2025:Controls: Difference between revisions

| Line 69: | Line 69: | ||

*<span style="background-color: rgb(241, 196, 15);">While waiting for parts:</span><br> | *<span style="background-color: rgb(241, 196, 15);">While waiting for parts:</span><br> | ||

***<span style="background-color: rgb(248, 202, 198);" >Bits and Pieces:</span> | ***<span style="background-color: rgb(248, 202, 198);">Bits and Pieces:</span> | ||

*****Locknuts for PEM Studs | *****Locknuts for PEM Studs | ||

*****Drill holes in tubes to fish wires through<br> | *****Drill holes in tubes to fish wires through<br> | ||

*****Velcro controllers and their holders | *****Velcro controllers and their holders | ||

***<span style="background-color: rgb(248, 202, 198);" >Wiring/Wire based:</span> | *****Flash - Get plastic/lexan<br> | ||

*****Lens - Make lexan part | |||

***<span style="background-color: rgb(248, 202, 198);">Wiring/Wire based:</span> | |||

*****Fix and test broken broken switches | *****Fix and test broken broken switches | ||

*****Make Ardinuno Board | *****Make Ardinuno Board | ||

*****Secure RJ45 Jack with approite secureness | *****Secure RJ45 Jack with approite secureness | ||

***<span style="background-color: rgb(248, 202, 198);" > | *****Add Wires to LED buttons | ||

***<span style="background-color: rgb(248, 202, 198);">Magnets:</span> | |||

*****Find nuts | *****Find nuts | ||

*****Dremal to fir | *****Dremal to fir | ||

*****Lexan as a spacer??? | *****Lexan as a spacer??? | ||

*<span style="background-color: rgb(241, 196, 15);">While Test Fitting:</span> | *<span style="background-color: rgb(241, 196, 15);">While Test Fitting:</span> | ||

***<span style="background-color: rgb(248, 202, 198);" >Mounting:</span> | ***<span style="background-color: rgb(248, 202, 198);">Test Mounting:</span> | ||

****Knob, Magnets, Laptop + Controller Holders, Power/Ethernet | ****Knob, Magnets, Laptop + Controller Holders, Power/Ethernet, Buttons to Handles, Grip, Flash, Lens, Caps + Plugs | ||

***<span style="background-color: rgb(248, 202, 198);" >Bits and Pieces:</span> | ***<span style="background-color: rgb(248, 202, 198);">Bits and Pieces:</span> | ||

*****How many magnets will we be using??? | *****How many magnets will we be using??? | ||

*****Counter sink holes on top | *****Counter sink holes on top | ||

*<span style="background-color: rgb(241, 196, 15);"> | *<span style="background-color: rgb(241, 196, 15);">Painting (3D pieces are '''<span style="text-decoration: underline;" >NOT</span>''' being painted):</span> | ||

*** | ***<span style="background-color: rgb(248, 202, 198);" >Black:</span> | ||

*****Top | |||

*****Bottom | |||

***<span style="background-color: rgb(248, 202, 198);" >Red:</span> | |||

*****Laptop Holder<span style="background-color: rgb(241, 196, 15);"></span> | |||

*<span style="background-color: rgb(241, 196, 15);">Final Assembly:</span> | *<span style="background-color: rgb(241, 196, 15);">Final Assembly:</span> | ||

***Bottom Box: | ***<span style="background-color: rgb(248, 202, 198);" >Bottom Box:</span> | ||

*****Cord managment | *****Cord managment | ||

*****Velcro Laptop | *****Velcro Laptop | ||

*****Mount Caps + Plugs, Laptop + Controller Holders, Magnets | |||

***<span style="background-color: rgb(248, 202, 198);" >Top Box:</span> | |||

*****Mount Grip, Flash, Knob, Lens, Magnets | |||

***Top Box: | |||

*****Mount Grip, Flash, Knob, Lens | |||

== In Process == | == In Process == | ||

Revision as of 18:08, 28 January 2025

New Rules

- R907 *No AC inverters. OPERATOR CONSOLES must not contain AC inverters.

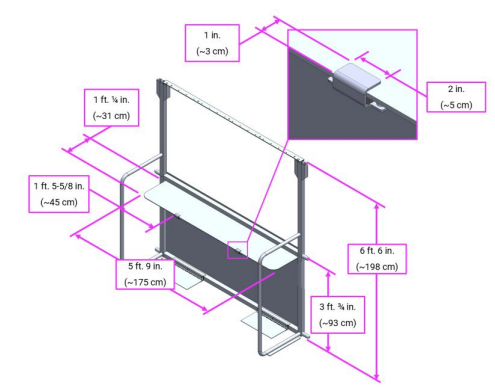

- The shelf also includes two clips to hold the shelf in place with a 1 in. (~25 mm) by 2 in. (~51 mm) thick tab that

DO NOT DELETE: Creating a Sheet Metal Part in OnShape for the L3Harris Model Shop

Overall Concept

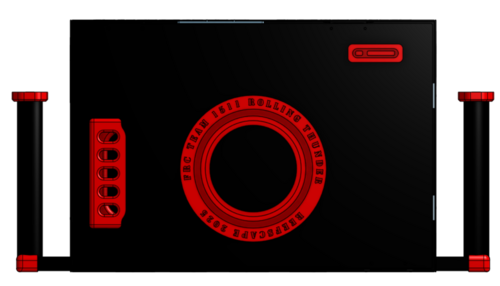

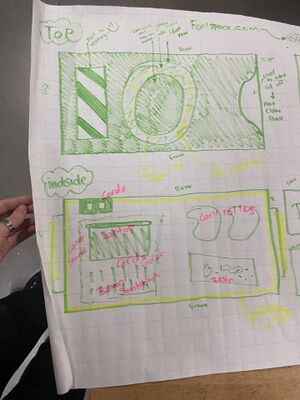

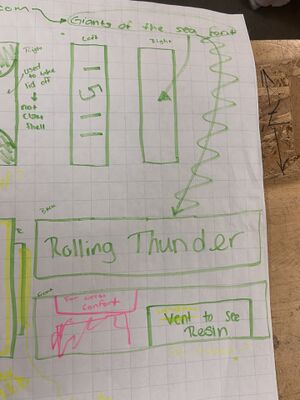

Dive Camera

Square Box (20" x 13.75"), One Handle on Each Side (8.5" Foam Grips ~1" round)

Pop Off Lid

Overall width: ~26"

Handles: 8.5" Foam Grips (Trim Down Later) with round 1" and 1.5" by 3/4" square stock

Lexan For Lens: 0.062 in Thick

Design Info

Paint Scheme:

- Bottom Box with Square stock metal - Black

- Top - Black

- End and top caps for handles - Black

- Laptop stand - Red

- Controller Holders - Red

- Lens - Red

Width considerations:

- Should be less than 29.680in in Length due to the NEW Clips... clam shell may not be ideal

- Try to get to box width to be 24" instead of initial 28" thought

Use 'Giants of the Sea Font' from fontspace.com for cut outs.

- Research options we did not use:

Controller Holder Starting Point

How to make grips: drill hole in top half of square stock and inset the round 1" tube and have L3Harris model shop weld them together, then put foam over the round tube.

Research options we did not use:

To-Do

(Sami) - Tools and Game Test: 100% BOTH

Not Started

- While waiting for parts:

- Bits and Pieces:

- Locknuts for PEM Studs

- Drill holes in tubes to fish wires through

- Velcro controllers and their holders

- Flash - Get plastic/lexan

- Lens - Make lexan part

- Wiring/Wire based:

- Fix and test broken broken switches

- Make Ardinuno Board

- Secure RJ45 Jack with approite secureness

- Add Wires to LED buttons

- Magnets:

- Find nuts

- Dremal to fir

- Lexan as a spacer???

- Bits and Pieces:

- While Test Fitting:

- Test Mounting:

- Knob, Magnets, Laptop + Controller Holders, Power/Ethernet, Buttons to Handles, Grip, Flash, Lens, Caps + Plugs

- Bits and Pieces:

- How many magnets will we be using???

- Counter sink holes on top

- Test Mounting:

- Painting (3D pieces are NOT being painted):

- Black:

- Top

- Bottom

- Red:

- Laptop Holder

- Black:

- Final Assembly:

- Bottom Box:

- Cord managment

- Velcro Laptop

- Mount Caps + Plugs, Laptop + Controller Holders, Magnets

- Top Box:

- Mount Grip, Flash, Knob, Lens, Magnets

- Bottom Box:

In Process

Completed

- Beginning Steps

- Confirmed for three Logitech controllers

- Collaborate and create ideas. Look at past Controls if needed.

- Take measures of computer and controllers being used. Look at 2024 Controls.

- CAD/Assembly (in CAD)

- Bottom Box

- Increase height for controllers: 4.25"

- Add notch for keyboard cutout

- Square cutouts for the handles

- PEM holes for laptop holder

- Notches for the AC power and Ethernet bracket

- PEM holes for controller holders

- fish font

- PEM Studs for magnets

- Figure out what's broken with the controller holder assembly

- Laptop Holder/Broken Switches (may just need to update drawings)

- ReCAD the laptop holder

- AC power and Ethernet bracket

- Controller holder(s)

- Words in Laptop holder: DIVE

- Get controller spacing fixed

- Finalize length: 20"

- Top (thicker material .093)

- Fill cut out in front (Bend Radius: 0.032 in; Bend Reduction: -0.145)

- Determine a method of keeping the top on the box - Will be doing the same method as Stronghold

- Find magnetic latches, get them on order. (Look in Design Info)

- Camera Lens (Holes for screws, Lexan)

- Camera grip/top opening (Holes for screws)

- Flash (Holes for screws)

- Holes for Camera Lens in top

- Knob (Holes for screws, clicky thing)

- Handles

- Cap for the top of the handles

- End cap for the bottom of the handles

- Fixed/ Added to the Handle Assembly

- Finalize design for handles

- Top Caps - create whole for button mounting

- Bottom Box

- Drawings

- Laptop Drawing

- Top Drawing (and Submit)

- Final Assembly

- Picked paint scheme

- Found Parts:

- AC receptacle, AC cable, RJ45 jack (NEEDS SOLDERED), broken switches, broken switch board, USB Hub, right angle USB adapters, Prototype Board, right angle Ethernet adapter

- Order Parts:

- extension cord with multiple outlets, nano ardiuno

- Reprint both handle Caps and Plugs in Red

- Solder RJ45 Jack

- Trim Wires on knob

- Replace the termanel ends on broken switch things

- Test broken switches

- Picked paint scheme

Meeting Minutes

1/4 (KICKOFF!) (Sat)

Attendees: Sami, Byers, Eric

Work Completed:

- Concept drawings started

1/5 (Sun)

Attendees: Sami, Byers, Eric

Meeting Minutes:

- Continued concept drawings

- Looked at NON-Wi-Fi controllers

- Created Wiki page

- Broke Wiki page

- FIXED Wiki page! :)

- Looked and took measures of the new clips on drivers station (see concept ideas)

- Added concepts

1/7 (Tue)

Attendees: Sami

Meeting Minutes:

1/8 (Wed)

Attendees: Sami

Meeting Minutes:

1/9 (Thu)

Attendees: Sami, Arlo, Colin, Eric, Byers

Meeting Minutes:

1/11 (Sat)

Attendees: Sami, Colin, Arlo, Oliver, Eric, Byers, Sam

Meeting Minutes:

1/12 (Sun)

Attendees: Sami, Byers

Meeting Minutes:

1/14 (Tue)

Attendees: Sami, Colin, Arlo, Byers, Eric, Charlie

Meeting Minutes:

1/15 (Wed)

Attendees: Sami, Eric, Byers

Meeting Minutes:

1/16 (Thu)

Attendees: Sami, Colin, Arlo

Meeting Minutes:

- Figure out what's broken with the controller holder assembly

- Cap for the top of the handles

- End cap for the bottom of the handles

- Increase height for controllers: 4.25"

- Top (thicker material .093)

- ReCAD the laptop holder

- Get controller spacing fixed (2.5" between controller and keep out zone)

- Finalize length: 23.75"

- AC power and Ethernet bracket

- Add notch for keyboard cutout

1/18 (Sat)

Attendees: Sami, Colin, Oliver, Byers

Meeting Minutes:

- End cap for the bottom of the handles

- Fixed/ Added to the Handle Assembly

- Square cutouts for the handles

- PEM holes for laptop holder

- Notches for the AC power and Ethernet bracket

- PEM holes for controller holders

- Found magnetic latches

- Laptop Holder/Broken Switches (may just need to update drawings)

- Controller holder(s)

- Determine a method of keeping the top on the box - Will be doing the same method as Stronghold

- Find magnetic latches, get them on order. (Look in Design Info)

- Find magnetic latches, get them on order. (Look in Design Info)

1/19 (Sun)

Attendees: Sami, Byers, Colin, Eric

Meeting Minutes:

- Bottom box

- fish fonts with lots of fishy water fish

- Words in Laptop holder: DIVE

- 🏆MILESTONE - HANDLES COMLETED🏆

- machined handle bar and pole in shop

- drawings, except laptop tray, are done

- 3d printed parts - perfecto

- finished magnet integration with other components

1/21 (Tue)

Attendees: Sami, Colin, Arlo, Eric, Byers

Meeting Minutes:

1/23 (Thu)

Attendees: Sami, Colin, Byers

Meeting Minutes:

1/25 (Sat)

Attendees: Sami, Arlo, Byers, Colin

Meeting Minutes:

1/26 (Sun)

Attendees: Sami, Byers

Meeting Minutes:

- Holes for Camera Lens in top

- Knob (Holes for screws, clicky thing)

- Top Drawing (and Submit)

- Re - printed things from yesterday

1/28 (Tue)

Attendees: Sami, Colin, Oliver, Charlie, Byers, Eric

Meeting Minutes:

- Solder RJ45 Jack

- Trim Wires on knob

- Replace the termanel ends on broken switch things

- Test broken switches

1/29 (Wed)

Attendees:

Meeting Minutes:

1/30 (Thu)

Attendees:

Meeting Minutes:

2/1 (Sat)

Attendees:

Meeting Minutes:

2/2 (Sun)

Attendees:

Meeting Minutes:

2/4 (Tue)

Attendees:

Meeting Minutes:

2/5 (Wed)

Attendees:

Meeting Minutes:

2/6 (Thu)

Attendees:

Meeting Minutes:

2/8 (Sat)

Attendees:

Meeting Minutes:

2/9 (Sun)

Attendees:

Meeting Minutes:

2/11 (Tue)

Attendees:

Meeting Minutes:

2/12 (Wed)

Attendees:

Meeting Minutes:

2/13 (Thu)

Attendees:

Meeting Minutes:

2/14 (Fri)

Attendees:

Meeting Minutes:

2/16 (Sat)

Attendees:

Meeting Minutes:

2/17 (Sun)

Attendees:

Meeting Minutes:

2/18 (Tue)

Attendees:

Meeting Minutes:

2/19 (Wed)

Attendees:

Meeting Minutes:

2/20 (Thu)

Attendees:

Meeting Minutes:

2/22 (Sat)

Attendees:

Meeting Minutes:

2/23 (Sun)

Attendees:

Meeting Minutes:

2/25 (Tue)

Attendees:

Meeting Minutes:

2/26 (Wed)

Attendees:

Meeting Minutes:

2/27 (Thu)

Attendees:

Meeting Minutes:

3/1 (Sat)

Attendees:

Meeting Minutes:

3/2 (Sun)

Attendees:

Meeting Minutes:

3/4 (Tue)

Attendees:

Meeting Minutes:

3/5 (Wed)

Attendees:

Meeting Minutes:

3/6 (Thu)

Attendees:

Meeting Minutes:

3/8 (Sat)

Attendees:

Meeting Minutes:

3/9 (Sun)

Attendees:

Meeting Minutes:

3/11 (Tue)

Attendees:

Meeting Minutes:

3/12 (Wed)

Attendees:

Meeting Minutes:

3/16 (Sun)

Attendees:

Meeting Minutes:

3/18 (Tue)

Attendees:

Meeting Minutes:

3/19 (Wed)

Attendees:

Meeting Minutes:

3/20 (Thu)

Attendees:

Meeting Minutes:

3/22 (Sat)

Attendees:

Meeting Minutes:

3/23 (Sun)

Attendees:

Meeting Minutes:

3/25 (Tue)

Attendees:

Meeting Minutes:

3/26 (Wed)

Attendees:

Meeting Minutes:

3/27 (Thu)

Attendees:

Meeting Minutes:

3/29 (Sat)

Attendees:

Meeting Minutes:

3/30 (Sun)

Attendees:

Meeting Minutes:

4/1 (Tue)

Attendees:

Meeting Minutes:

4/6 (Sun)

Attendees:

Meeting Minutes:

4/8 (Tue)

Attendees:

Meeting Minutes:

4/9 (Wed)

Attendees:

Meeting Minutes:

4/10 (Thu)

Attendees:

Meeting Minutes:

4/12 (Sat)

Attendees:

Meeting Minutes:

4/13 (Sun)

Attendees:

Meeting Minutes:

Controls Rules 2025

- 6.3.2 OPERATOR CONSOLES

DRIVE TEAMS set up their OPERATOR CONSOLE as soon as the DRIVE TEAM from the previous MATCH has

cleared the area. OPERATOR CONSOLES must be compliant with all relevant rules, specifically those in section

8.9 OPERATOR CONSOLE. The OPERATOR CONSOLE is plugged into the team’s assigned DRIVER STATION, as

indicated on the team sign. Any control devices worn or held by their HUMAN PLAYERS and/or DRIVERS during

the MATCH must be disconnected from or set on or beside the OPERATOR CONSOLE before the MATCH can

begin. A DRIVE TEAM obstructing or delaying OPERATOR CONSOLE setup is at risk of violating G301.

For the purposes of FIRST Robotics Competition, any device connected to the

OPERATOR CONSOLE is considered a control device because REFEREES are not

expected to differentiate between devices that can or cannot control the ROBOT. - R904 *OPERATOR CONSOLE physical requirements. The OPERATOR CONSOLE must not

- be longer than 5 ft. (~152 cm), B. be deeper than 1 ft. 2 in. (~35 cm) (excluding any items that are held or worn by the DRIVERS

during the MATCH),

C. extend more than 6 ft. 6 in. (~198 cm) above the floor, or

D. attach to the FIELD (except via the loop tape as described in section 5.6.1 DRIVER STATIONS).

There is a 4 ft. 6 in. (~137 cm) long by 2 in. (nominal) wide strip of hook-and-loop

tape (“loop” side) along the center of the DRIVER STATION support shelf that

should be used to secure the OPERATOR CONSOLE to the shelf. See section

5.6.1 DRIVER STATIONS for details.

Please note that while there is no hard weight limit, OPERATOR CONSOLES that

weigh more than 30 lbs. (~13 kg.) will invite extra scrutiny as they are likely to

present unsafe circumstances.

- R907 *No AC inverters. OPERATOR CONSOLES must not contain AC inverters

2025 Controller Map (Programming's Job)

Archives

- 2024:Controls

- 2023:Controls

- 2022:Controls

- 2020:Controls

- 2019:Controls

- 2018:Controls

- 2017:Controls

- 2016:Controls

- 2015:Electrical_Controls_Subteam

- 2014:Electrical_Controls_Subteam

- 2013:Electrical_Controls_Subteam

- 2012:Electrical_Controls

- 2011:Electrical_Controls

- 2010:Electrical_Controls

- 2009:Electrical_Controls