2022:Hang

List of Hang Things to Do

- Starting Configuration

- If fully back will it fit?

- If it does fit in frame, does it reach?

- Crossbars

- Lowest @ switch to static high

- How many pistons

- Piston things (Ask Nicole, I can't read her handwriting)

- Winch Width with crossbar length

- Hook

- Easy on/off, hold on bar, hook bar

- diameter of hook fits bar

- Stoeckl hooks??????? flipping one.

- Static hook

- What mech. brings it back?

- Spring, gas shocks

- What mech. brings it back?

- Moveable arm

- Bring back with slow release

- Valve on pistons

- Bring back with slow release

1/11/2022-1/12/2022

We created a very rough prototype for the hang mechanism, which was a model box to represent the robot. Cinderblocks were added to show the weight the robot will eventually be. This model was used to perform various tests.

01/13/2022

Attendance: Jacob, Nicole, Marisa, Trevor (Ishan), Audrey

We created our hang prototype. Our prototype consists of 2 different types of arms that are either vertical or angled in order to grab the high and traversal bar. One set of arms is stationary with hooks that latch over the bar. The second set extends and pivots in order to grab the next highest bar. We prototyped both bars at half scale and will test the swinging motion Saturday.

1/15/2022

We had a big discussion with the rest of the team and described how we are going to work hang. It will have a set of 2 bars that will only move forward to offset the weight of the robot to keep it from swinging and have two arms that will reach out and grab the bar to retract by means of a spring. Both arms will pivot on the same point and will be connected by spring to bring them back to each other.

https://drive.google.com/file/d/1M5uRVabg985dc4unzzd82pxbcvFIgSxI/view?usp=sharing

https://drive.google.com/file/d/1CO84FIwgVk7WRuRb0i689V2kZs68EaTK/view?usp=sharing

1/18/2022

We had a group discussion about robot real estate and what we needed to determine in order to continue. We continued with a lot of math to determine the necessary lengths of the arms.

1/19/2022

We worked in two groups, one of which worked on CAD-ing the winch assembly with the disk break and the other making a hang assembly. Group one modified our winch assembly from 2020 and added our disk break with calipers from 2018. After creating a new disc break and new parts to mount the calipers, we are almost done with the assembly. Group two assembled a CAD hang using the arm lengths we determined yesterday.

1/22/2022

Today, we stayed in our two groups, finishing what we started yesterday. Group one continued our winch assembly and group two focused on the arm assembly and piston calculations. We've set arm lengths and have an assembly with both the static and telescoping arms and the winch on the way. We also did calculations and set up an excel sheet to determine the stroke length needed for our rotational piston. After some revelations at integration, we have a long to-do list of things to modify, including the ways our arms will snap together and the mounting of our disk break.

1/23/2022

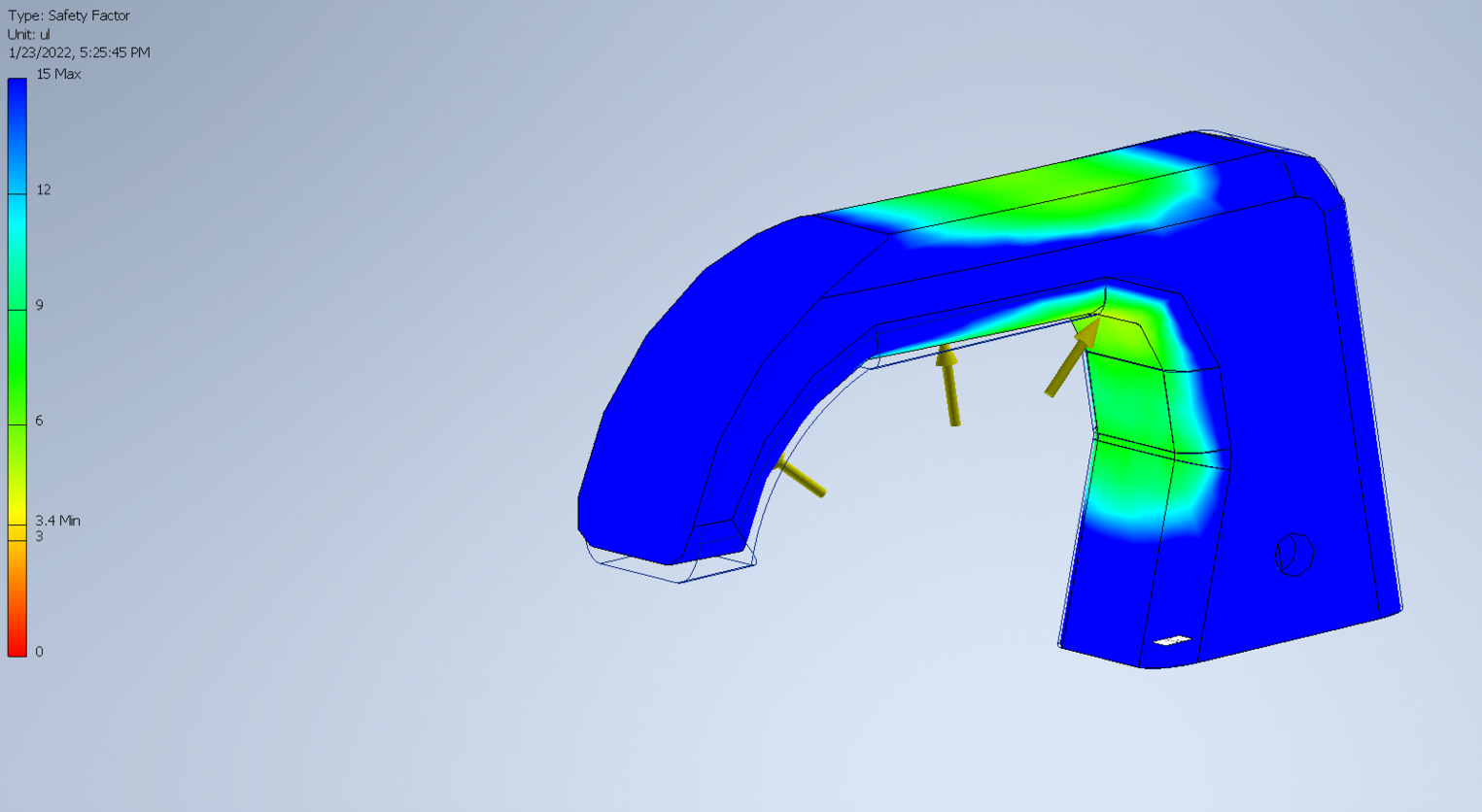

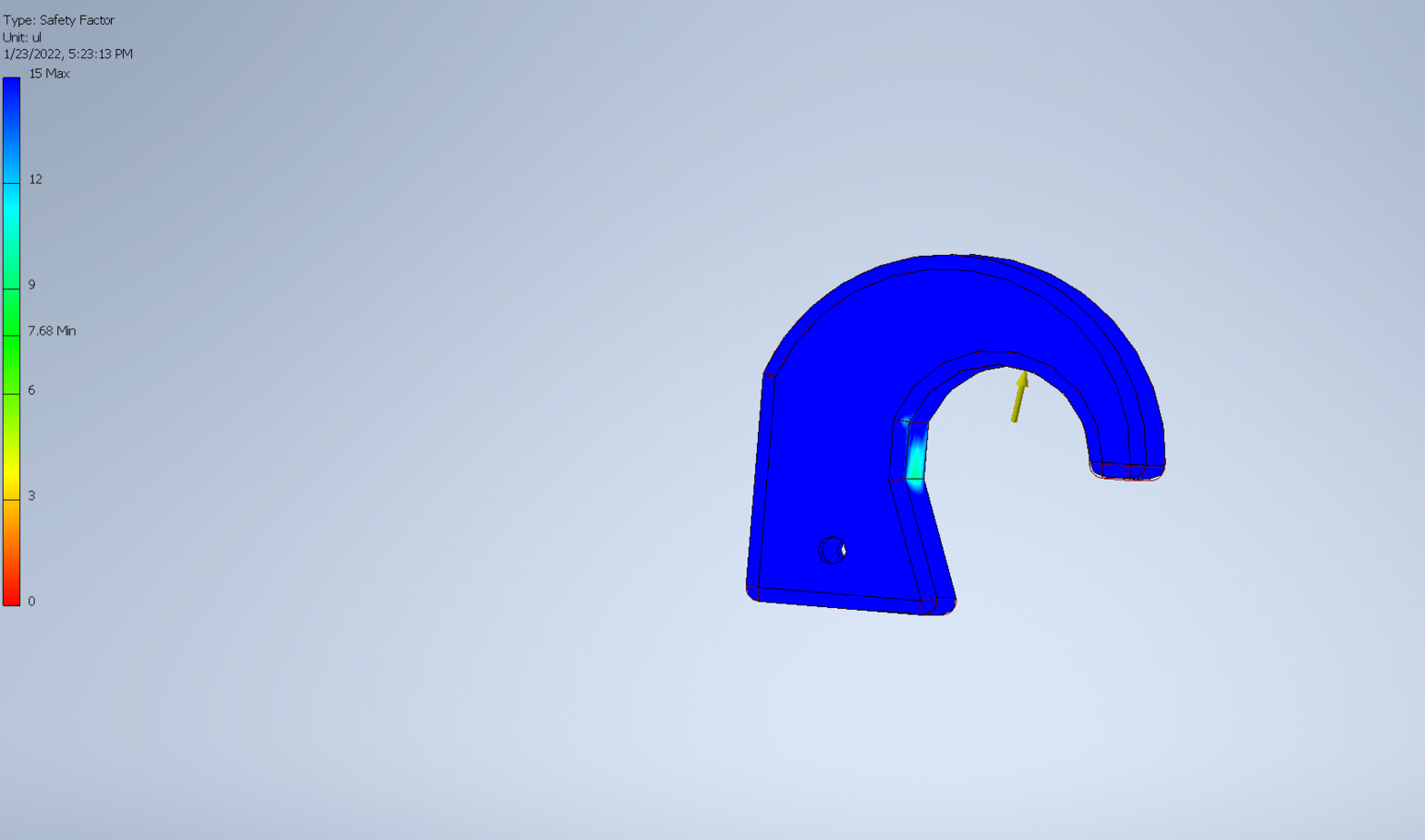

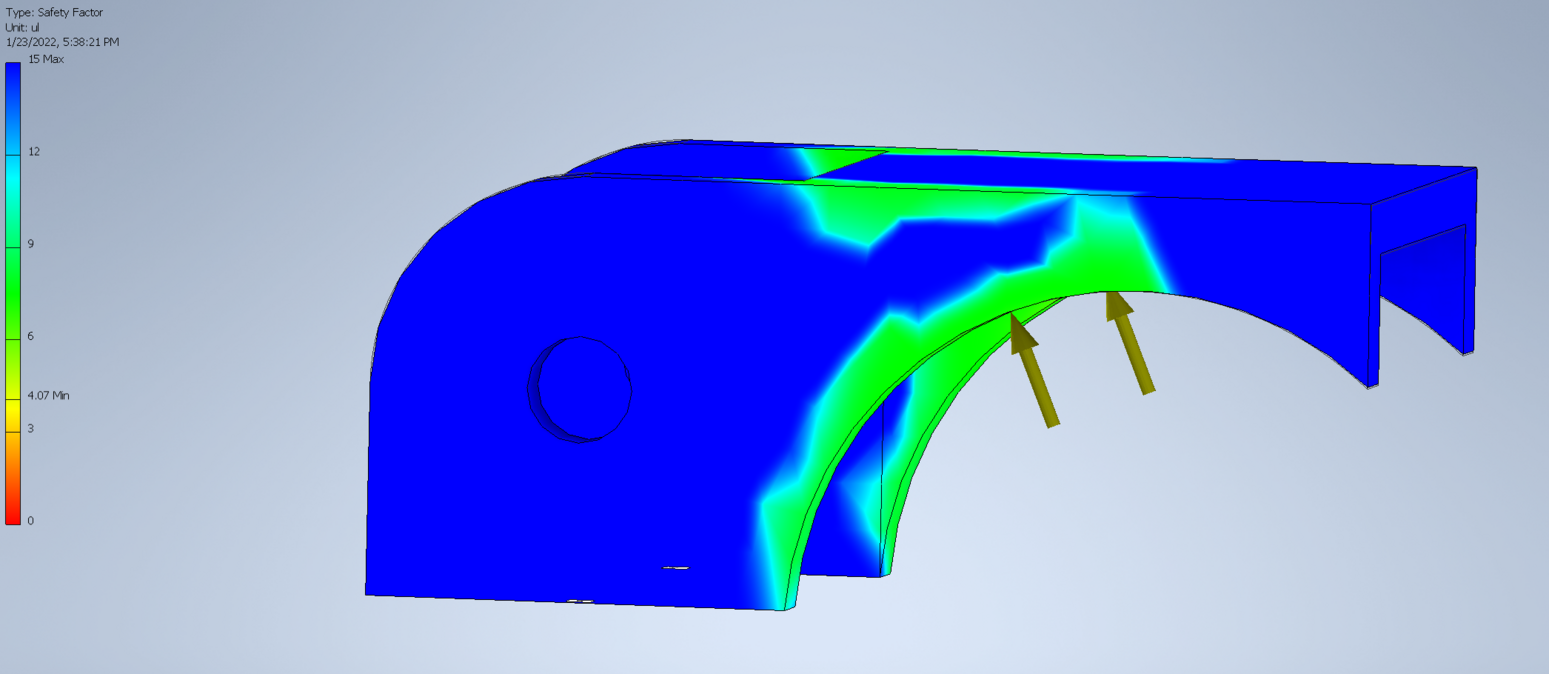

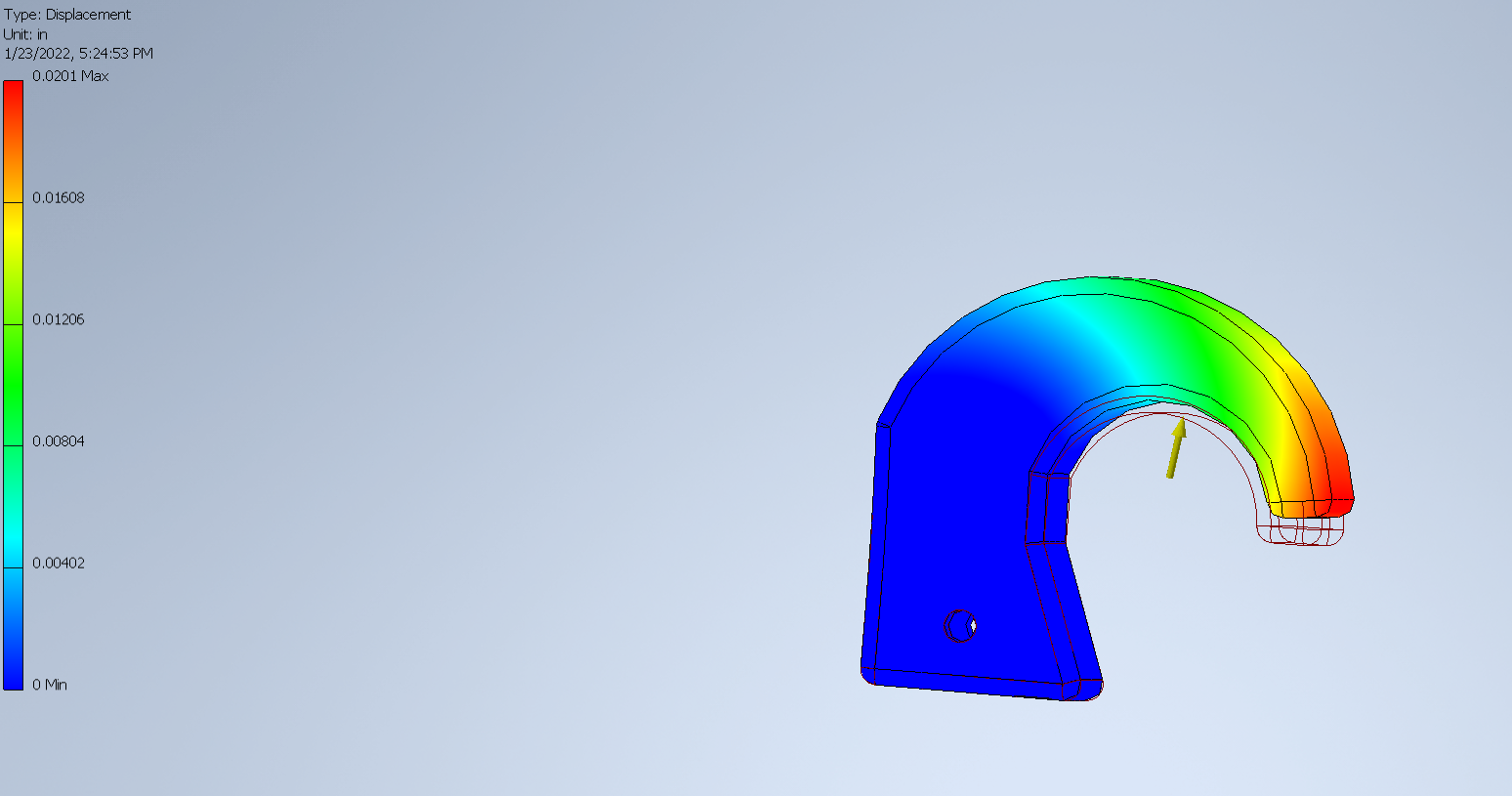

Today we created our static and moving hooks and conducted force studies on each. The studies are the pictures down below. All displacement test are scaled. LOOK AT THE NUMBERS NOT THE PICTURE!!!!!!!!!!!!!! We checked arm length to make sure they fit in the frame. We decided to go with a ratchet and pawl system in the drum. We are in the process of redesigning our drum mechanism in order to make it fit in the drive base. Marisa lost her sanity due to cad and 13 oranges. We began our hang recruitment effort as we need more people to do hang because we're all tired

1/27/2022

Today Nicole evaluated different constant force spring mounting brackets. Marisa, Hailey, and Walter worked to finalize the winch assembly. We ran into some issues regarding how we are going to store and rotate our arms, so we need to talk to our mentors on Saturday.

1/29/2022

Today, we focused on our arms. Audrey looked at the different stages the arms have to go to to go through a sanity check on our arm lengths. Nadia designed a mount for our constant force springs. Nicole worked with Stoeckl on calculations and mounting of our double piston design to move the arm. Marisa and Alex worked on calculations and designing of different methods of making the arms snap together.

02/01/2022 - 02/12/2022

We have finalized our static and extending arm design and claimed the space on the robot for it. We decided that we will use a ratchet and pawl inside of our drum mechanism. We finished the design of our static and extending hooks and 3D printed prototypes of both. We discovered that our static hook need more material on it or it would slide off the bar. We are using both pistons and servos to traverse the bars. We added a lip onto our extending hook in order to more easily latch on to the bar. We also began to add our hang cad to the final robot assembly.