2024:Drive Base: Difference between revisions

From 1511Wookiee

Jump to navigationJump to search

Mechanical1 (talk | contribs) No edit summary |

mNo edit summary |

||

| Line 28: | Line 28: | ||

We still need to finish and mount the following: | We still need to finish and mount the following: | ||

*Fabricate the bed pan- this will house all of the electrical panels and other items to small for the C-Channel | *Fabricate the bed pan- this will house all of the electrical panels and other items to small for the C-Channel | ||

Build a moveable plate for the hang- this plate will be most likely be | |||

---- | |||

<span style="text-decoration: underline;">'''1/20/24:'''</span> | |||

Finished CAD Models: | |||

*P059- Swerve Dust Covers | |||

*P058- Bed Pan Spacers 1.125in. | |||

Main Drivebase CAD: | |||

*Attached dust covers | |||

*attached bed pan spacers | |||

*attached the new/updated | |||

Drivebase: | |||

*Greased the 4 swerve modules | |||

*Gave base to electrical, they got the robot wired and started letting Robot Control Systems run calibrations and tests on the drivebase | |||

Looked into/to do: | |||

*Looked into how to mount the bumpers | |||

***Ideas: | |||

***Using Quick release pins with cotter pins | |||

***using a pin that slides into the side of the C-Channel then drop pins in the top with spring steel holding the pins down | |||

---- | |||

<span style="text-decoration: underline;" >'''1/21/24:'''</span> | |||

Revision as of 18:48, 20 January 2024

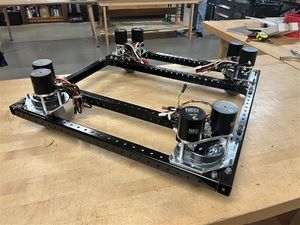

Drive base status

1/18/24:

We have a drive base!!

Information:

x4 Mk.4 swerve modules (Neo motors)

x4 25in. side bars

- x2 bars for the outside of the frame

- x2 as support/additional mounting bars in located in the middle of the drive base, the bars also serve as protection for the swerve modules preventing damage to our brand new motors

- From outside bar to outside bar it is a 6.5in offset

- The offset on the inside is 12in. from inside bar to inside bar

x2 27in. horizontal bars, act as end caps'

x8 Andymark Corner Brackets (picture)

-

We still need to finish and mount the following:

- Fabricate the bed pan- this will house all of the electrical panels and other items to small for the C-Channel

Build a moveable plate for the hang- this plate will be most likely be

1/20/24:

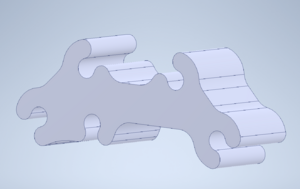

Finished CAD Models:

- P059- Swerve Dust Covers

- P058- Bed Pan Spacers 1.125in.

Main Drivebase CAD:

- Attached dust covers

- attached bed pan spacers

- attached the new/updated

Drivebase:

- Greased the 4 swerve modules

- Gave base to electrical, they got the robot wired and started letting Robot Control Systems run calibrations and tests on the drivebase

Looked into/to do:

- Looked into how to mount the bumpers

- Ideas:

- Using Quick release pins with cotter pins

- using a pin that slides into the side of the C-Channel then drop pins in the top with spring steel holding the pins down

1/21/24: