2024:Mechanical: Difference between revisions

Programming (talk | contribs) |

Mechanical1 (talk | contribs) |

||

| Line 21: | Line 21: | ||

<span style="font-size: 14pt;">Work Completed:</span> | <span style="font-size: 14pt;">Work Completed:</span> | ||

<span style="font-size: 12pt;">Hanging Mechanism</span> | <span style="font-size: 12pt;">Hanging Mechanism</span> | ||

**** | ***** | ||

<span style="font-size: 10pt;">Prototyped two different types of hooks</span> | <span style="font-size: 10pt;">Prototyped two different types of hooks</span> | ||

**** | ***** | ||

<span style="font-size: 10pt;">Tested both, worked well in holding on the chain and preventing slipping</span> | <span style="font-size: 10pt;">Tested both, worked well in holding on the chain and preventing slipping</span> | ||

| Line 31: | Line 31: | ||

<span style="font-size: 14pt;"> | <span style="font-size: 14pt;"> | ||

<span style="font-size: 12pt;">Game Piece Manipulation</span></span> | <span style="font-size: 12pt;">Game Piece Manipulation</span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

<span>Started prototyping gripper for trap outtake</span></span> | <span>Started prototyping gripper for trap outtake</span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

| Line 42: | Line 42: | ||

<span style="font-size: 12pt;"> | <span style="font-size: 12pt;"> | ||

<span>KitBot</span></span> | <span>KitBot</span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

| Line 54: | Line 54: | ||

<span> | <span> | ||

<span style="font-size: 12pt;">Drive Base</span></span></span> | <span style="font-size: 12pt;">Drive Base</span></span></span> | ||

*** | **** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

<span>Continued assembly on Swerve Drives.</span></span> | <span>Continued assembly on Swerve Drives.</span></span> | ||

*** | **** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

<span>Worked on CAD for Drive Base:</span></span> | <span>Worked on CAD for Drive Base:</span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

| Line 68: | Line 68: | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

<span></span></span> | <span></span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

| Line 74: | Line 74: | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

<span></span></span> | <span></span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

<span>AndyMark C-channel frame (24.250in. x 24.250in.)</span></span> | <span>AndyMark C-channel frame (24.250in. x 24.250in.)</span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

<span>Support frame pieces</span></span> | <span>Support frame pieces</span></span> | ||

**** | ***** | ||

<span style="font-size: 10pt;"> | <span style="font-size: 10pt;"> | ||

| Line 114: | Line 114: | ||

*Continued to CAD the shooter/intake mechanism and figured out some geometries/measurements | *Continued to CAD the shooter/intake mechanism and figured out some geometries/measurements | ||

*Worked on assembling prototype of mechanism | *Worked on assembling prototype of mechanism | ||

1/14/24 (continued) | |||

All 6 frame rails sections were cut. Frame will be 27.25" wide x 27.25" long. Top of frame rail is 3.75" off the ground. Top of motors are 8.23" off the floor. Bottom edge of bumpers will be 0.5" off the floor. The 2 interior supports will be located 6.5" in from the frame outside perimeter. The internal "C" channel pieces will file inward. Next steps: 1)drill four holes in each of the front and rear frame sections. Trevor will provide a fab drawing. 2) assemble frame with Andy-Mark "C" channel blocks. 3) Will plan bolt orientation head on the bottom to minimize bottom protrusions. 4) Paint frame black. Check for paint availability. | |||

Swerve modules need final assembly. Next steps: 1. Clean steering motor shaft and pinion bore. Loctite with 609 Green. Coat both surfaces and assembly with a twisting action. Final height is .125" past end of the motor shaft. 2) Marry the motor plate to the body subassembly using 10-32 screws with blue thread locker and stand off spacers. | |||

= Archives = | = Archives = | ||

Revision as of 15:25, 15 January 2024

Daily Status

1/6/24

Work Completed:

Hanging Mechanism

- Discussed and prototyped on CAD a spring gate hook

Game Piece Manipulation

- Split into two groups: intake/outtake

- Intake developed prototype with two rows of wheels

- Outtake developed a slingshot/crossbow mechanism

- Discussed ideas for "Trap" outtake; expanding gripper- prototype tomorrow!

KitBot

- Took inventory of the parts received from AndyMark

- Started building the bot from the instructions, had to modify multiple parts to fit into the frame correctly

- Almost finished assembly, just a few more items to finish

1/7/24

Work Completed:

Hanging Mechanism

Prototyped two different types of hooks

Tested both, worked well in holding on the chain and preventing slipping

Game Piece Manipulation

Started prototyping gripper for trap outtake

Two prototypes for trap: expanding gripper and "anti-chopsticks"

KitBot

Working on assembly, projected to be done on Tuesday

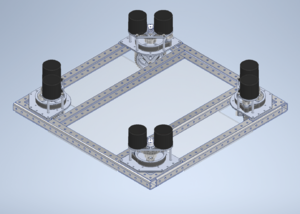

1/11/24 Drive Base

Continued assembly on Swerve Drives.

Worked on CAD for Drive Base:

Mk4 Swerve drive modules

Lexan belly plate

AndyMark C-channel frame (24.250in. x 24.250in.)

Support frame pieces

L-brackets

1/13/24;

Drive base

- Continued assembly of swerve drive modules

- Encoders arrived so we could resume working on the swerve drives

- Changes size of our CAD drawing from 24.250in.x24in. to 27.250in.x24in.

- Made CAD designs for:

- Sponsor Panels

- Sponsor Panel supports

- Drive base side panels

- Flat frame panels

1/14/24

Game Piece Manipulation:

- Continued to CAD the shooter/intake mechanism and figured out some geometries/measurements

- Worked on assembling prototype of mechanism

1/14/24 (continued)

All 6 frame rails sections were cut. Frame will be 27.25" wide x 27.25" long. Top of frame rail is 3.75" off the ground. Top of motors are 8.23" off the floor. Bottom edge of bumpers will be 0.5" off the floor. The 2 interior supports will be located 6.5" in from the frame outside perimeter. The internal "C" channel pieces will file inward. Next steps: 1)drill four holes in each of the front and rear frame sections. Trevor will provide a fab drawing. 2) assemble frame with Andy-Mark "C" channel blocks. 3) Will plan bolt orientation head on the bottom to minimize bottom protrusions. 4) Paint frame black. Check for paint availability.

Swerve modules need final assembly. Next steps: 1. Clean steering motor shaft and pinion bore. Loctite with 609 Green. Coat both surfaces and assembly with a twisting action. Final height is .125" past end of the motor shaft. 2) Marry the motor plate to the body subassembly using 10-32 screws with blue thread locker and stand off spacers.