2018:Cube Mechanism

Cube Subteam

Leads: Tom C, Andrew F, Matt D

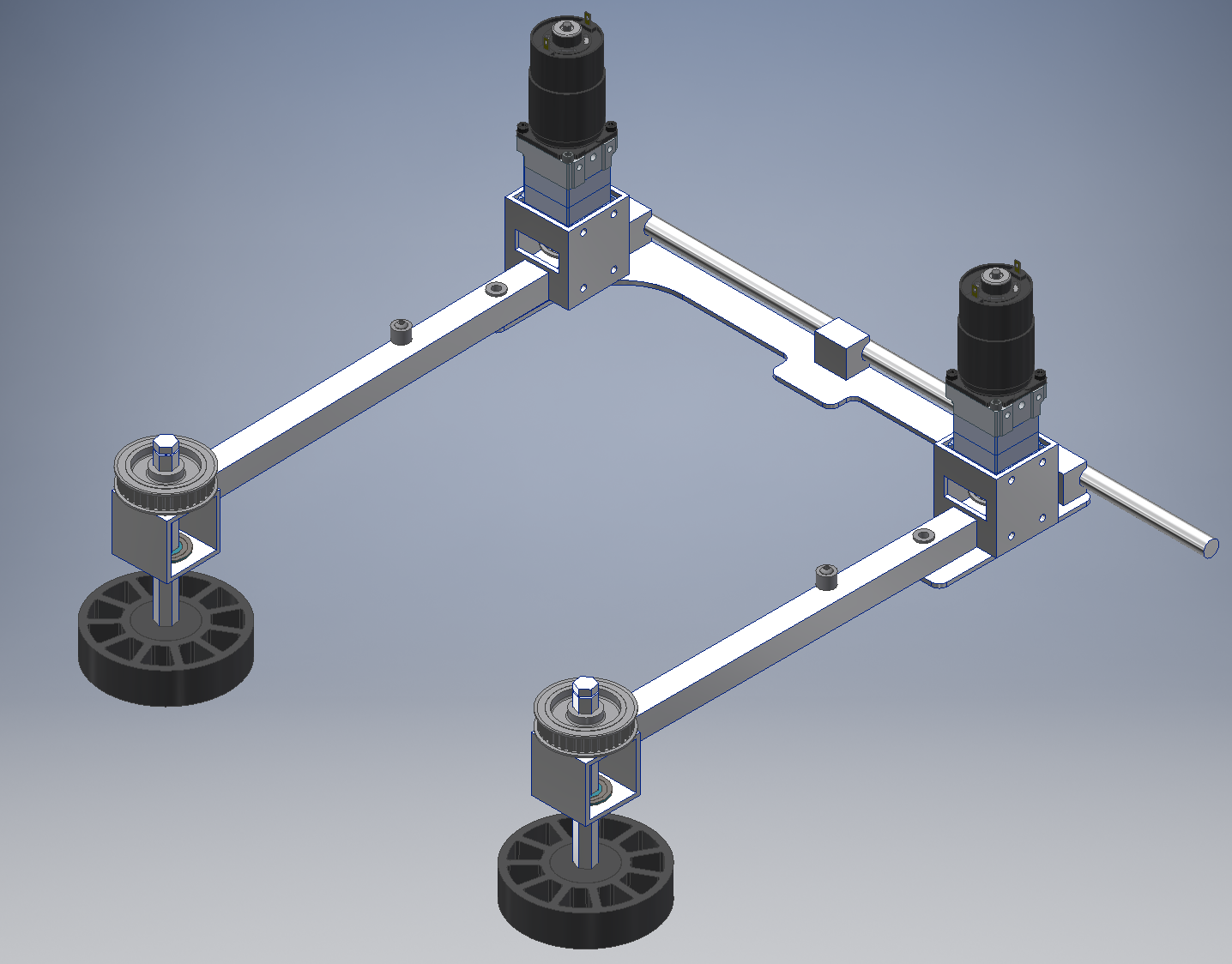

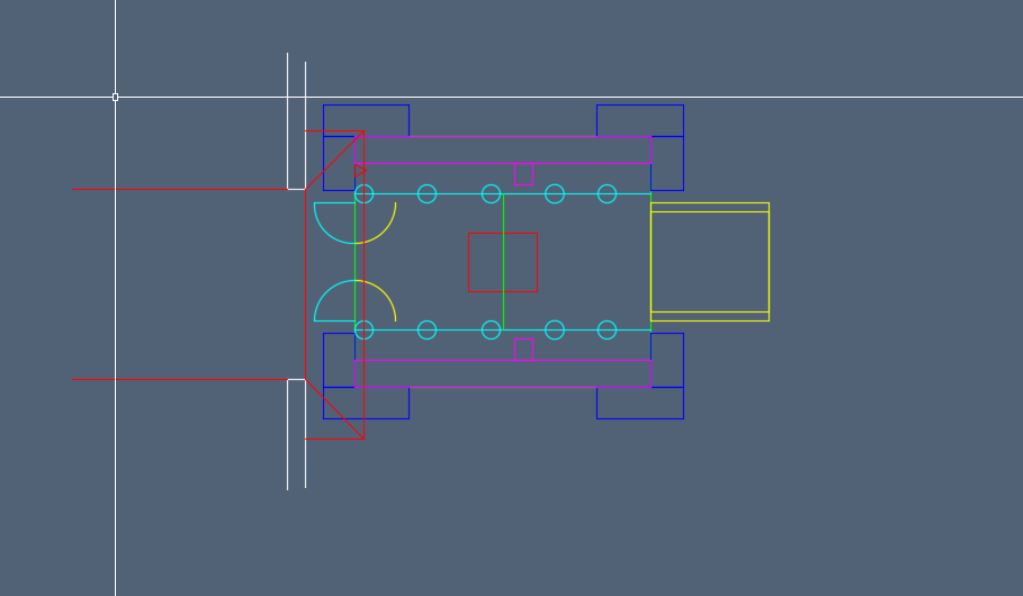

Current Intake

- Weight: 6.292 lb + fasteners

- 2 775pros geared with 5:1 and 3:1 for 15:1 reduction

Prototype Intake

- Side rollers with 1 blue compliance wheel on each side as close to the ground as possible.

- Rollers are on arms that can pivot outwards and are tensioned with surgical tubing attached to the frame.

- Rollers are belted to motors mounted on the arms.

- 2 775pros geared 30:1.

- Changed to MiniCIMs geared 8:1.

- 10.5" long arms.

- Intake must grab the cube in a way that when it flips over to the other side the cube is in the right position for the exchange.

- Capable of grabbing any cube it touches.

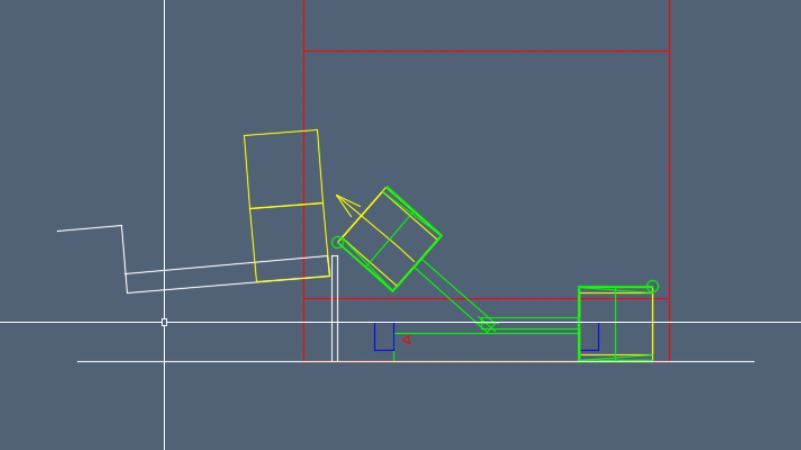

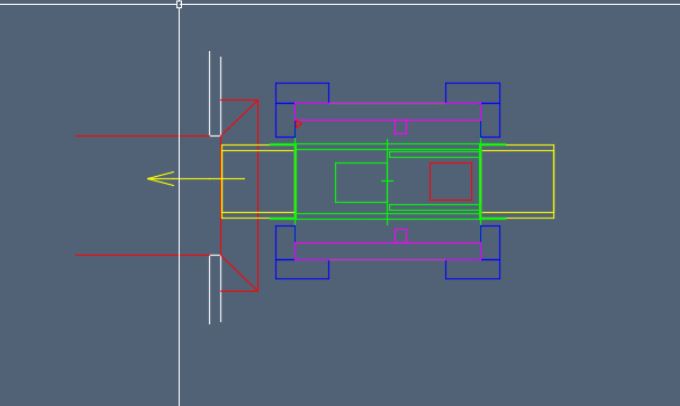

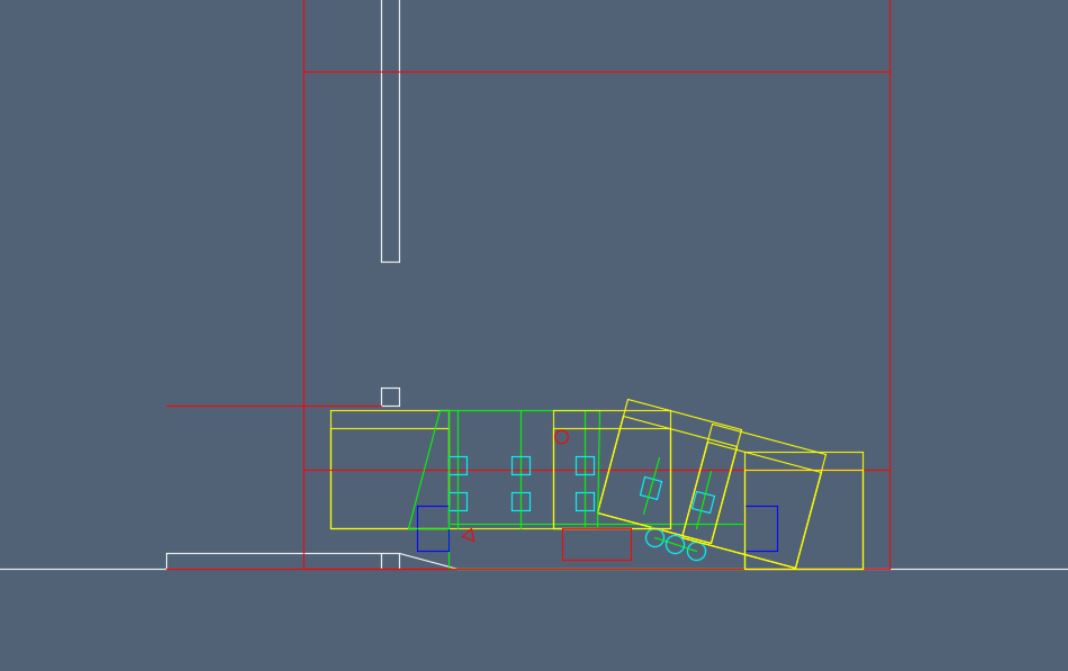

This drawing depicts how the intake would fold into the drive train.

- Note: this design is not being used, the intake now pivots up instead.

Current Cube Transport

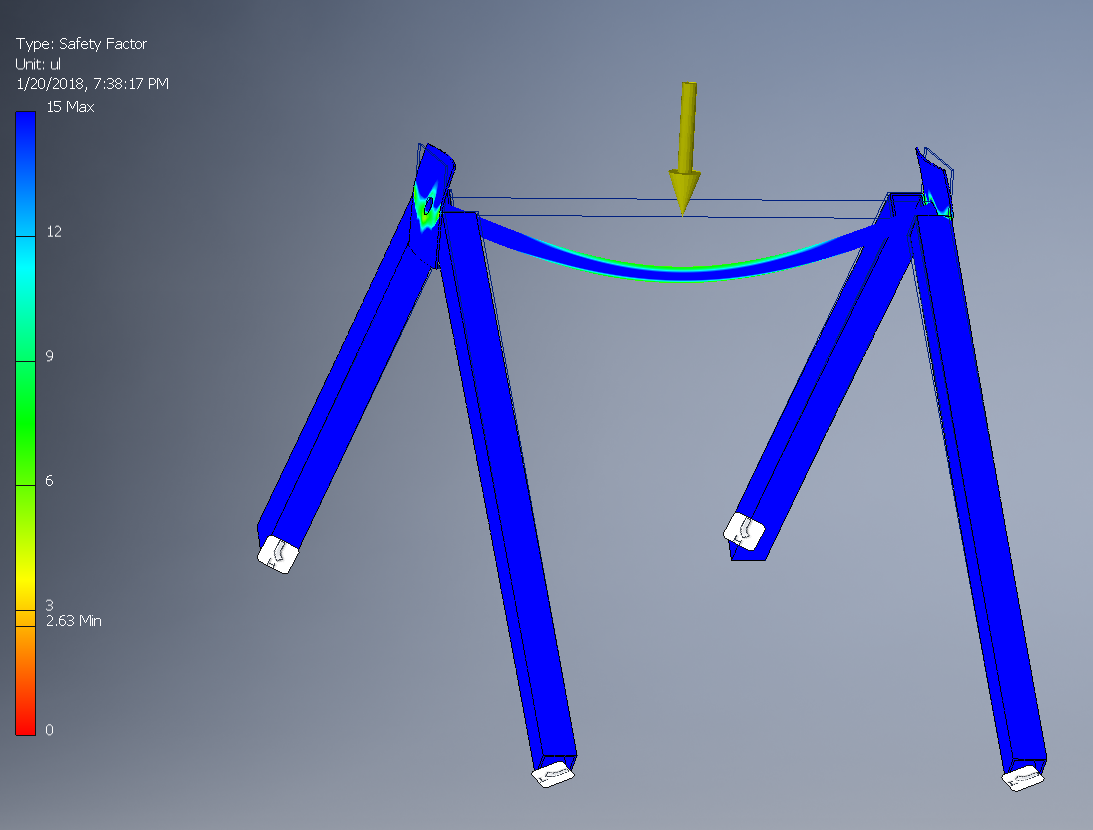

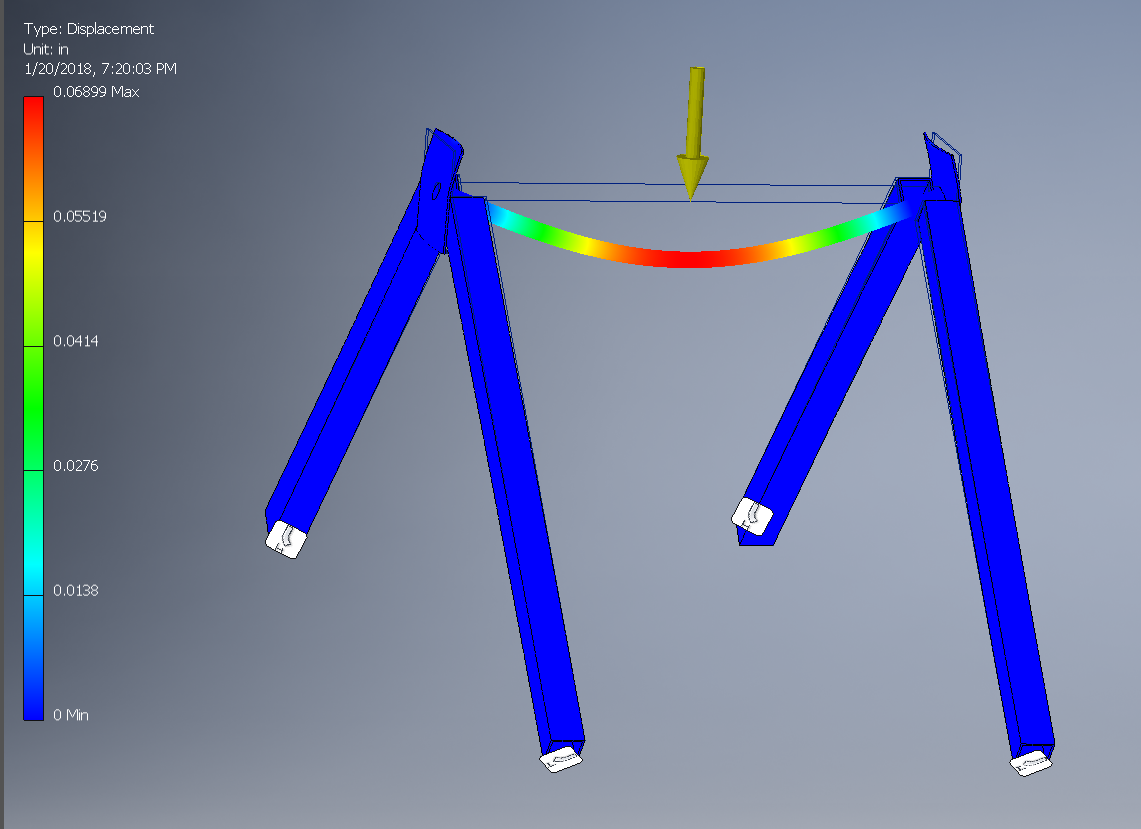

We have decided on an arm design. The plan is to be able to rotate 180+ degrees for easy Power Cube Zone to Exchange times.

Calculations have been done for the arm and the next task will be to figure out gearing and sprocket sizes to finalize the numbers.

Meeting Notes

1/7 - Sunday:

- Intake:

- Started work on roller intake prototype

1/9 - Tuesday

- Intake:

- Put grooves in 4" compliance wheels to increase friction

- Arm tensioning moved to points on frame so they move independently

1/10 - Wednesday

- Intake:

- Belted motors to frame, now driving the rollers with drills will not affect the movement of arms

- Arm pivot point moved so they are 10.5" long, which makes sure we do not pick up multiple cubes at once.

1/11 - Thursday

- Intake

- 6 wheels on each roller. Now that wheels are contacting almost everywhere on the cube, the intake is more consistent and cube doesn't tilt as much on entry.

- Taped a lexan sheet to carpet to simulate something on the bottom of the intake. This alleviated some of the friction from the carpet once the cube entered the intake

- Almost finished mounting motors to arms so we don't have to drive it with drills.

- Arms are mounted to a C-channel on a hinge so we can start to look at what happens after intaking the cube (like lifting it up).

- Likely going to switch to 2" compliance wheels due to geometry inside the robot with the ramp.

1/13 - Saturday

- Intake:

- General robot design decision: intake will be separate from transport mechanism

- Motors mounted

- Added a roller to each arm that touches the ground instead of the wheel shaft.

- After playing with different amounts of wheels in different locations on the shaft, we determined that one wheel at the bottom is best because of how much lighter it is than having more wheels. This means it spins up quicker and also allows the arm to be more springy.

- We realized that lifting the cubes straight up while it touches the wheels is near impossible so that will need to be figured out.

- Could be as simple as actuating the arms outwards when we want to lift up the cube.

- We also began prototyping a roller, which consists of rubber stretched over a plastic tube. This is extremely light and it initially seems to have a ton more grip than any wheels.

- Matt D. is probably going to use these in a prototype of the arm/claw.

1/14 - Sunday

- Intake:

- Changed 775pros to MiniCIMs with 4:1 gearboxes for a total ratio of 8:1

- This worked much better than the 775pros.

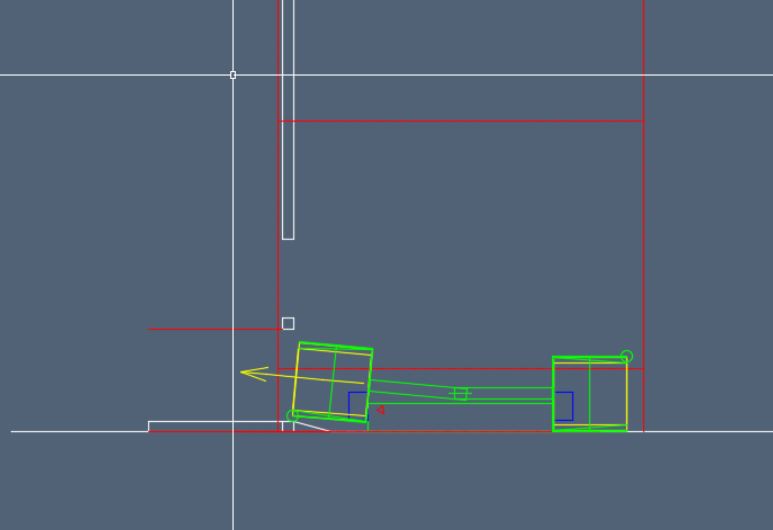

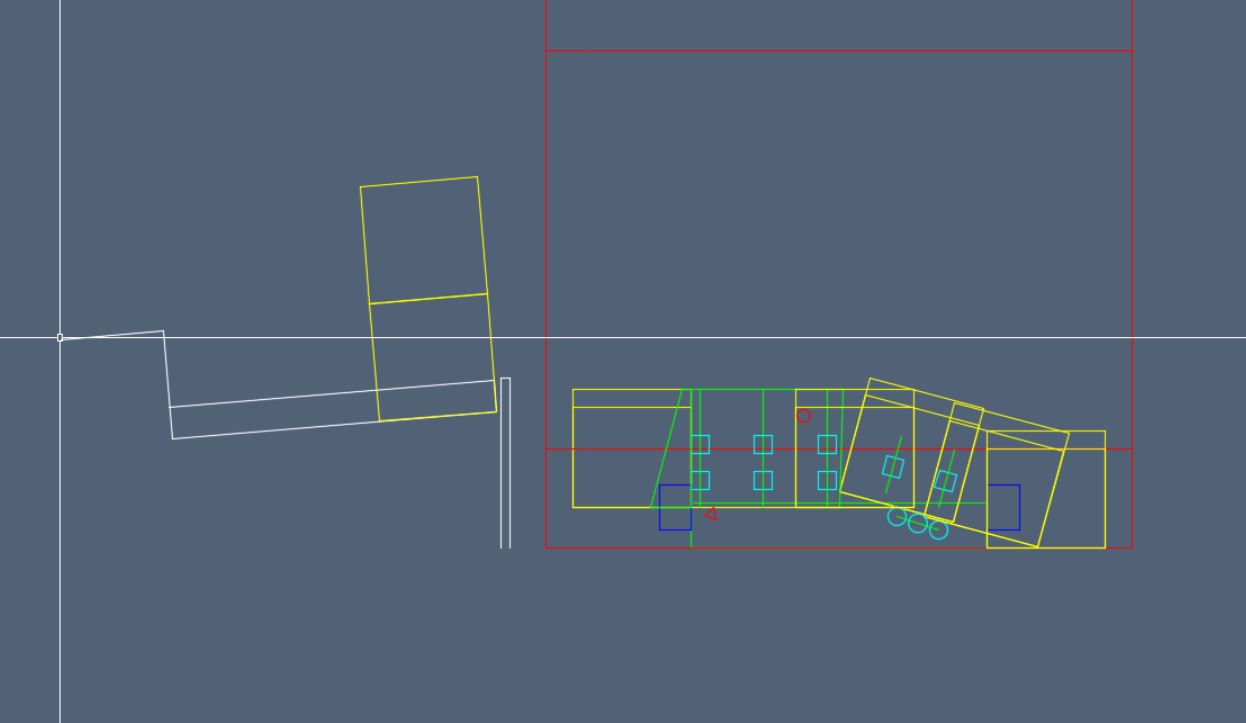

- Calvin and Tom worked on 2D CAD sketches to show the geometry of the intake arms folding in and out.

1/16 - Tuesday

- Intake:

- Swapped pulleys on MiniCIMs for a total ratio of 2:1

- The wheels slipped a lot on the cube and this did not work as well as the 8:1 ratio.

1/20 - Saturday

- Intake

- Estimated weight: 6.292 lb (not including fasteners)

- Put parts on shopping list:

- Motors and gearboxes

- Bearings/Bushings

- Aluminum stock

Historical Design Documentation

Transport

Time Trials

On 1/10/2018 time trials were conducted using past years' robots to determine how much driver control affected timings for picking up a CUBE and getting it to the EXCHANGE. Picking up, driving backwards and delivering the CUBE to the EXCHANGE was compared to picking up a CUBE, turning 180 degrees, abd delivering the CUBE to the EXCHANGE.

| 2016 | 2017 | AVERAGE | 16" FP Extensions | |

| 180 Degree Turn | 53 | 47 | 50 | 42 |

| Back & Forth | 35 | 33 | 34 | 27 |