Fabrication: Difference between revisions

FieldCrate (talk | contribs) No edit summary |

FieldCrate (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

<u>'''How to Submit Parts'''</u> | <span style="color: #ff0000"><u>'''How to Submit Parts'''</u> </span> | ||

In order to get parts made a drawing must be completed '''''and''''' the appropriate files must be submitted (see below for drawing and file requirements). Please create a new line in the table FILES TO BE MADE for each part request and email the proper drawing and required files to [mailto:aaverill@harris.com aaverill@harris.com]. Any questions, please ask Amy Averill.<br> | In order to get parts made a drawing must be completed '''''and''''' the appropriate files must be submitted (see below for drawing and file requirements). Please create a new line in the table FILES TO BE MADE for each part request and email the proper drawing and required files to [mailto:aaverill@harris.com aaverill@harris.com]. Any questions, please ask Amy Averill.<br> | ||

| Line 15: | Line 15: | ||

3) [[Fabrication - .stp|.stp]] | 3) [[Fabrication - .stp|.stp]] | ||

''Omax Parts (Sheetmetal - think flat parts with holes, bar stock to be cut to length, sheetmetal that gets bent)'' | ''Omax Parts (''Sheetmetal - think flat parts with holes, bar stock to be cut to length, sheetmetal that gets bent'')'' | ||

'' '' 1) [[Fabrication - .pdf|.dwg]] | '' '' 1) [[Fabrication - .pdf|.dwg]] | ||

| Line 25: | Line 25: | ||

See links for what is required in each format and how to save the files.<br> | See links for what is required in each format and how to save the files.<br> | ||

''' ''' | ''' ''' | ||

---- | ---- | ||

<br>[[:Image:3-view controls 1 31 10.pdf|SAMPLE DRAWING]]<br><br> | |||

[[:Image:3-view controls 1 31 10.pdf|SAMPLE DRAWING]]<br><br> | |||

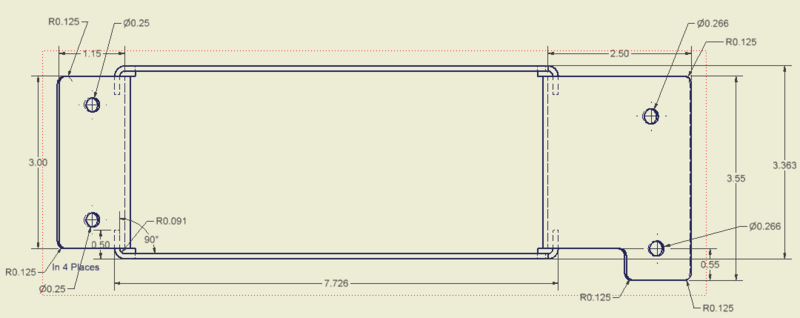

Here's an example of how a '''SHEET METAL''' should be sent. It needs two views (folded and flat). The flat view should be clear of everything (template, text, deimensions) while the folded view has all the dimensions needed. | Here's an example of how a '''SHEET METAL''' should be sent. It needs two views (folded and flat). The flat view should be clear of everything (template, text, deimensions) while the folded view has all the dimensions needed. | ||

Revision as of 06:21, 20 January 2011

How to Submit Parts

In order to get parts made a drawing must be completed and the appropriate files must be submitted (see below for drawing and file requirements). Please create a new line in the table FILES TO BE MADE for each part request and email the proper drawing and required files to aaverill@harris.com. Any questions, please ask Amy Averill.

Quick Breakdown of Types of Parts/Files Needed

Machined Parts (think parts made from blocks of aluminum with intricate surfaces)

1) .dwg

2) .pdf

3) .stp

Omax Parts (Sheetmetal - think flat parts with holes, bar stock to be cut to length, sheetmetal that gets bent)

1) .dwg

1) .pdf

2) .dxf

See links for what is required in each format and how to save the files.

Here's an example of how a SHEET METAL should be sent. It needs two views (folded and flat). The flat view should be clear of everything (template, text, deimensions) while the folded view has all the dimensions needed.

This includes:

- Overall Dimensions (L, W, H)

- (For bends) the inner radius and degrees of the bend

- the length of bends (from the center of the bend to the outer edge of the bent section)

- properly annotated holes (the example doesn't have a thread and cuts all the way through, so is expressed as a diameter)

- Thickness and type of metal used (as a note)

- To keep the drawing clear, write notes on repeated parts (example has 4 of the same bends, and therefore has a note)

Files to be made

| Date | Requested Item | Requestor | Ordered By/Date | QTY | RX'd |

|---|---|---|---|---|---|

| 1/19 |

.375 traction spacer |

Matt M. |

4 | ||

| 1/19 |

.625 traction spacer |

Matt M. |

4 |

||

Order Status

| Date | Requested Item | Requestor | Ordered By/Date | QTY | RX'd |

|---|---|---|---|---|---|

Parts Built Elsewhere

| Date | Part Name | Where to Make | Builder/Date | QTY | RX'd |

|---|---|---|---|---|---|

Notice that RX'd means recieved.