arms. Well, like almost did, 80% of the way there. We filed the 3D printed spacers for an eternity and a half until they fit, did some jiu jitsu to get the constant force springs on the arms, decided to use some of thye UHWW plates, filed some more and then finally put a whole telescoping arm together. We are waiting on a part to be 3D printed so we didn't finish the other one, but are as far along as we can be. We also finished the winch (YAY!) and now just need to run the strap to the drums. We also made a mock drive base so we can do some basic testing before we put it on the robot. It was a busy day, but very productive.2/9/2020

10:00am-10:00pm

Attendance: Alex F, Nicole L, Nevin W, Trevor W

We continued the process of assembling the telescoping arms, and are about 95% of the way there now. We have both arms assembled, whith the spacers loctited in. The sensor mount is on and the top of the telescoping arms is almost done. We can't attach the hooks yet, since we don't have a finalized design and we don't want to print more until the design is final. We also got one of the P196 Bushing Spacers in the top, but the other one needs to be filed a bit more. After the spacer is in, we can put the top on and be more or less done with that part. We also need to put the Hook Retainer assembly on, but that isn't crucial right now. Programming won't care about it and since we don't have the hooks on, it won't be holding anything. Still, we should be able to put it on tomorrow if we have time. The winch assembly is also more or less complete, we just need to put the strap in the drum, and maybe a few other things.2/10/2020

5:00pm-10:00pm

Attendance: Alex F, Nicole L, Trevor W

We reassembled the Winch Assembly with the new spacers, so that the gears are fully engaged and the spring on the servo has enough room. We also finally put the telescoping arm assembly together. We attached the two arms to the Hang Top assembly, though we don't have the Hook Assembly yet. We also assembled the Hook Retainer Assembly and put it on the arms, but we don't know exactly where it needs to go yet since we don't have a final hook design. It clamps in place, so we can move it up and down pretty easily. Tomorrow, we should be able to put the Winch and Telescoping Arm assemblies onto the robot (if Electrical/Programming allow us). Putting the winch on just requires placeing over the holes and then putting 4 bolts in. The arms are a bit harder, but all of the hardware is together (I couldn't find any .5" spacers in the shop closet, so we will print more unless we find them) so it shouldn't be too difficult. We are also printing more spacers so that the Hook Retainer plates don't bend when clamped on.

2/11/2020

5:00pm-10:00pm

Atttendance: Alex F, Nicole L, Nevin W, Nate S, Trevor W, Ben S

We began the process of putting the hang mechanisms on the robot. We poke holes in the straps with soldering irons, and we able to clamp them into the drum. We were also able to put the drum onto the robot. We tried to get the telescoping arms on, but had trouble getting the spacers and rollers onto the shoulder bolt. We still have a couple things we need to do though. We ran into a couple issues with the Hang top assembly, such as the horizontal bar not rotating freely. Currently, the lexan is not strong enough to overcome the friction from the paint, so we need to file/belt sand the bar so it slides better. In addition, when pivoting the crossbars up with the torsion springs, they don't return to be exactly parallel to the ground, and instead pivot about 200 degrees total. In addition to those issues, there is also a snag in one of the second stages that slows it down a bit. Our springs on the telescoping arm mounts are also way too strong, so we need to order better ones.

2/12/2020

5:00pm-10:00pm

Attendance: people on hang including, but not limited to, Nicole, Nevin, Nate, Alex F

The hook was completed (for real this time I promise) so now it can both hook onto the switch easily and not collide with the shooter. The hook retainer bar should be moved down on the assembly to accomodate the improved hook.design. We also [...]