2017:Controls

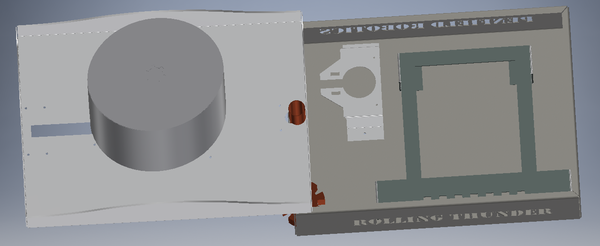

Overall concept

Rectangular base large enough to hold the any of the current laptops that we have (approx 19.25" W x 13.75" D)

Top/lid will resemble a top hat.The sides will be curved to look like the brim. Painting will help define it better.

The hat will hold the XBOX controllers. A lid will be held on with magentics (drivers remove lid, pull out controllers).

Top will swing out on a pivot (1" copper pipe). Pivot will be on the left side, centered front-to-back. Top will be latched on the right side. There will be a 'kickstand' that swings down to support the top when it is swung open (1/2" copper pipe). The 'kickstand' will be held up by a magnet.

Controller cables will come up out of the pivot, then go into the hat.

Ethernet plug will be at the top of the pivot.

Power will come out of the base via retractable cord (from an iron).

To do

Need to figure a better way to route the cables (things are too tight for cord reel cord to work well; maybe get right angle for USB & ether) [USB swivel adaptors are on order]Clean-up wires (on top, may need no work if we just velcro were it is now, and within base)- Design divider for the inside of hat

- Add guitar straps (drill ourselves)

- Add camo fabric on top hat [Janet S is making this]

Whistle?Modify kickstand bracket (may not need, but would need to do something with the studs; probably leave until after bag day)Interferes with hat - add to base so holes can move backMight need to make it bigger to hold the magnet.

Completed

Eric: Verify cables are ok as top swings open/close (needs to survive entire season).Replace end on ethernet (PC side); Jeff said he would have Cathrine to do it, so it might be doneAdd labels for broken switches (use White on clear, which we already have; Jeff said their names should be on the wiki)Create images for the controllers, to put in dashboard (placeholders already in source control)Install controllersTest LEDs and borken switch USBRe-install top half of latches after rim painting is complete on that end.Finish painting brim[this is complete enough for now; do more after bag day - need to fix overspray]Determine if we are going to fabricate the top hat. [we are fabricating]Create drawing for the top oval of the top hat. We will need two of these, one for the bottom and one for the top. [sent 1/22/17]Create drawing for the door of the top hat. [sent 1/22/17]Move pivot point inside the box, need to determine the correct pipe [has been moved inside; using 1" copper pipe from Home Depot]Find USB joystick part. [in shopping list; recieved]Find PWB for driving the LEDs [in shopping list; recieved]Determine if we need a (gutair) strap, if so add holes for it. [will do strap; hand drill holes later; take from last year's controls]Order LEDs [we have enough already. not enough for robot, so the robot team can order what the robot will need]Find and order round USB hub [in shopping list]<s></s>pick magnet to hold up kick standmake bracket to hold magnet (already have pressed in studs in top)Laptop holder heightcord reel highest, so go by thatput laptop power under itput lights PWB under itput broken switch PWB under it

Base depthlaptop holder + velcro + laptop + 1/4" for safety

Top pivotput cap on bottom of pipeuse U clamps to restrain to side of bottom: 1st just above the end cap; 2nd near top edgeT on top of pipe, with T resting on top's bottom surfacehow to attach to top? solder flat stock to T and bolt to top (will need pressed studs for this in the top). Bushing? (if so, need to move pipe further from side) [use T, it will rest on top, maybe clamp to top]ethernet goes on top

Topneed pressed in studs to hold hat's lower rimput in 'recess' for bevel of Tpressed in studs for strap that holds down Tmake hole through top the diameter of a 1" Tfinalize brim curvesfinalize pivot attachment (see Top Pivot)

Bottompressed in studs for laptop holderpressed in studs for PWBspressed in studs for cord reel bracketdouble-check letter height, now that we made the side tallercutout for gearcutout for power cord and release [no longer needed]Cut lettering into sides of controls.

Cord reelCAD bracket to hold it [started]slots for 'hooks' to go intoholes for bolts at bottom (currently has zip ties in them to keep cord together)maybe shave off the 'feet' on band sawmaybe integrate into laptop holder [will be its own bracket]needs to be near a side so cord can exit base and release be pressed [cord will be pulled up through after the top is opened]

Top Latch [went with 1/2" copper pipe held with straps; magnetic to hold it up]design similar to 'gate cane bolt' (<a href="http://www.homedepot.com/p/Everbilt-12-in-Black-Gate-Cane-Bolt-15464/202042236">http://www.homedepot.com/p/Everbilt-12-in-Black-Gate-Cane-Bolt-15464/202042236</a>)one nub at height to support top when openanother nub to lock latch when top is closedneed bracket for side of base, to 2nd latch nubhole and offset slot in top to be able to pull up latch (latch needs to clear top so top can swing open)Other ideas: latches on end to hold top, and a 'kick stand' to support the top (held up by magnet) - could be copper, aluminum/steel in a variety of shapes, wood dowel that looks like a rope, etc.)<s></s>

Look at Bob's steampunk stuff for inspiration.<s></s>design 'gear' cover for USB hub (3D printing this) [we have something, it was sent to Eric]design 'corner' gear (3D printing this) [we have them back; 2 actually]pick latches that will go on the endsDesign something to hold/retain the Ethernet connector we decide to use.Design gear train (3D printing these, drill holes ourselves, need to go around handle; might not even have space)[we do not have space]Put on shopping listEther net port (need to pick one or use what we have; investigate after we have cooper pipe)Order/FindHome Depot1 - 1" copper T1 - 1" copper end cap3 - 1" copper pipe straps1 - 6" length of 1" copper pipe1 - 1/2" copper T3 - 1/2" copper pipe straps2 brackets for handle <a href="http://www.homedepot.com/p/Cramik-Enterprises-1-2-in-Copper-Plated-Van-Hanger-3002/100168841">[brackets</a>]1 - 3/4"+ NM twin-screw clamp (for cables into hat) [unless Eric finds one]latches for topPass through Ethernet jack1 - 6" length of 1/2" copper pipe (should might already have)[we have this]Magnet to hold up 'kick stand'find thin metal for hat (roll of flashing: Debbie Supply or Home Depot (<a href="http://www.homedepot.com/p/Amerimax-Home-Products-10-in-x-10-ft-Mill-Finish-Aluminum-Roll-Valley-68310/100054269">http://www.homedepot.com/p/Amerimax-Home-Products-10-in-x-10-ft-Mill-Finish-Aluminum-Roll-Valley-68310/100054269</a>))[do not need, Mark brought in some]magnet for 'kickstand' (still need to pick one)

*** ERIC LOOK HERE ***perf board for PWBs (3" x 9")1 - 3/4"+ NM twin-screw clamp (for cables into hat)12 - #4 and #8 stand offs (to told up perf board from base; light PWB to perf; joystick PWB to perf[we have some in MPT bin 10C]16 - spade connectors for broken switches[we have these]USB extension cable for PWB4 - 5 pin headers[we have these]1 - 1000uf 50V capacitor1 - 52ohm resistor1 - 3pin connector for end of LEDs to perf board[we have this]

Pre-assemblyslot in 1" copper pipe to run cablesCord Reel BracketGrind out interference that is marked in green on one of the bracketsTest fit to cord reel including finding bolts to hold the cord reelPaint

Laptop BracketTest fit in baseTest fit switchesPaint

BaseFind/install post for the gear in corner, test fit gearDrill holes for pipe mounting straps (they might interfere with numbering)Drill holes for latches and test fitPaint

TopDetermine how we are going to deal with the interference issue between the kickstand and hat: Can either notch hat, slide hat over, or rotate hat 90°.Drill holes for latches and test fitInstall and test kickstand.Install and test main pipe.Paint[spary paint is complete; brim still being worked on]

Post-assemblyGet handle brackets and straight piece of pipeLED InstallHandle. 2 brackets <a href="http://www.homedepot.com/p/Cramik-Enterprises-1-2-in-Copper-Plated-Van-Hanger-3002/100168841">[brackets</a>] plus straight pipeNeed a 'stop' to keep people from opening the controls the wrong way; otherwise the cables will be cut)Add female A/C power plug to cord reel (end and some cord is in the controls).Place USB hub (velcro in place)Do the Dave B test on the broken switch spade connectors (make sure connections are solid)Pick laptop and install power supply (Jeff says to use last year's Thinkpad ffor now)Need to order a different right angle power; the one we got was for a Dell)[one is on the shopping list]

Horipad Driver Install

Get Driver

Microsoft instructions: http://support.xbox.com/en-US/xbox-on-windows/accessories/connect-xbox-one-controller-to-pc

Follow Windows 7 steps under: Download and install Xbox One Controller driver

You must use Internet Explorer

Get the one called "Microsoft - Other hardware - Microsoft Xbox One Controller" that is for AMD64 (i.e. 64-bit).

If 7-zip is on the PC, use that to expand the contents of the .CAB file.

Install - First Controller on the PC

Plug in control

It will not find one anywhere, so you can tell open the New Hardware wizard and click 'Skip Searching Windows Update'; otherwise you will be waiting forever.

Open Windows' Device Manager; find the Horipad controller; right-click and select 'Update Driver'; then browse to the folder where you unzipped the .CAB file.

It will take a while to install (this is another point where you can tell it to 'Skip Searching Windows Update'.

Once the Gamepad is done, it will then search for a HID driver. Not sure if 'Skip' can be used in this case, so let it finish on its own.

NOTE: if driver fails with error 37, then the problem is that the wdfcoinstaller01011.dll is not in the C:\windows\system32. the installer copies it to c:\windows\system32\driver instead. so copy wdfcoinstaller01011.dll from c:\windows\system32\driver to c:\windows\system32

Install - Second Controller on the PC

Plug in control

Since you have the driver already installed, you can open the New Hardware wizard and click 'Skip Searching Windows Update' for the gamepad.

It will then install the HID portion, again you can 'Skip Searching Windows Update'.

PSoC Install (for lights)

PSoC Creator IDE

Download latest "PSoC Creator" from Cypress (http://www.cypress.com/products/psoc-creator-integrated-design-environment-ide) and install it (use Typical install; at end run Updater and maek sure you have the latest stuff)

For user name and password, you can use: mailme@mailinator.com mailme123

Toolkits and Board Driver Install

Get controls2016 from SVN

Run: vcredist_x86.exe

Run: USBSerialSDKSetup.exe (do Typical install; at end run Updater and maek sure you have the latest stuff)

Run: CY8CKIT04942xxSetupOnlyPackage_revSA.exe ()do Typical install; at end run Updater and maek sure you have the latest stuff)

While you press and hold the SW1 Prog button on the cypress board, plug in the USB cable to the PC (it will take a while for it to install 5 drivers).

Build/Program

Open PSoC Creator (Start -> Programs -> Cypress -> PSoC Creator -> PSoC Creator)

Open project: File -> Open -> Project/Workspace; then browse to FRC2016/controls2016/SCB_Bootloader/SCB_Bootloader.cywrk)

Build project: Build -> Build All Projects

While you press and hold the SW1 Prog button on the cypress board, plug in the USB cable to the PC

Download Boot Loader:

- open programmer: Tools -> Bootloader Host

- set 'File' to C:\Users\Robotics\Desktop\FRC2016\controls2016\SCB_Bootloader\Bootloadable Blinking LED.cydsn\CortexM0\ARM_GCC_493\Debug\Bootloadable Blinking LED.cyacd

- select the com port for the cypress board

- set Baud to 115200; Data Bits 8; Stop Bits 1; Parity None

- download program: Actions -> Program

Zero Delay USB Joystick Encoder

Meeting Minutes

1/14

Attendees: Eric, Mark, Aidan, Jeff, Brandon, Vincent, Josh

Work Completed: Initial brainstorming of controls design. Came up with a good concept based on a rotating lid with a top hat mounted to it.

1/15

Attendees: Mark

Work Completed:

1/17

Attendees: Mark

Work Completed:

1/18

Attendees: Eric, Aidan

Work Completed: Started CAD design of controls.

1/19

Attendees: Eric, Mark, Aidan, Jeff

Work Completed: Completed a bit more of the CAD design. Eric and Mark came up with a complete list of To Do items that have been updated on the Wiki which should be the focus of Saturday.

1/21

Attendees: Eric, Mark, Alex, Zach, Aidan

Work Completed: Updated the Wiki. Decided we are fabricating the hat. Order a bunch of parts. Determined overall outer dimesnsions of the control box. Andrew prefers first choice XBOX controller.

1/22

Attendees: Mark, Aidan

Work Completed: Met with drivers to determine what the controller buttons will be. Casey wants the Horipad (i.e. last year's control). Updated top hat pieces (1" bigger to look good with rest of stuff). Create drawings & files for had rim and lid. Finished hat rim and lid and sent it to Harris. CADed the base of the Iron.

Received: iron [on controls shelf]

1/24

Attendees: Mark, Aidan, Alex

Work Completed: Re-did hat lid drawings. Put new top into assembly and fixed constraint. Updated light cut outs in laptop holder. Updated CAD for power supply (Dell is bigger); Added CAD for Lights PWB

Received: power adaptor; usb board [they are in the blue controls coffee can]

1/25

Attendees: Mark

Work Completed: Removed retractable cord from iron. Re-did todo list. Filled in overall concept section.

1/26

Attendees: Eric, Zach, Aidan

Work Completed: Cleaned up the cord model a bit. Added a cap to the copper pipe in the model. Spent more time thinking about how the hinge is (not) going to work. We received the LED controller and switches too, they are in the blue bucket.

1/28

Attendees: Eric, Mark, Zach, Aidan, Alex

Work Completed: Thinned down the cord reel. Decided on placement of cord reel. Finalized laptop holder. Finalized base. Finalized pivot design. Top is complete, except for changes needed for support. Come up with ides for top latch/support.

1/29

Attendees: Mark, Aidan, Jeff, Andrew

Work Completed: Kickstand design completed and top modified. Cord reel bracket completed and bottom modified. Created drawings for: top, bottom, laptop holder, cord reel.

1/31

Attendees: Jeff, Alex, Mark, Zach, Eric

Work Completed: re-did laptop drawing, put picture of controls in overview section, found some parts we need, cleaned-up needed parts list

2/1

Attendees: Mark, Zach

Work Completed: Bent hat rim pieces. Attached flashing to top rim of top hat, using foam rivets that had there shank cut down.

2/2

Attendees: Eric, 1/8 Aidan

Work Completed: Fixed cord reel bracket drawing. Worked on the magnetic bracket a bit.

2/4

Attendees: Mark, Zach

Work Completed: Top hat riveted and hot glued rivets to prevent cables from getting cut. Spade connector put on broken switch connectors. Some more work on the 3D model for the USB hub gear. Dashboard all prep'd for 2017 work.

2/5

Attendees: Mark

Work Completed: tried to see if USB PWD could do analog; it could not.

2/7

Attendees: Zach, Mark, Alex

Work Completed: Finished magnet bracket, more work on hub gear

2/8

Attendees: Zach, Mark

Work Completed: Finished 3D model for usb hub gear

2/9

Attendees: Eric

Work Completed: Test fitted some of the metalwork. Found some issues. Created a list of the stuff that we need to do next.

2/11

Attendees: Eric, Zach, Mark

Work Completed: Put on handle, Fixed cord holder, Drilled and fitted hat onto top, Finished stand, Finished rotation pipe and mounted it to base. Disassembled and black spray paint completed.

2/12

Attendees: Mark, Zach

Work Completed: Completed spray painting. Re-assembled everything. LEDs installed (had change perf board placement so LEDs did not interfere with 1" pipe pivot and gear). Broken switches wired. Ethernet mount figured out and mounted. Wires run through 1" pipe. Kate & Ally were working on painting brim.

2/13

Attendees: Mark, Kate

Work Completed: Re-attached latch tops. Tested and fixed broken switches. Hot glued cables coming out of 1" pipe (looks like top was spun open the wrong way). Had to use USB extension cable from last years controls. Dressed wires in base (ether, broken pwb, lights pwb). Verified lights work. Gather parts for A/C power. Installed controllers.

2/14

Attendees: Zach, Alex, Aidan

Work Completed: ZAK took game test and looked for things.

2/15

Attendees: Mark

Work Completed: Added screws to help prevent top from swinging the wrong way. Wired A/C and laptop power. Verified spade connections. Order right angle for Thinkpad power.

2/16

Attendees: Zach, Alex

Work Completed: Labeled broken switchs, updated controller maps(Images in imgae folder for dashboard)

2/17

Attendees: Mark

Work Completed: Added 'edit' support to dashboard; put in images from Austin/Thompson

2/18

Attendees: Mark, Alex

Work Completed: Created 'cover' for laptop; dashboard

2/19

Attendees: Mark, Zach

Work Completed: Tested divider idea (for inside hat) with cardboard

2/21

Attendees: Mark

Work Completed: Looked into handle extenstion ideas

2/22

Attendees: Mark

Work Completed: Extended handle. Put clear coat on base. Moved in gear so controls can 'stand' on the end

2/25

Attendees: Mark, Kate, Alex

Work Completed: Added more light patterns. Creating pipe & smoke for the magnet bracket. Talked with Julia about top ideas.

2/26

Attendees: Eric, Alex

Work Completed: Finished smokestack magnetic braket.