2020:Power Cell Intake

From 1511Wookiee

Jump to navigationJump to search

Team Leads: Matt D. & Kyle B.

Design Details:

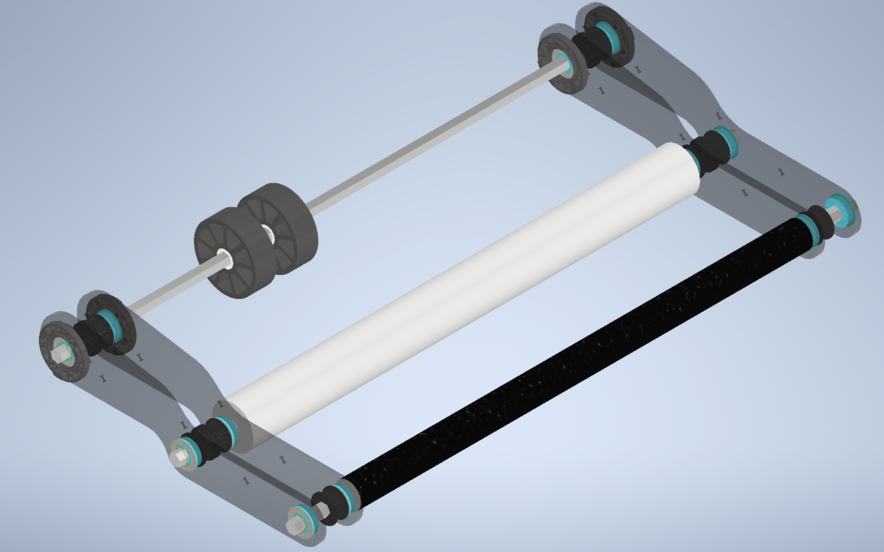

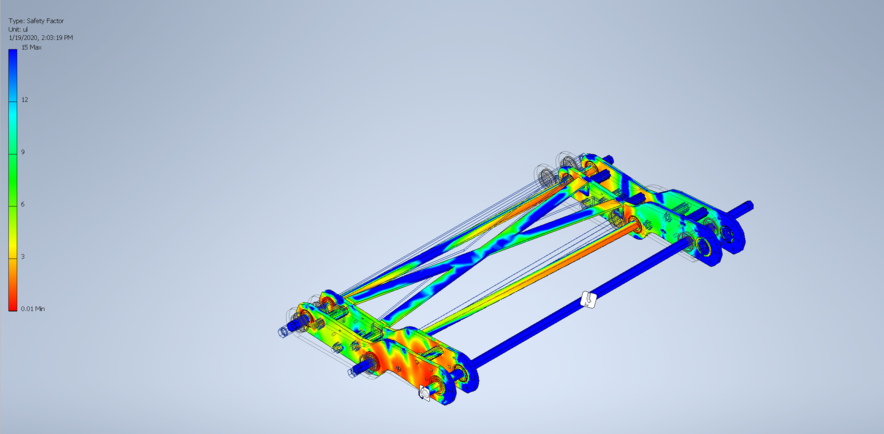

- Two roller system. One "Hot dog roller" which is a polycarb tube covered in a thin rubber material that grabs the balls and pulls them into the second roller, full of left, 3D Printed mecanum wheels that redirect the ball into a cut in the frame where they are indexed by a beam break sensor that counts the balls as the enter the robot. The handoff from the intake to the helix is two compliance wheels on the same axle as the pivot that pull the balls into the helix. The rollers are powered by a NEO 550 @ a 16:1 gear ratio and the pivot is powered by a NEO 550 motor @ a 100:1 gear ratio.

Prototyping 1/5/2020-1/11/2020

Overview: Based on initial team brainstorming and sketching, as well as theinformation from Strategy Subteam, we determined to prototype:

- An over-the-bumper intake:

- A thru-the-bumper intake

This decision is critical as it affects Drive Base!

- Test using various componenets touching the balls:

- Test brushes

- Test wheels

- Test "hot dog roll" - a material wrapped around a rod that grips the game piece well and will snag it.

- Test mecanum wheels to direct the balls into the robot in a manner that can be counted or indexed.

- Combinations

Observations: We observed the following over the course of prototyping:

- It is not difficult to get the balls to go over the bumper.

Decisions:

- Intake will pivot out of the front of the robot

- Intake will be full width (relatively) of the robot

- Larry, Tom C., and Kyle discussed the pros and cons of having the balls go over or through the bumpers. Pros for a design that takes the balls over the bumpers included a simpler design that has more integrity. Pros for a drive base frame cut for the balls include a funnel that would only allow for one ball to enter the robot at a time, vastly decreasing the chance that we intake more balls than we want. Drive base cut also makes sensor placement to count the balls better. After the discussion, we decided on making a cut in the drive base frame for the intake, and the cut will be 8-9 inches wide.

Working towards a design that will extend the intake mechanism out of the frame perimeter and put it back in. Four bar design similar to 971's 2019 intake.That design would put us over the frame when the intake is stored.- Intake deploy is currently motor-driven and rotates the intake mechanism 90 degrees around a pivot point just above the frame.

- Decided on the foam roller + mecanum redirect bar design.

- Prototype is complete! Mecanums redirect the ball very well, experimented with wheel spacing, axle height from ground, mecanum axle distance from the frame perimeter, etc.

Need to do:

DECIDE OVER-THE-BUMPER OR THRU-THE-BUMPER!If THRU, determine the size of opening needed in the Drive Base.

Determine how the intake will interface with the Storage- Roller bar on top of the balls when the enter the robot from the intake, passive roller below said roller bar. Pushes balls into the helix.

- Test the interface

Test mecanum wheels (on order)Out of stock,both the 2 inch omnis and the 2 inch mecanums are on order. Omnis from AndyMark, Mecanums from WCP (on backorder, should ship this week)

Test plastic mecanum wheels (being assembled)- 1/8/20: 4/8 have been assembled thanks to Nikko, Trevor, and Cynette. Thanks guys!

- 1/9/20: Only one left that needs to be assembled.

- 1/11/20: All wheels assembled

Summarize number (and type if possible) of motor(s) needed for a full robot check.- 1/9/20: One for deploy, one for the driving of the bars.

Start to figure out what kind of sensors are needed to control the Intake and make sure we do not take in more than 5 balls.- 1/8/20: Beam break that is below the center of the balls. The balls rolling past it breaks the beam, counting the balls.

- Do scaled, dimensioned, CAD sketches to confirm we wil be within our 12" frame extension limit

1/9/20: With the help of Chris Sowden, basic CAD sketches of the two-bar intake system have been made. The current design has us behind the 12 limit.look for foam materials- 3D print more wheels

order polycarbon tubing- intake axils need to be vertically adjustable

Design

- From the prototype we got running at 1/11/2020, here are the measurements that allow for the mecanums to redirect the ball to the center

- Distance from the floor to the mecanum bar: 6.625in

- Distance from frame perimeter to the mecanum bar: 3.9375in

- Distance from frame perimeter to hot dog roller: 9.5625in

- Distance between mecanum axle to hot dog axle: 5.625in

- Distance from floor to the bottom of the bumper: 1.5in

- Distance from floor to center of handoff wheel axle: 8.125in

- Distance from frame perimeter to center of handoff wheel axle: 1.75in

- On 1/12/2020, we experimented with a different hot dog roller which gave us better results. New roller is a 1.25in in diameter roller covered in surgical tubing rubber instead of foam.

- New roller is still grippy enough to grab the balls but it's more slippery and prevents binding between the two rollers. Easier to outtake balls as well.

- 1/14/20 - 1/16/20: ran into a load of issues. Previous iteration was hitting the helix and the centered cut out couldn't handle two balls being intaked at once. Currently testing a design where the bumper cut is to the left of the robot frame if youre looking at the robot from straight on, same side as the shooter. Currently making the prototype to test this new design but waiting on more mecanum wheels to print since the last print failed. Nick V, AJ L, Chris S, Ben D, and others have all worked on the CAD for the pivot mechanism which will be run by a NEO according to our calculations. The same motor will also run the intake --> helix handoff compliance wheel (3green) in a manner similar to our 2016 scalar where the same motors were running the pivot and the movement of the telescoping arm. Lots of work to be done still.

- 3D Printed Hubs are in the left direction!