2021:Power Cell Intake

Design Summary:

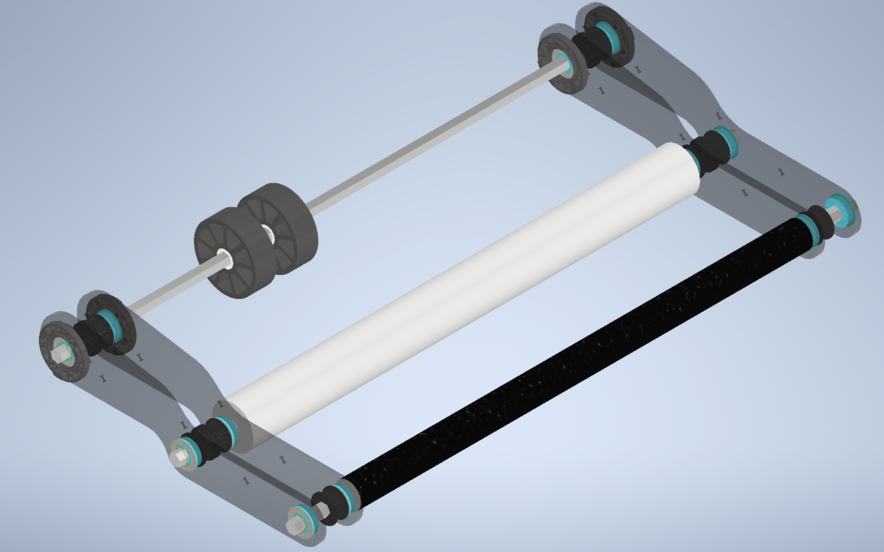

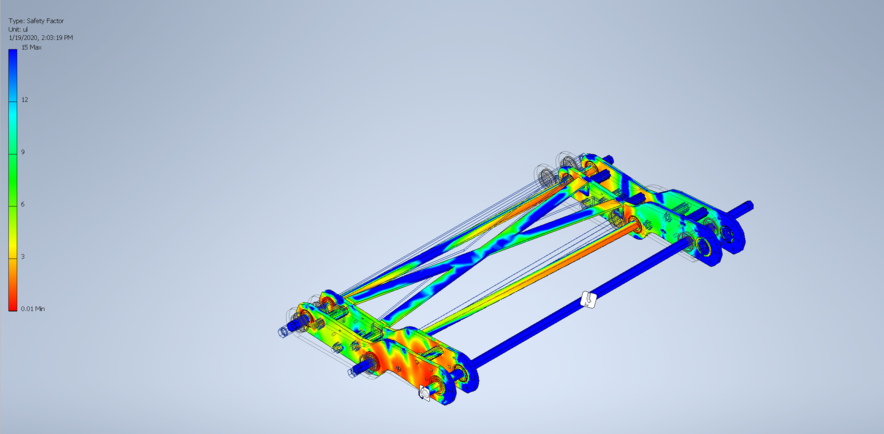

- Single roller system. A roller of 3D printed left mecanum wheels (2" diameter) pivot down to grab balls and redirect the balls along the bumper into a cut in the frame, where they are indexed by a beam break sensor that counts the balls as the enter the robot. The handoff from the intake to the helix is two compliance wheels on the same axle as the pivot that pull the balls into the helix. The rollers are powered by a NEO 550 @ a 16:1 gear ratio and the pivot is powered by a NEO 550 motor @ a 100:1 gear ratio.

Prototyping 1/5/2020-1/11/2020

Overview: Based on initial team brainstorming and sketching, as well as theinformation from Strategy Subteam, we determined to prototype:

- An over-the-bumper intake:

- A thru-the-bumper intake

This decision is critical as it affects Drive Base!

- Test using various componenets touching the balls:

- Test brushes

- Test wheels

- Test "hot dog roll" - a material wrapped around a rod that grips the game piece well and will snag it.

- Test mecanum wheels to direct the balls into the robot in a manner that can be counted or indexed.

- Combinations

Observations: We observed the following over the course of prototyping:

- It is not difficult to get the balls to go over the bumper.

Decisions:

- Intake will pivot out of the front of the robot

- Intake will be full width (relatively) of the robot

- Larry, Tom C., and Kyle discussed the pros and cons of having the balls go over or through the bumpers. Pros for a design that takes the balls over the bumpers included a simpler design that has more integrity. Pros for a drive base frame cut for the balls include a funnel that would only allow for one ball to enter the robot at a time, vastly decreasing the chance that we intake more balls than we want. Drive base cut also makes sensor placement to count the balls better. After the discussion, we decided on making a cut in the drive base frame for the intake, and the cut will be 8-9 inches wide.

Working towards a design that will extend the intake mechanism out of the frame perimeter and put it back in. Four bar design similar to 971's 2019 intake.That design would put us over the frame when the intake is stored.- Intake deploy is currently motor-driven and rotates the intake mechanism 90 degrees around a pivot point just above the frame.

- Decided on the foam roller + mecanum redirect bar design.

- Prototype is complete! Mecanums redirect the ball very well, experimented with wheel spacing, axle height from ground, mecanum axle distance from the frame perimeter, etc.

Need to do (as of 2/13/2021):

- Put the Camera Mount on the robot at some point

- Assemble the mecanum wheels, and put on the robot

- Replace transition wheels with mecanums

- Replace current intake blades with the new ones

- Put the hard stop and banner sensor mounts on the robot once they come back from Harris

Design details

- From the prototype we got running at 1/11/2020, here are the measurements that allow for the mecanums to redirect the ball to the center

- Distance from the floor to the mecanum bar: 6.625in

- Distance from frame perimeter to the mecanum bar: 3.9375in

Distance from frame perimeter to hot dog roller: 9.5625in- hot dog bar is no longe rin use

Distance between mecanum axle to hot dog axle: 5.625in- hot dog bar is no longer in use

- Distance from floor to the bottom of the bumper: 1.5in

- Distance from floor to center of handoff wheel axle: 8.125in

- Distance from frame perimeter to center of handoff wheel axle: 1.75in

- On 1/12/2020, we experimented with a different hot dog roller which gave us better results. New roller is a 1.25in in diameter roller covered in surgical tubing rubber instead of foam.

- New roller is still grippy enough to grab the balls but it's more slippery and prevents binding between the two rollers. Easier to outtake balls as well.

- 1/14/20 - 1/16/20: ran into a load of issues. Previous iteration was hitting the helix and the centered cut out couldn't handle two balls being intaked at once. Currently testing a design where the bumper cut is to the left of the robot frame if youre looking at the robot from straight on, same side as the shooter. Currently making the prototype to test this new design but waiting on more mecanum wheels to print since the last print failed. Nick V, AJ L, Chris S, Ben D, and others have all worked on the CAD for the pivot mechanism which will be run by a NEO according to our calculations. The same motor will also run the intake --> helix handoff compliance wheel (3green) in a manner similar to our 2016 scalar where the same motors were running the pivot and the movement of the telescoping arm. Lots of work to be done still.

- 3D Printed Hubs are in the left direction!

- Offseason of 2020: in preparation for the upcoming competition, which we knew would require the 2020 robot, we looked at ways to improve the robot, in particular the intake. We made a list of issues with the intake, and decided that it would require large changes to improve it in a significant way. We looked at lots of successful teams in 2020 who had robot reveals that showed off their intake or competed in a Week 1 regional. We analyzed why their intakes worked as well as they did, then used that to create a list of modifications we could consider making to the intake to improve it's performance. These improvements included removing the hot dog bar, adding vertical and horizontal flex, and making the axle mounts drop down. The hope is that a combination of these changes would allow our robot to intake balls faster and more consistantly, with less balls getting stuck in the transition, bouncing off, or otherwise not going in smoothly.

- Our current layout has no hot dog bar, and the outer (?) intake blade on the left side of the robot has been removed. We have redesigned the intake blades with a better belt layout, to prevent rubbing on the bumpers. We have made several other modifications but I really can't remember.

2021 Daily Diary:

Kickoff to 1/16/2021

We modified and re-ranked the priority list we made during Preseason based on the Challenges. We made general decisions on what we wanted to do to intake (including testing the removal of the hot dog bar, removing the Peace Bridge, etc.). We also established who would be leading intake, and began to divy up the work.

1/19/2021

7:00 PM - 9:30 PM (VIRTUAL)

We had a wonderful day of downloading the Robot CAD, and absolutely nothing went wrong.

We each worked on different things, with Alex F. working on the camera and ring light mount, Nicole working on the Intake plates, and Alex Leete working on the sensors.

Camera mount: We got a vision cone for the camera made and placed in the CAD to get a general idea of what the mount needs to look like.

Intake Plates: things happened????

New sensor mounts: ????

1/21/2021

7:00 PM - 9:30 PM (VIRTUAL)

We got a rough draft of the camera and ring light mounts, despite not having a 3D model of either and not even knowing what ring light we used, despite looking seemingly everywhere. The mounts are based on the 2019 ones though, so it should work (?). We also continued to do intake plate and sensor mount stuff probably?

1/23/2021

10:00 AM - 6:00 PM (IN PERSON)

We did some testing in the commons, mostly the shooter but a little bit of intake as well. There were some issues, primarily with the ball getting stuck on the transition between intake and helix, but this might be changed with the Rainbow bridge being removed? The camera mount was modified a little and approved by Roseanne, hopefully those will be printed soon (although we also want to add some adjustability to them at some point). The intake plates also had stuff done to it??? The sensor mounts were nearly finished I think.

1/26/2021

7:00 PM - 9:30 PM (VIRTUAL)

We did get the task list and wiki updated, and the sensor mounts are done (but still need to be approved and made and stuff). Nicole briefed Kadence on the intake plates since Nicole will probably be in the commons testing next meeting instead of doing CAD.

1/28/2021

7:00 PM - 9:00 PM (not 9:30 as I learned too late) (IN PERSON)

We have started making new Helix brushes so we know that the new ones aren't causing the jamming, and also to make minor improvement. Someone might have gotten a little snipper happy with one of them, but I'm sure it will be fine. And unfortunately Nicole didn't get to clean the brushes up :(. Once Nicole updates the wiki, there won't be a bunch of underscores and question marks in the following sentence I hope. We also finished the intake plates, and started _____????????

1/30/2021

1:00 PM - 6:00 PM (IN PERSON)

Today was a testing/driving day, so not much work was done. However, we did get a finished print of the Intake Camera Mount and Intake Ring Light Mount (I'm still not sure if that should be one or two words). Whatever idiot designed it didn't put any thought into how it would actually fit together, but luckily it works. Of course the camera mount still needs to be reprinted at some point, since the holes are slightly bigger than they should be, thanks to the same idiot. Thank god they aren't a subteam co-lead or drive team member or anything, just imagine if that was the case. We did use the intake while driving, and it still had trouble on the transition from intake to helix on around 1 out of every 3 balls, and someone would just have to kick it. We think it is due to the helix brushes being too short there, so hopefully after the new ones get finished and installed we won't have that problem as much.

2/2/2021

7:00 PM - 9:30 PM (VIRTUAL)

The new sensor mounts were unfortunately not made with the sheet metal starting point, so we remade them. Roseanne had some trouble opening the updated ones, so she will check those over and they will be changed if there are any issues.

2/4/2021

7:00 PM - 9:00 PM (IN PERSON)

The new camera mount was printed with the correct size hole, and that's pretty much where the good news ends. They printed with the opening about .03 inches smaller than they should be, so when they were forced on, the mount snapped. The ring light also snapped. We tried to zip tie them but that didn't work either, so we ended up just velcroing the camera to the helix ring, and that will keep the camera on for all of 5 seconds. Even if the mount did fit, there isn't a way to actually drill the holes without having to totally remove the helix ring. In summary, a pretty major redesign of both mounts is required, so yay I guess. Now I'll pass the mic to Nicole so she can talk about what she did. take it away captain

2/6/2021

1:00 PM - 6:00 PM (iN PERSON)

On a positive note, we finally have the intake fixed and working properly (yay!). Between removing the zip tie pushing on the ball, lengthening the brushes, and adding some stiffness to the intake, we had pretty much 0 issues testing today. In addition, both the new sensor mounts and the camera mount were addded to the Final Robot Assembly, and the camera and ring light mounts v2 started printing. Of course, programming also mentioned that they had no intention of using any camera or ring light for autonomous, so you win some you lose some I guess. Oh well ¯\_(ツ)_/¯. Meanwhile, we also did some work in the shop, but as Alex Fabrizi has no idea what they did, Nicole needs to add this information.

2/9/2021

7:00 PM - 9:30 PM (VIRTUAL)

We mostly worked on submission things, so not much work was done on intake or anything. It was mostly just reading over things and making sure info is accurate and we have good pictures of everything.

2/11/2021

7:00 PM - 9:00 PM (IN PERSON)

We have a printed version of the camera mount and ring light mount, but we still need to decide if it will be used. The ring light won't be, but if Drive Team still wants the camera, we may need to use the mount. We also continued to work on the intake blades, and hopefully things happened and someone who knew what happened would be able to fill this in. We also made Harris Shop Drawings for all of the Harris parts so far.

2/13/2021

1:00 PM - 6:00 PM (IN PERSON)

During Drive Practice, we did some intake testing. We have sent out the hardstops to Harris, but obviously they haven't come back yet, so the intake was rubbing on the bumper, and actually destroying the top of the numbers. We added some tape to the bumpers, so now that is being destroyed instead of the bumpers. We also put a little bit of a pool noodle under the intake to act as a "hard" stop. As of right now, the intake is working pretty well. There was one time that we tried to intake like 3 balls at once, and two balls got stuck in the transition behind the wheel, but this was solved by outtaking. We never saw it happen again, so we just gonna assume it's all fine. There was a little bit of shop work done, but I don't think any of it was intake related.