|

|

| (130 intermediate revisions by 9 users not shown) |

| Line 1: |

Line 1: |

| <u>'''How to Submit Parts'''</u>

| | == How To Submit Parts for Fabrication At Harris == |

|

| |

|

| In order to get parts made a drawing must be completed '''''and''''' the appropriate files must be submitted (see below for drawing and file requirements). Please create a new line in the table FILES TO BE MADE for each part request and email the proper drawing and required files to [mailto:aaverill@harris.com aaverill@harris.com]. Any questions, please ask Amy Averill.<br>

| | Follow the steps below for proper modeling and submittal of parts. It is critical to understand the type of part that is being made (sheetmetal or machined) as this will dictate the model generation along with the types of files that will be required in order to physically make the part. |

|

| |

|

| <br>

| | If you have any questions, please ask Amy Averill (aaverill ---AT--- harris --DOT-- com). |

|

| |

|

| <span style="color: #ff0000"><u>'''Quick Breakdown of Types of Parts/Files Needed'''</u></span>

| | === Steps For Fabrication === |

|

| |

|

| ''Machined Parts'' | | #<span style="color: #ff0000">'''Determine if the part will be a sheetmetal part or a solid part'''</span> |

| | #*''Sheetmetal Parts:'' flat parts with holes that go all the way through the material, bar stock that needs to be cut to length, flat parts that get bent into a shape |

| | #*''Machined Parts:'' pieces with intricate surfaces made from a block of aluminum |

| | #<span style="color: #ff0000">Model the part appropriately depending on if the part is Sheetmetal or Machined from a solid part in Inventor:</span> |

| | #*''Sheetmetal Parts:'' You '''must''' meet very specific requirements in the design of your part! Read the instructions on the [[Sheetmetal Parts at Harris|Sheetmetal at Harris]] page to configure your part for the required bend radius and material thickness! |

| | #*''Machined Parts:'' |

| | #<span style="color: #ff0000">Create the necessary files for fabrication:</span> |

| | #*''Sheetmetal Parts'': Click this link for steps on generating files for '''<span style="font-size: large">[[SHEETMETAL PARTS|Sheetmetal Parts at Harris: Preparing Files for Fabrication]]</span>'''<br/>''-- OR --'' |

| | #*''Machined Parts'': Click this link for steps on generating the files for '''<span style="font-size: large">[[MACHINED PARTS|Machined Part Files and Documents]]</span>''' |

| | #*Be sure to follow the instructions carefully! Your part will be rejected and not made if you do not follow the instructions! |

| | #<span style="color: #ff0000">Have all files checked by a mentor!</span> |

| | #<span style="color: #ff0000">'''Email''' the required files to aaverill ---AT--- harris --DOT-- com.</span> |

| | #*You made the required files in the prior step! |

| | #*;''Sheetmetal Parts'' |

| | #*;*[[SHEETMETAL PARTS|.pdf]] (''[[Fabrication - .pdf|old instructions]]'') |

| | #*;*[[SHEETMETAL PARTS|.dxf]] - '''Must be 2000LT''' (''[[Fabrication - .dxf|old instructions]]'') |

| | #*;''Machined Parts'' |

| | #*;*[[Fabrication - .pdf|.pdf]] |

| | #*;*[[Fabrication - .stp|.stp]] |

| | #Update the Google Drive Part & Assembly log to indicate that the part has been sent to Harris for fabrication. |

|

| |

|

| 1) .dwg

| | <!-- |

| | | {| style="height:50px;width:760px;" border="1" cellspacing="1.5" cellpadding="1" |

| 2) [[Fabrication - .pdf|.pdf]]

| |

| | |

| 3) .stp

| |

| | |

| ''Omax Parts (Sheetmetal)''

| |

| | |

| '' '' 1) .dwg

| |

| | |

| 1) [[Fabrication - .pdf|.pdf]]

| |

| | |

| 2) .dxf

| |

| | |

| See links for what is required in each format and how to save the files.<br>

| |

| | |

| ''' Notice that to save in any of these formats, you must click on "Save Copy As".'''

| |

| | |

| ----

| |

| | |

| [[:Image:3-view controls 1 31 10.pdf|SAMPLE DRAWING]]<br><br>''''''Additional' ''File ''''''Requirements:''' Besides the drawing there are additional files that need to be created in order to store the actual data of the part. Determine if your part is a machined part or cut part and then create the necessary file as listed below.

| |

| | |

| - If the part is a '''machined part''' (think parts made from blocks of aluminum with intricate surfaces) then a '''.stp '''file needs to be created

| |

| | |

| To create a '''.stp'''

| |

| | |

| - Have the part model open (.ipt), go to Save a Copy ---> Save a Copy As ---> Choose file format .stp

| |

| | |

| ''' '''- If the part is a '''cut part''' (think flat parts with holes, bar stock to be cut to length, sheetmetal that gets bent) then a '''.dxf''' file needs to be created. The .dxf

| |

| | |

| is basically a stripped down version of the drawing.

| |

| | |

| ''' '''To create a '''.dxf'''

| |

| | |

| ''* If the part is bent start by changing the model (.ipt) to the flat pattern (unbent version) before creating the new drawing (.idw). When the top''

| |

| | |

| '' view is shown it should be '''in the unbent state'''''

| |

| | |

| - Create a new drawing (.idw) for the part. Show the top view of the part (with all the cutouts, holes, if there are any)

| |

| | |

| - There should be<span style="color: rgb(255,0,0)">''' NO '''</span>borders or templates

| |

| | |

| - There should be no dimensions

| |

| | |

| - Scale the part 1:1

| |

| | |

| - Then use Save a Copy---> Save a Copy As and save as a .dxf Autocad LT.

| |

| | |

| ----

| |

| | |

| <br>

| |

| | |

| Here's an example of how a '''SHEET METAL''' should be sent. It needs two views (folded and flat). The flat view should be clear of everything (template, text, deimensions) while the folded view has all the dimensions needed.

| |

| | |

| This includes:<br>

| |

| | |

| *Overall Dimensions (L, W, H)

| |

| *(For bends) the inner radius and degrees of the bend

| |

| *the length of bends (from the center of the bend to the outer edge of the bent section)

| |

| *properly annotated holes (the example doesn't have a thread and cuts all the way through, so is expressed as a diameter)

| |

| *Thickness and type of metal used (as a note)

| |

| *To keep the drawing clear, write notes on repeated parts (example has 4 of the same bends, and therefore has a note)

| |

| | |

| [[Image:Parts Fabrication Example1.PNG|800px]][[Image:Parts Fabrication Example2.PNG|200px]]

| |

| | |

| ----

| |

| | |

| <br>

| |

| | |

| <u>'''Files to be made'''</u>

| |

| | |

| {| style="width: 700px; height: 45px" border="1" cellspacing="1" cellpadding="1"

| |

| |-

| |

| ! scope="col" | Date

| |

| ! scope="col" | Requested Item

| |

| ! scope="col" | Requestor

| |

| ! scope="col" | Ordered By/Date

| |

| ! scope="col" | QTY

| |

| ! scope="col" | RX'd

| |

| |-

| |

| | 1/19<br>

| |

| | .375 traction spacer<br>

| |

| | Matt M.<br>

| |

| | <br>

| |

| | 4

| |

| | <br>

| |

| |-

| |

| | 1/19<br>

| |

| | .625 traction spacer<br>

| |

| | Matt M.<br>

| |

| | <br>

| |

| | 4<br>

| |

| | <br>

| |

| |-

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| |

| |

| | <br>

| |

| |- | | |- |

| | | | ! scope="col" | Date Files Emailed |

| | <br> | | ! scope="col" | Requested Item (Filename) |

| | <br> | | ! scope="col" | Requestor |

| | <br> | | ! scope="col" | Parts Ordered By/Date |

| | <br> | | ! scope="col" | Quantity Per Robot |

| | <br> | | ! scope="col" | Received Date |

| |-

| |

| |

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| |} | | |} |

|

| |

|

| <br>

| |   |

| | --> |

|

| |

|

| <br> | | <div class="mw-parser-output"> |

| | == How To 3D Print Parts == |

|

| |

|

| <br>

| | Follow the steps below for proper modeling of 3D printed parts. |

|

| |

|

| <br>

| | If you have any questions, please ask Dave. |

|

| |

|

| <u>'''Order Status'''</u> | | === Steps For 3D Printing [https://docs.google.com/document/d/14irjYK9dBww8BxdWR39N614V5eNRXdvq/edit?usp=sharing&ouid=110982024978805285401&rtpof=true&sd=true (Detailed Instructions)] === |

| | <ol style="line-height: 20.7999992370605px;"> |

| | <li>Open the part file you want to 3D Print</li> |

| | <li>Do an Export --> CAD Format</li> |

| | <li>Change the Save As Type to STL Files (*STL)</li> |

| | <li>In the file Dialog press the Options... button.</li> |

| | <li>Make sure the Format is set to Binary.</li> |

| | <li>Set the Units pull down selector to mm.</li> |

| | <li>Set the Resolution to High.</li> |

| | <li>Leave everything else as default.</li> |

| | <li>Press the OK button.</li> |

| | <li>Back in the file dialog navigate to the location you want to save the file and update the file name. Put 3D printer files in ..\02 Build Season (ROBOT)\10 Shop Drawings\3D Printer.</li> |

| | <li>Press the Save button in the file dialog.</li> |

| | <li>Create a drawing of the part and put it in the shop binder.</li> |

| | <li>Uncheck the box for Export Colors</li> |

| | </ol> |

|

| |

|

| {| border="1" cellspacing="1" cellpadding="1" width="700"

| | |

| |-

| |

| ! scope="col" | Date

| |

| ! scope="col" | Requested Item

| |

| ! scope="col" | Requestor

| |

| ! scope="col" | Ordered By/Date

| |

| ! scope="col" | QTY

| |

| ! scope="col" | RX'd

| |

| |-

| |

| ! scope="col" | 1/13/10

| |

| ! scope="col" | 2010 Slot Chassis Brkt

| |

| ! scope="col" | Gannon

| |

| ! scope="col" |

| |

| Averill 1/13/10

| |

| | |

| ! scope="col" | 8

| |

| ! scope="col" | 1/15

| |

| |-

| |

| ! scope="col" |

| |

| 1/13/10

| |

| | |

| ! scope="col" | 2010 Motor Mount SS

| |

| ! scope="col" | Gannon

| |

| ! scope="col" | Averill 1/13/10<br>

| |

| ! scope="col" | 4

| |

| ! scope="col" | 1/15

| |

| |-

| |

| ! scope="col" | 1/13/10

| |

| ! scope="col" | 2010 Rear Moto Cross Brace

| |

| ! scope="col" | Gannon

| |

| ! scope="col" | Averill 1/13/10<br>

| |

| ! scope="col" | 1

| |

| ! scope="col" | 1/15

| |

| |-

| |

| ! scope="col" | 1/13/10

| |

| ! scope="col" | 2010 Bearing Block 3_8ID

| |

| ! scope="col" | Gannon

| |

| ! scope="col" |

| |

| Averill 1/14/10

| |

| | |

| ! scope="col" | 4

| |

| ! scope="col" | 1/18<br>

| |

| |-

| |

| ! scope="col" | 1/15/10

| |

| ! scope="col" | 2010 Camera Mount Sheet 1

| |

| ! scope="col" | Dora

| |

| ! scope="col" | Averill 1/14/10 <br>

| |

| ! scope="col" | 1

| |

| ! scope="col" | 1/18<br>

| |

| |-

| |

| ! scope="col" | 1/18/10

| |

| ! scope="col" | 2010 Camera Mount Bent

| |

| ! scope="col" | Dora

| |

| ! scope="col" |

| |

| Averill 1/14/10

| |

| | |

| ! scope="col" | 1

| |

| ! scope="col" | 1/18<br>

| |

| |-

| |

| ! scope="col" | 2/1/10

| |

| ! scope="col" | Control Box Insert

| |

| ! scope="col" | Controls

| |

| ! scope="col" | Averill 2/1/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/2

| |

| |-

| |

| ! scope="col" | 2/3/10

| |

| ! scope="col" | Battery Case

| |

| ! scope="col" | Dora

| |

| ! scope="col" | Averill 2/4/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/3/10

| |

| ! scope="col" | Motor Mount

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/4/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/3/10

| |

| ! scope="col" | Rear Pulley Support cross member

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/4/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/3/10

| |

| ! scope="col" | Magnet Contact Detector

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/4/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Front Ball Stopper Left

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Front Ball Stopper

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Latch

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Superstructure Gusset

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 2

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Superstructure bolting plate

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Tom Dempsey

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Electromagnet span Sheet Metal

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | HOLD

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" |

| |

| Steel Plate

| |

| | |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | HOLD

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Yoke Flange shaft Support

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 2

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Window Motor Moutning Brakcte

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 2

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Window Motor Reinforcing Bracket

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/5/10

| |

| ! scope="col" | Arresting Cable Bracket

| |

| ! scope="col" | Wolfe

| |

| ! scope="col" | Averill 2/5/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/7/10

| |

| ! scope="col" | 1-02

| |

| ! scope="col" | Shecca

| |

| ! scope="col" | Averill 2/8/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/7/10

| |

| ! scope="col" | 1-03

| |

| ! scope="col" | Shecca

| |

| ! scope="col" | Averill 2/8/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/7/10

| |

| ! scope="col" | 2-01 Ratchet Wheel

| |

| ! scope="col" | Shecca

| |

| ! scope="col" | Averill 2/8/10

| |

| ! scope="col" | 2

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/7/10

| |

| ! scope="col" | 2-03 Ratchet Pawl

| |

| ! scope="col" | Shecca

| |

| ! scope="col" | Averill 2/9/10

| |

| ! scope="col" | 2

| |

| ! scope="col" | 2/11

| |

| |-

| |

| ! scope="col" | 2/9/10

| |

| ! scope="col" | 1-01

| |

| ! scope="col" | Shecca

| |

| ! scope="col" | Averill 2/10/10

| |

| ! scope="col" | 1

| |

| ! scope="col" | 2/11

| |

| |}

| |

| | |

| <br><u>'''Parts Built Elsewhere'''</u>

| |

| | |

| {| border="1" cellspacing="1" cellpadding="1" width="700"

| |

| |-

| |

| ! scope="col" | Date

| |

| ! scope="col" | Part Name

| |

| ! scope="col" | Where to Make

| |

| ! scope="col" | Builder/Date

| |

| ! scope="col" | QTY

| |

| ! scope="col" | RX'd

| |

| |-

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| |-

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| |-

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| |-

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| | <br>

| |

| |}

| |

|

| |

|

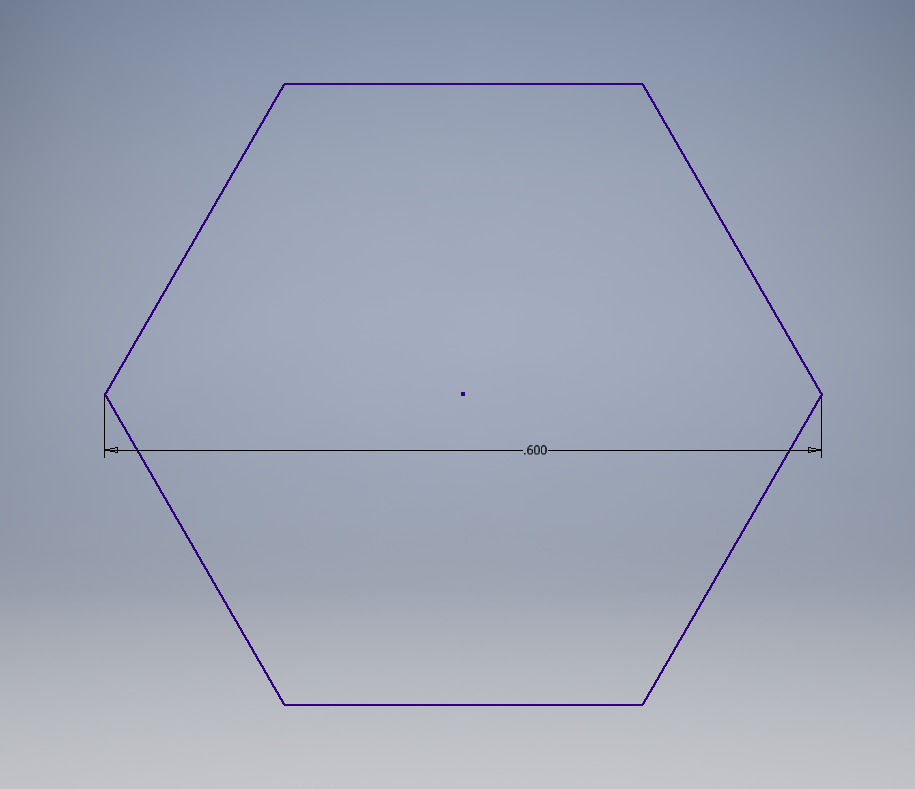

| <br> | | ''<u>NOTE:</u>'' The dimensions for a clearance hole for 1/2 inch hex axle is .60 inches from a corner of the hexagon to the opposite corner, as per photo below. |

|

| |

|

| Notice that RX'd means recieved.

| | [[File:Hexagon.png|RTENOTITLE]] |

| | </div> |

|

| |

|

| == Archives == | | == Archives == |

|

| |

|

| *[[2009:Fabrication|2009 Fabrication Page]] | | *[[2009:Fabrication|2009 Fabrication Page]] |