2022:Intake: Difference between revisions

Mechanical1 (talk | contribs) No edit summary Tag: visualeditor |

Mechanical1 (talk | contribs) No edit summary Tag: visualeditor |

||

| Line 19: | Line 19: | ||

[[File:Lexan Panel.png|thumb]] | [[File:Lexan Panel.png|thumb]] | ||

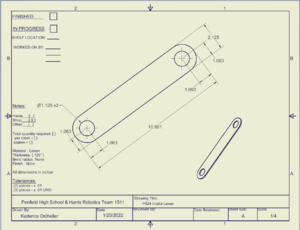

After making a shop drawings for the intake to get dimensions, we began to build our current CAD model in the shop. We cut out four pieces of 2.125"x10.801" Lexan to use as our side panels. After that, we remounted the axles on the Lexan and made a tensioner for the belts on the intake. | After making a shop drawings for the intake to get dimensions, we began to build our current CAD model in the shop. We cut out four pieces of 2.125"x10.801" Lexan to use as our side panels. After that, we remounted the axles on the Lexan and made a tensioner for the belts on the intake. | ||

== CAD/Testing 1/22/2022 == | |||

First thing this morning, our storage and intake teams worked on modelling our prototype after our new CAD module. After making adjustments (shifting the storage axles closer together, securing the angle of the intake pieces, belting the storage and intake together, etc), we were able to get a consistent and successful cargo path into the hypothetical shooter (shooter was not attached to our cargo pathway prototype)! At the same time, we had more cargo members working on CAD and calculations. We created a new CAD model in Inventor with more accurate pieces, materials, and dimensions, taking the hang space needs into high consideration. We used the information we had to start to do piston calculations. In order to determine the length of our stroke and the bore, we had to find the center of gravity and the torque using an excel spreadsheet and formulas. We used the necessary PSI (50 lbs/in^2) to find the force we needed to apply by the piston and plan to pick up where we left off tomorrow. | |||

Revision as of 20:57, 22 January 2022

Leaders: Nick V. and Kadence O.

Prototyping 1/9/2022-1/12/2022

Right after kickoff, we divided into groups and started brainstorming intake ideas. We looked over all of our ideas and found the common denominators between all of the designs; over the bumper intake designs and using wheels (either single axil or double axil). Since we decided on a swerve we drive base, we knew that cutting into the bumper would force us to compromise overall stability- something our strategy team determined was very important. We thought that a double axil could help guide the ball to storage and it might be beneficial in getting it over our 6" (off the ground) bumper. Next, tested each wheels impact on the cargo and discovered that compliance wheels worked the best. Finally, we launched into prototyping and set up a to-scale drive base with a bumper for reference. We prototyped both 4" and 2" compliance wheels of different densities and decided on 2" black compliance wheels and then made sketches and a 3D CAD model to help us determine the height of the intake.

Prototyping 1/13/2022

Today, we picked up where we left off and went back to the CAD drawing, adjusting angles and measurements as we learned more information. After finding out that 9.125" from the ground to the center of the axil and 10.625" from the inside of the bumper to the center of the axil, we began to create more accurate dimensions based on our strategy teams long/skinny robot goal. We estimated that the front of our robot would be roughly 22" (not including bumper), so we reduced the intake to 16" and tested it. Once we got that working, we worked very closely with the storage team and integrated our ideas together, working on a way to transfer the cargo from intake to storage. we decided on a funnel, made from a Lexan-like plastic and began prototyping. We are still trying to get the right angle/arc for the funnel.

Prototyping 1/15/2022

Picking up where we left off, we integrated the storage mechanism into the intake using a second axle with 2"compliance wheels to transition the cargo, 14.5" from the ground to the center of axle and 4" from the inner bumper to the center of axle. We also attached Lexan near the first axle in order to keep the ball low and control the parabola oriented arc. Next, we stabilized the intake mechanisms at the correct lengths and orientations relevant to the storage, and tested the intake, picking up the ball from multiple angles and positions. All of our tests were done while the robot was moving, rather than feeding into the robot, to give us more accurate results.

Prototyping 1/16/2022

Today, we decided to integrate the intake, storage, and shooter mechanisms in order to make sure the systems fit together. First, we needed to do a rough robot real-estate, so that we could determine the sizes of our mechanism. Through CAD/Inventor testing, we found that the mechanisms were able to work together well with a intake width of 16" (outside to outside). Next, we determined belt width and tooth sizes for our intake pulleys and put them in the team shopping cart. The rest of the day was spent doing shooter to storage integration.

CAD 1/19/2022

After a team integration to get everyone on the same page, cargo joined as a group to assemble our prototypes in CAD in order to figure out how to retract intake and what angle storage/shooter will be in order to maximize space efficiency. We each made separate assemblies for each mechanism and then placed them in a drive base assembly. Once the intake, storage, and shooter were all in one assembly, we were able to properly constrain and align the mechanisms to what we believe is the most beneficial positions. By placing the storage 48.82 degrees from the top of the drive base and by setting the intake pivot point to the top of the storage, we were able to retract the intake into the frame perimeter. Tomorrow, we will try to assemble this complete cargo pathway using the tools in our shop and see if all of our dimensions are still accurate.

Testing 1/20/2022

After making a shop drawings for the intake to get dimensions, we began to build our current CAD model in the shop. We cut out four pieces of 2.125"x10.801" Lexan to use as our side panels. After that, we remounted the axles on the Lexan and made a tensioner for the belts on the intake.

CAD/Testing 1/22/2022

First thing this morning, our storage and intake teams worked on modelling our prototype after our new CAD module. After making adjustments (shifting the storage axles closer together, securing the angle of the intake pieces, belting the storage and intake together, etc), we were able to get a consistent and successful cargo path into the hypothetical shooter (shooter was not attached to our cargo pathway prototype)! At the same time, we had more cargo members working on CAD and calculations. We created a new CAD model in Inventor with more accurate pieces, materials, and dimensions, taking the hang space needs into high consideration. We used the information we had to start to do piston calculations. In order to determine the length of our stroke and the bore, we had to find the center of gravity and the torque using an excel spreadsheet and formulas. We used the necessary PSI (50 lbs/in^2) to find the force we needed to apply by the piston and plan to pick up where we left off tomorrow.