2021:Controls

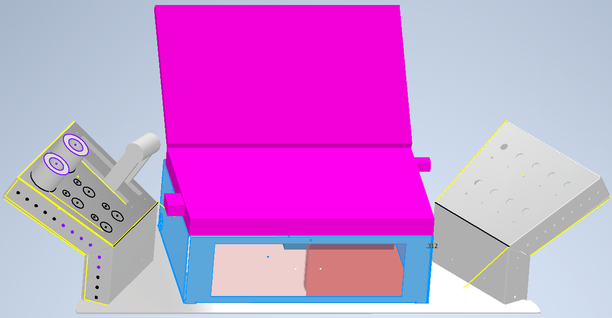

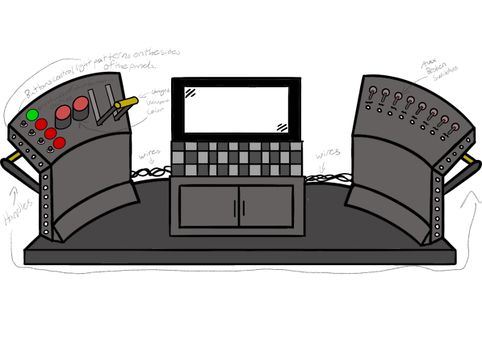

Overall Concept

To do

Not Started

In Process

Completed

- added velcro for power cord

- labelled broken switches (label maker was not printing the full height, so text smaller than desired)

- Create bitmap of Controllers and what their buttons are

- There are Word files in our 2019 Controls folder (under Build Season on the school's Robotics file share)

- Make a copy of these and put them in this years Controls folder (under Build Season)

- look at 'Controller 2 - Aux' table on iomap wiki page (http://penfieldrobotics.com/wiki/index.php?title=2020:Robot_IO_Map)

- these must be Word documents with editable text (i.e. not one big bitmap): neede for when buttons assignments change

- For the Aux pick, we can change it to a white controller; but do that last. for now we just need accurate mappings.

- work with programmers on what the main driver controller buttons are (they were asked to fill it in, so if it isn't go ask them)

- Release 3D Printer Parts for final printing, they are in the 3D printer files folder in the controls. I believe they need part numbers, proper STL files generated (see Dave. W's instructions), and to be added to the spreadsheet.

- DeathStarDoorKnob: This file need to be resized (shrunk) before it's printed, it's 4x the size it's suppose to be (after modification it should be 1" across). Make sure to print two of these.

- Lever: Should be good as is.

- ViewFinder. Make sure to print two of these.

- Sliders

- Mount sliders to the perf board

- Wire up the sliders to a connector

- Aux Joystick

- Design 3D printed knob for new pots [THIS IS OUT #1 PRIORITY]

- find datasheet to get measurements, or look at actual part

- needs to fit over the 'D' shape knob

- needs to fit through hole in Xbox controller

- Mount knobs to joystick.

- Design 3D printed knob for new pots [THIS IS OUT #1 PRIORITY]

- Wire broken switches (will connect to USB joystick board)

- Find LEDs to use for broken switches.

- Figure out way to attach the LEDs to the light pipes.

- Aux controller decided to be white driver to be black

- Add new pots to circuit board (work with Eric)

- Solder in the new pots, make sure to get a consistent orientation

- Secure the pots to the joystick board.

- Add new pots to circuit board (work with Eric)

- Finish STL files for 3D parts and get them in the queue to be printed by the team.

- Come up with concept for bling. Need to make sure that we incorporate the broken switches.

- Need to get pots that fit in the XBox controllers (on order).

- CAD of left and right front panel pieces (inside needs to be 1.5", which will give a 1.75" total thickness (1.5" of inside space plus 2 thickness of metal)

- Copy the left panel panel to create a right panel.

- Order pushbuttons and broken switches.

- Left Panel

- Create viewfinder 3D model

- Finalize lever, generate 3D print files

- Holes for four buttons

- Holes for four button lights (need to determine diameter)

- Add holes to attach viewfinder (need a 'thick' 3D)

- Add cutouts for sliders (wide needs to match the handle)

- Create viewfinder 3D holes

- Add any lettering/cutouts on top edge

- Consider PEM posts to hold in sliders (possibly above and below; would need to move slider cut outs down to be centered top-to-bottom) - Holes added for #6 studs FH-632-4ZI.

- Consider PEM posts in lower/vertical section for PSOC perf board (just keep close together) - Holes added for #6 studs FH-632-4ZI.

- Add TBD cutout for wiring. - Added 0.5" mouse bites

- Need to correct O letter extra (see Cameron)

- Do drawings for model shop - REMEMBER TO ADD NOTES FOR PEMS and welds and where to fold in side for weld

- Paint left panel

- Mount light pipes - hot glue

- Wire LEDs

- Final Assembly - Left Panel

- Make diffusers for viewfinders and bling button lights

- Glue LEDs to light pipes

- Mount bling buttons (get color scheme from Cameron)

- Make diffusers for viewfinders and bling button lights

- need to skuff the bottom side, so it will diffuse the light

- put LED against the lexan and test to make sure the light diffuses ok

- once tested, hot glue diffusers

- hot glue LEDs to diffusers (be sure to not cover holes for buttons and screws

- Wire bling buttons (will connect to PSoC) - add pigtails to four of the buttons with two pin connectors

- Mount viewfinders (after they are 3D printed)

- Mount PSOC board

- Mount the slider perf board (waiting on standoffs from Eric)

- Mount the lever to the sliders

- Final wiring and wire dressing.

- PSoC

- add more pins to PSoC

- need perf board

- add PSoC, so its reset button aligns with hole in vertical part of base

- PIN OUT:

- P0.0 LED signal for light strips (same as previous years)

- P0.1 Upper left button (pin was used in previous years) [blue wire on 6 pin connector - pin 1]

- P4.2 Upper right button (pin was used in previous years) [yellow wire on 6 pin connector - pin 2]

- P0.2 Lower left button [red wire on 6 pin connector - pin 3]

- P0.3 Lower right button [white wire on 6 pin connector - pin 4]

- P3.7 Slider

- add connectors for: LEDs, slider, buttons (6 pin; black is ground)

- add LED wiring (capacitor, resister, etc)

- router USB extension wire (gets connected directly to laptop, needs as much USB power as possible; new cable is in controls drawer)

- Right Panel

- Holes for switches

- Holes for switch LEDs

- Add any lettering/cutouts on top edge

- Add TBD cutout for wiring. - Added 0.5" mouse bites

- Consider PEM posts in lower/vertical section for broken switch board (similar to ones for PSOC perf board on left side) - Holes added for #6 studs FH-632-4ZI.

- Do drawings for model shop - REMEMBER TO ADD NOTES FOR PEMS and welds and where to fold in side for weld

- Paint right panel

- Mount light pipes - hot glue

- Wire LEDs

- Broken switches board (for right panel)

- need perf board

- add 'USB' board

- route USB wire (may need to be extended; gets connected to USB hub)

- Final Assembly - Right Panel

- Glue LEDs to light pipes

- Wire broken switches (will connect to USB joystick board)

- Mount switches

- Mount USB board

- Final wiring and wire dressing

- Base

- Verify overall width with laptop to make sure it doesn't interfere with Ethernet, USB, etc.

- Round edges on base?

- Add holes for pem screws: side panels and laptop base (suggest offseting lower hole on 'button' face because they will bend that in to weld

- Consider small hole (to fits very small screwdriver or paper clip to be able to press PSOC programming button)

- Do drawings for model shop - REMEMBER TO ADD NOTES FOR PEMS

- Paint base

- Final Assembly - Base

- Mount laptop support

- Mount right panel

- Add velcro to bottom of base

- Mount left panel

- Final wiring and wire dressing

- Laptop Stand

- Verify that laptop fits on the stand.

- Add correct PEM holes (https://catalog.pemnet.com/item/pemsert--self-clinching-flush-fasteners---type-f/sert-self-clinching-flush-fasteners-type-f-unified/f-632-1)

- Add hole for charging cable plug (find gromet: "&qid=1579476263&sr=8-26&th=1 https://www.amazon.com/Gardner-Bender-GHG-1575-4-Inch-Grommets/dp/B000BOBW4S/ref=sr_1_26?keywords=grommet%2B1%22&qid=1579476263&sr=8-26&th=1 need 1" hole)

- Consider another 1" grommet hole on right side for USB cables to get to laptop

- maybe add another cut out for USB cables on side???

- Make sure XBox controllers will fit, ditto for the rest of the stuff (laptop brick) (last year's opening was 4" tall; bottom lip was 0.436" from very bottom)

- Figure out the doors (side doors, sliding doors)

- Do drawings for model shop - REMEMBER TO ADD NOTES FOR PEMS and weld (back corners only)

- paint laptop support

- Paint brackets to hold doors

- Mount items in laptop support

- laptop power supply

- USB hub (broken switches and Xbox controllers connect to it)

- Add gromets

- Mount handle

- Mount doors

- Final Assembly - Laptop Support

- Wire dressing for cables - laptop support and XBox controllers

- Doors

- verify cut out for pem

- get 3D model for death knob

- Do drawings for model shop - REMEMBER TO ADD NOTES FOR PEMS and to have 2 made

- Paint doors

- Add knobs to doors

- Map out what LED strips we need (i.e. # of LEDs per) - SEE SECTION BELOW

- panel sides (we will have wires at the bend not LEDs, which means 2 separate strips er panel side)

- bling lights

- view finder

- NOTE: broken switch LEDs will be different as they will be wired with the switch

- Determine perf board size we will need for sliders (it goes inside the panel to hold the sliders up against the top's underside) [needs to be 2.75" x 6.25"]

- it needs cover the slider holes

- needs to be 1/8" beyond the PEM holes that are above ane below the silders

- needs to be 1/4" beyond side of slider holes

- make a CAD piece and add to assembly to make sure the size is correct

- create slider board

- cut perf board to proper size ()

- mount sliding pots so they are center within the cut outs in the panel

- add holes for PEMS

- wire one slider (it will connect to PSoC)

- Think of color scheme [will be all charcol gray, with black 3D printed parts https://www.homedepot.com/p/Rust-Oleum-Painter-s-Touch-2X-12-oz-Satin-Charcoal-Gray-General-Purpose-Spray-Paint-350373/308581515]

- Pick or buy USB HUB

- look at the USB hubs we already have [will go with what we have, just need to pull it. there is a yellow lighting bolt in the 'shield' controls. there are 'X' ones in the drawer in the shop]

- Look for handle

- see what handles we already have (e.g. suit case handle or spring loaded one we have used in the past) you can look at prior year shoping list to find handles we have order before [seem to like the suit case handle we have leftover from prior year, need to confirm the mounting is doable (or find another to order). if we use the suit case one, then we will need a clip to hold the handle up against the laptop support so the controls can be placed on the drivers stations table]

- looking at prior ones (before last year's) so we have a confortable handle

- tenative plan is to mount to base behind laptop support [decided having on side was too 'wide' to be a comfortable carry, either mount directly to base of back of laptop support; not sure if laptop support can handle all the stress since it is thinner than the base and not a fully welded square]

Controls Assignments

Aux

Plan is to use an Xbox controller, but replace the 2 sticks with knobs

- shooter power (knob https://www.digikey.com/product-detail/en/bourns-inc/PTV09A-4025F-B102/PTV09A-4025F-B102-ND/3781133 )

- intake (from floor)

- outtake (from floor)

- spin wheel 3 times

- spin wheel to color specified by FMS

- turret position (knob on Xbox)

- climb: extend arm

- climb: retract arm

- climb: latch hook (if needed)

Bling

- Left panel buttons: https://www.amazon.com/Cylewet-Self-Locking-Latching-Button-CYT1091/dp/B075VBV4QH?ref_=Oct_BSellerC_5739464011_4&pf_rd_p=c0b8340a-5b95-5e70-9244-4375f8dca888&pf_rd_s=merchandised-search-6&pf_rd_t=101&pf_rd_i=5739464011&pf_rd_m=ATVPDKIKX0DER&pf_rd_r=CZCYAFYASCVPTPSCEMTS&pf_rd_r=CZCYAFYASCVPTPSCEMTS&pf_rd_p=c0b8340a-5b95-5e70-9244-4375f8dca888

- 'throttle' from 2 sliders (updated with correct link): https://www.digikey.com/product-detail/en/panasonic-electronic-components/EVA-NF3R15B14/PNF100SB-ND/244381

- Broken swtiches: buy 2 (for a total of 10): https://www.amazon.com/Nilight-Rocker-Toggle-Switch-Waterproof/dp/B078KBC5VH/ref=sr_1_2_sspa?crid=3HY7GNKTX0GP4&keywords=toggle+switch&qid=1579133656&sprefix=toggle%2Caps%2C143&sr=8-2-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEzMkwzNkRWTUswNUI2JmVuY3J5cHRlZElkPUEwOTc1NjcxMUcyWEVNS0g0WDZJOSZlbmNyeXB0ZWRBZElkPUEwNDUyOTAxRFVXWFVSRFJBVzJXJndpZGdldE5hbWU9c3BfYXRmJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

- Main Color for the controls: https://www.homedepot.com/p/Rust-Oleum-Painter-s-Touch-2X-12-oz-Satin-Charcoal-Gray-General-Purpose-Spray-Paint-350373/308581515

Useful Links

- Subteam Student/Mentor Photos

- Zero Delay USB Joystick Encoder

- Joystick Controller Board

- Analog Slide Position

- Example push buttons (need to make sure we pick ones that stay pushed; are not momentary):

- Two USB hub options:

Light strips:

Quantity: 4 - 9 LED light strip

Quantity: 4 - 5 LED light strip

Quantity: 6 - 1 LED light strip

PSoC Install (for lights)

PSoC Creator IDE

Download latest "PSoC Creator" from Cypress (http://www.cypress.com/products/psoc-creator-integrated-design-environment-ide) and install it (use Typical install; at end run Updater and maek sure you have the latest stuff)

For user name and password, you can use: mailme@mailinator.com mailme123

Toolkits and Board Driver Install

Get controls2019 from SVN

Run: vcredist_x86.exe

Run: USBSerialSDKSetup.exe (do Typical install; at end run Updater and maek sure you have the latest stuff)

Run: CY8CKIT04942xxSetupOnlyPackage_revSA.exe (do Typical install; at end run Updater and make sure you have the latest stuff)

While you press and hold the SW1 Prog button on the cypress board, plug in the USB cable to the PC (it will take a while for it to install 5 drivers).

Build/Program

Open PSoC Creator (Start -> Programs -> Cypress -> PSoC Creator -> PSoC Creator)

Open project: File -> Open -> Project/Workspace; then browse to Desktop/FRC2020/trunk/controls/SCB_Bootloader/SCB_Bootloader.cywrk)

Build project: Build -> Build All Projects

While you press and hold the SW1 Prog button on the cypress board, plug in the USB cable to the PC

Download Boot Loader:

- open programmer: Tools -> Bootloader Host

- set 'File' to C:\Users\Robotics\Desktop\FRC2020\trunk\controls\SCB_Bootloader\Bootloadable Blinking LED.cydsn\CortexM0\ARM_GCC_541\Debug\Bootloadable Blinking LED.cyacd

- select the com port for the cypress board

- set Baud to 115200; Data Bits 8; Stop Bits 1; Parity None

- download program: Actions -> Program

Meeting Minutes

1/7

Attendees: Adrian, Jadon, Tanner, Mike, Tristan, Cameron

Work Completed: Brainstormed ideas, came up with favorite design idea and other liked ideas. Complete list of ideas can be viewed at https://docs.google.com/document/d/164eOT3BLDjwwCmvAE6dEmtPM_Dm1WIZeNxB6HL6WMk4/edit?usp=sharing

1/8

Attendees: Adrian, Jadon, Tanner, Dan, Cameron, Tristan

Work Completed: Came up with two improved designs of "Spider-Box" (Plan A and B) that take everyone's suggestions into consideration, started scaled drawing of Plan B (our favorite)

1/9

Attendees: Eric, Byers, MIke, Adrian

Work Completed: Added further detail for the concepts that have been in process and came up with a method to make it. See the Slack channel for a picture.

1/11

Attendees: Eric, Byers, Adrian, Jadon, Tanner, Dan, Cameron,

Work Completed: Went over concepts and got everyone up to speed. Decided on final concept for controls. Started CAD. Figured out that we can put knobs on the Xbox controller. Dissassembled 2018 controls and cleaned up the controls shelf.

1/12

Attendees: Byers, Cameron, Tanner

Work Completed: Worked on bling layout (see overview above). Determined potentiometer for Xbox and ordered. For bing throttle, will use 2 potentiometer slider (they are ordered). Ordered 2 Xbox controllers.

1/14

Attendees: Jadon, Adrian, Tanner, Tristan, Dan, Cameron

Work Completed: Placed space holes on the controls base for the hinges, fixed computer mount design (made as a 3D model before instead of sheet metal), made new assembly with new base and computer mount, started a rough CAD design on a bling panel

1/15

Attendees: Jadon, Cameron, Byers

Work Completed: Xbox controllers and sllider pots came in. Verified Xbox controllers work. Determine depth of side panels needs to be 1.5" (between surfaces). Re-did drawings to be based on Harris template. Cleaned up bling list because some were too big to fit. Added link for broken switches. Fixed CAD designs and changed them from normal sheet metal to harris sheet metal. Updated the bling drawing with a *NEW FEATURE* and found buttons for the bling panel.

1/16

Attendees: Eric

Work Completed: Worked on bling panel.

1/18

Attendees: Cameron, Daniel, Byers, Eric, Tanner, Jadon

Work Completed: Updated the layout. Added details to the bling and Aux panels. Made lever and handle designs. Came to the decision of having one to one led lights on the sides of the panels with smaller LED lenses.

1/19

Attendees: Dan, Byers

Work Completed: properly named files. copied left panel to right & added to assembly. added button holes to left. added button & leds holes to right. round base and sharp corners. narrowed base 2". adjusted laptop base and bent flanges inward. beefed up assembly. added more detail to laptop for connections. corrected power supply & added to assembly. added holes to laptop support.

1/21

Attendees: Jadon, Tanner, Dan

Work Completed: Added Slide holes to left panel. Updated Handel Design and added it to the assembly. Added PEM holes to the base (having trouble aligning them to the laptop support). Found possible USB hub options to be decided on.

1/22

Attendees: Jadon, Cameron, Byers

Work Completed: finished bling panel layout and holes. all pem screw holes on base. adjusted size of lever. verified sizes of buttons & switches. mostly done with wording.

1/23

Attendees: Dan, Tanner, Eric

Work Completed: Made and attached view finder. Added wire holes in the left and right panel covers. Add PEM holes to panel covers. Incresed the size of the laptop support's Xbox opening. Added PSOC pin hole in control base. Centered the laptop support's Xbox opening.

1/25

Attendees: Dan, Jadon, Cameron, Byers, Eric, Tanner

Work Completed: Adjusted holes on multiple pieces. Figured out doors. All CAD is completed and reviewed. Started shop drawings. Finish Base shop drawings.

1/26

Attendees: Dan, Byers, Tanner

Work Completed: Submitted Right Panel Shop Drawing PDF and dxt files. Finished all of the shop drawings and dxf files. Edited door to fix the flange. Started 3D files

1/28

Attendees: Averill, Tanner, Jaden

Work Completed: Started model of XBox knob, mapped out LED light strips, exported all STL files for 3D printing (Eric will print initial copies at work), created STEP files for L3Harris.

1/29

Attendees: Jadon, Cameron, Tristan, Dan, Byers

Work Completed: Found a main color for the controls: https://www.homedepot.com/p/Rust-Oleum-Painter-s-Touch-2X-12-oz-Satin-Charcoal-Gray-General-Purpose-Spray-Paint-350373/308581515; Made CAD model of perf board and added it to the assembly. Made Handle model and decided on it to be located on the back of the controls (not the sides).

1/30

Attendees: Cameron, Tanner, Eric

Work Completed: Worked on Controller knob and lever; made the holes for sliders a little bigger so that the slides actually fit and made the lever a little shorter, put pacman on the controller knob, and put holes in the viewfinder for screws

2/1

Attendees: Cameron, Jadon, Dan, Tanner, Eric, Byers

Work Completed: Rebuilt custom controller, decided AUX controller color was going to be white, wired LED strip

2/2

Attendees: Cameron, Byers, Eric, Dan, Tanner

Work Completed: Updated to-do list, test fitted laptop doors and base, made perf board for sliders, mounted handle, did more LED wiring.

2/4

Attendees: Mike, Jaden, Tanner, Eric

Work Completed: Test fitted the left panel and resized holes in base. Found LEDs for the broken switches and figured how to attach them to the light pipes (heat shrink tubing). Started making pigtails for the broken switches.

2/5

Attendees: Jadon, Dan, Cameron, Byers, Eric

Work Completed: Sodlered up a set of LEDs and gave controls first coat of paint.

2/6

Attendees:

Work Completed:

2/8

Attendees: Byers, Cameron, Jadon, Dan

Work Completed: laptop base mounted, started assembly for both panels

2/9

Attendees: Eric, Byers, Cameron, Dan, Tanner

Work Completed: Right panel is complete. USB hub and controllers mounted. Final wire dressing for laptop support.

2/10

Attendees: Byers, Jadon, Cameron

Work Completed: Hot glued and tested bling panel LEDs (they be lookin kinda fresh), remodeled controller knob for grip support (looks like R2-D2 now) and we have Josh's Seal of Approval for the handle (finally after 3 years)

2/11

Attendees: Eric, Dan, Tanner, Jadon

Work Completed: Mounted the slider (we still need some standoffs to mount to the panel, Eric will get these). Mounted the knobs to the XBox controller.

2/12

Attendees: Byers, Cameron, Jadon

Work Completed: Sanded and glued down the lenses for the lights on bling panel, glued paper in between the lens and LED for less glare, wired ground and other wires to buttons and crimped them into pins, converted 3D parts to STL and uploaded CAD files onto the spreadsheet for printing

2/13

Attendees:

Work Completed:

2/15

Attendees: Jadon, Cameron, Byers

Work Completed: finished wiring PSoC; finish assembly of left panel; debugged bling lights; attached Left panel; finished wire dressing; put on new door knobs

2/16

Attendees: Byers

Work Completed: determined driver controller mapping; created Word docs like we had last year (so we can tweak files); generated bitmaps from Word docs; updated dashboard

2/19

Attendees: Byers

Work Completed: added velcro for power cord; labelled broken switches (label maker was not printing the full height, so text smaller than desired)

Controls Rules

9.10 OPERATOR CONSOLE

R88. The DRIVER Station software provided by National Instruments (install instructions found here) is the only application permitted to specify and communicate the operating mode (i.e. Autonomous/Teleoperated) and operating state (Enable/Disable) to the ROBOT. The DRIVER Station software must be revision 20.0 or newer.

Teams are permitted to use a portable computing device of their choice (laptop computer, tablet, etc.) to host the DRIVER Station software while participating in competition MATCHES.

R89. The OPERATOR CONSOLE, the set of COMPONENTS and MECHANISMS used by the DRIVERS and/or HUMAN PLAYER to relay commands to the ROBOT, must include a graphic display to present the DRIVER Station diagnostic information. It must be positioned within the OPERATOR CONSOLE so that the screen display can be clearly seen during Inspection and in a MATCH.

R90. Devices hosting the DRIVER Station software must only interface with the Field Management System via the Ethernet cable provided at the PLAYER STATION (e.g. not through a switch). Teams may connect the FMS Ethernet cable to their DRIVER Station device directly via an Ethernet pigtail, or with a single-port Ethernet converter (e.g. docking station, USB-Ethernet converter, 9 ROBOT Construction Rules V0 96 of 129 FIRST ® Robotics Competition Thunderbolt-Ethernet converter, etc.). The Ethernet port on the OPERATOR CONSOLE must be easily and quickly accessible.

Teams are strongly encouraged to use pigtails on the Ethernet port used to connect to the FMS. Such pigtails will reduce wear and tear on the device’s port and, with proper strain relief employed, will protect the port from accidental damage.

R91. The OPERATOR CONSOLE must not

A. be longer than 60 in. (~152 cm)

B. be deeper than 14 in. (~35 cm) (excluding any items that are held or worn by the DRIVERS during the MATCH)

C. extend more than 6 ft. 6 in. (~198 cm) above the floor

D. attach to the FIELD (except as permitted by G26)

There is a 54 in. (~137 cm) long by 2 in. (nominal) wide strip of hook-and-loop tape (“loop” side) along the center of the PLAYER STATION support shelf that should be used to secure the OPERATOR CONSOLE to the shelf, per G26. See PLAYER STATION for details.

Please note that while there is no hard weight limit, OPERATOR CONSOLES that weigh more than 30 lbs. (~13 kg.) will invite extra scrutiny as they are likely to present unsafe circumstances.

R92. Other than the system provided by the FIELD, no other form of wireless communications shall be used to communicate to, from, or within the OPERATOR CONSOLE.

Examples of prohibited wireless systems include, but are not limited to, active wireless network cards and Bluetooth devices. For the case of the FIRST Robotics Competition, a motion sensing input device (e.g. Microsoft Kinect) is not considered wireless communication and is allowed.

R93. OPERATOR CONSOLES shall not be made using hazardous materials, be unsafe, cause an unsafe condition, or interfere with other DRIVE TEAMS or the operation of other ROBOTS.